Woodworking plans are the blueprints for your next amazing project. They guide you through every step, from selecting the right wood to finishing touches, ensuring a satisfying and successful build. Whether you’re a seasoned craftsman or just starting out, woodworking plans offer a clear roadmap to achieving your woodworking goals.

From simple shelves to intricate furniture, woodworking plans cover a wide range of projects. Understanding how to read and use them is essential for bringing your creative vision to life. This guide will delve into the world of woodworking plans, equipping you with the knowledge and skills to confidently tackle any project.

Understanding Woodworking Plans

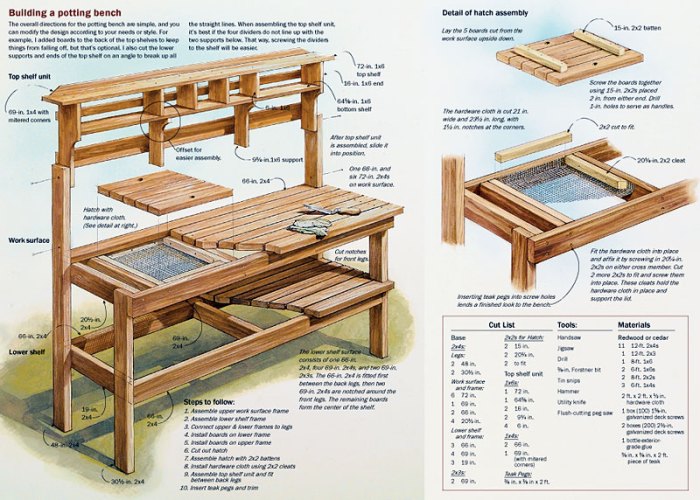

Woodworking plans are detailed blueprints or instructions that guide you through the process of building a specific project. They provide a visual representation of the project, dimensions, materials needed, and step-by-step instructions.

Types of Woodworking Plans

The availability of woodworking plans is vast and diverse, catering to various skill levels and project aspirations.

- Free Plans: Many websites and online communities offer free woodworking plans, often with varying levels of detail and complexity. These plans are a great starting point for beginners or those looking for simple projects.

- Paid Plans: Paid plans often provide more comprehensive and detailed instructions, including cutting lists, assembly diagrams, and even 3D models. These plans are particularly beneficial for complex projects or those requiring precise measurements.

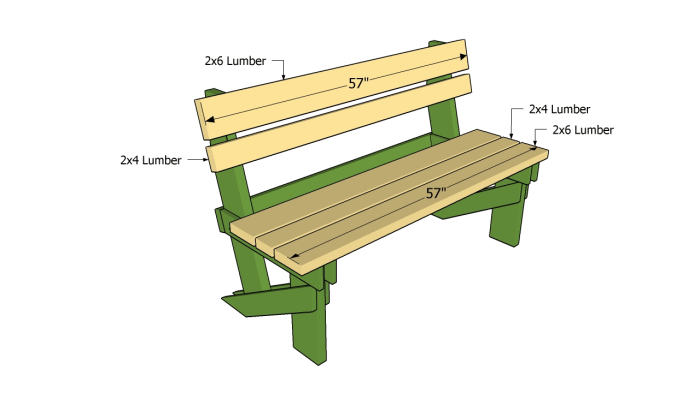

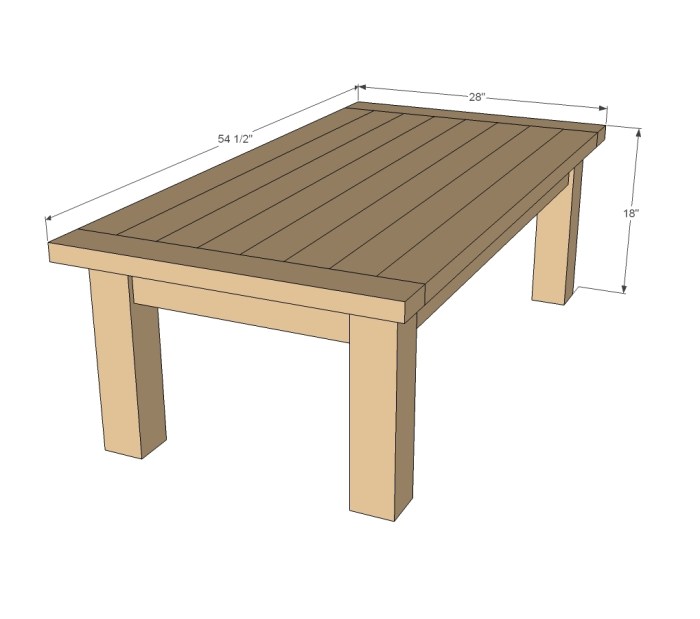

- Project Plans: Project plans focus on specific projects, such as building a bookshelf, table, or chair. They provide a detailed blueprint and instructions tailored to the chosen project.

- Furniture Plans: Furniture plans are specialized plans that focus on building various types of furniture, including cabinets, beds, desks, and more. These plans typically include detailed dimensions, joinery techniques, and finishing instructions.

Choosing the Right Woodworking Plan

Choosing the right woodworking plan is crucial for a successful project. Here are key factors to consider:

- Skill Level: Choose plans that match your woodworking experience. Beginners should start with simple projects, while experienced woodworkers can tackle more complex designs.

- Project Goals: Define your project goals, such as building a specific piece of furniture, a decorative item, or a functional tool. Select plans that align with your desired outcome.

- Time Commitment: Consider the time you are willing to dedicate to the project. Complex plans require more time and effort, while simpler plans can be completed faster.

- Budget: Factor in the cost of materials and tools. Some plans may require specialized tools or expensive materials, while others can be completed with basic equipment and affordable materials.

Reading and Interpreting Woodworking Plans

Woodworking plans are your roadmap to success. They provide detailed instructions and visual representations, guiding you through each step of your project. Understanding these plans is crucial for accurate construction and a satisfying outcome.

Understanding Plan Diagrams

Plan diagrams are visual representations of the project’s layout, showing the overall dimensions and the relationship between different parts. They are typically drawn to scale, allowing you to accurately visualize the final product.

- Orthographic Projections: These diagrams depict the project from multiple viewpoints, such as front, side, and top views. Each view shows the shape and dimensions of the project as if you were looking at it directly from that angle. This helps you understand the overall shape and size of the project and how the different parts fit together.

- Isometric Drawings: These drawings show the project in a three-dimensional perspective, providing a more realistic view of the finished product. This helps you visualize the project from multiple angles and understand its spatial relationships.

- Exploded Views: These diagrams show the project’s components separated and assembled in a logical sequence. They are particularly helpful in understanding how the different parts fit together and the order in which they should be assembled.

Interpreting Drawings and Symbols

Woodworking plans often use symbols and notations to convey specific information. Understanding these symbols is essential for accurately interpreting the plans.

- Dimension Lines: These lines indicate the length, width, and height of different components. The numbers on the lines represent the measurements in inches or millimeters.

- Cutting Lines: These lines show where to cut the wood. They may be solid or dashed, depending on the plan. Solid lines typically indicate a full cut, while dashed lines indicate a partial cut.

- Center Lines: These lines indicate the center of a component or hole. They are often used to guide drilling or cutting operations.

- Arrowheads: These symbols indicate the direction of a cut or the flow of material.

- Notes and Text: Plans often include notes and text that provide additional information about the project, such as material specifications, assembly instructions, or safety precautions.

Safety Precautions

Safety is paramount in woodworking. Always prioritize your well-being by following the safety precautions Artikeld in the woodworking plan. These precautions may include:

- Using appropriate safety equipment: Always wear safety glasses, hearing protection, and a dust mask when working with power tools and wood. Also, use appropriate gloves to protect your hands from splinters and rough edges.

- Maintaining a clean workspace: A cluttered workspace increases the risk of accidents. Keep your work area clean and free of clutter to minimize the risk of tripping or falling.

- Using power tools safely: Always follow the manufacturer’s instructions for using power tools. Never operate a tool without proper training or understanding its safety features.

- Following the plan’s instructions: Woodworking plans are designed to guide you through the project safely. Always follow the instructions carefully and never deviate from the plan without proper knowledge and experience.

Gathering Materials and Tools

Before you can start building your woodworking project, you need to gather the necessary materials and tools. This step is crucial because it ensures you have everything you need to complete the project successfully.

Essential Materials and Tools

Having the right materials and tools is essential for a successful woodworking project. Here’s a table outlining some of the essential materials and tools you’ll need:

| Category | Materials | Tools | Description |

|---|---|---|---|

| Wood | Hardwoods (Oak, Maple, Cherry), Softwoods (Pine, Fir, Spruce), Plywood, MDF | Hand Saws, Circular Saws, Table Saws, Miter Saws | The type of wood you choose will depend on the project and your budget. Hardwoods are durable and beautiful but more expensive. Softwoods are more affordable but less durable. Plywood and MDF are engineered wood products that are often used for construction and furniture. |

| Fasteners | Screws, Nails, Glue | Screwdrivers, Nail Guns, Glue Guns | Fasteners hold the pieces of your project together. Screws are often preferred for their strength and ease of removal. Nails are also common, and glue is used for bonding surfaces. |

| Finishing | Stains, Paints, Varnishes, Polyurethane | Brushes, Rollers, Spray Guns | Finishing protects and enhances the appearance of your project. Stains add color to the wood without hiding the grain. Paints provide a solid color. Varnishes and polyurethane create a protective coating. |

| Safety | Safety Glasses, Ear Protection, Dust Mask | Work Gloves, Safety Boots | Safety is paramount in woodworking. Always wear safety glasses, ear protection, and a dust mask to protect yourself from flying debris and dust. |

Common Woodworking Materials

Woodworking materials are diverse, each with its own properties and applications. Understanding these materials is crucial for selecting the right one for your project.

Hardwoods

Hardwoods are known for their durability, strength, and beauty. They are typically more expensive than softwoods but offer a higher level of quality and longevity. Examples of hardwoods include:

- Oak: Strong, durable, and resistant to scratches and dents. It has a beautiful grain pattern and is often used for furniture, flooring, and cabinets.

- Maple: Known for its hardness, strength, and smooth grain. It is used for furniture, flooring, and musical instruments.

- Cherry: A beautiful wood with a reddish-brown color and a fine grain. It is often used for furniture, cabinets, and trim.

Softwoods

Softwoods are generally less expensive and easier to work with than hardwoods. They are often used for construction, framing, and less demanding projects. Examples of softwoods include:

- Pine: A softwood with a light color and a distinctive grain pattern. It is often used for framing, construction, and furniture.

- Fir: Another softwood with a light color and a straight grain. It is often used for construction, framing, and furniture.

- Spruce: A softwood with a pale color and a fine grain. It is often used for construction, framing, and musical instruments.

Plywood

Plywood is an engineered wood product made by layering thin sheets of wood veneer with alternating grain directions. This construction method creates a strong and stable material that is resistant to warping and cracking. Plywood is commonly used for construction, furniture, and cabinets.

MDF

MDF (Medium-density fiberboard) is another engineered wood product made by combining wood fibers with resin and pressing them into a dense sheet. MDF is smooth and easy to work with, making it suitable for projects requiring a flat surface. It is often used for furniture, cabinets, and trim.

Selecting the Right Tools

Choosing the right tools is essential for completing your woodworking project safely and efficiently. Each tool serves a specific purpose, and using the wrong tool can lead to frustration and poor results.

“The right tool for the job makes the work easier and more enjoyable.”

Essential Woodworking Tools

- Saws: Saws are used for cutting wood. Hand saws are good for basic cuts, while power saws like circular saws, table saws, and miter saws provide more precision and speed.

- Drills: Drills are used for creating holes in wood. They come in various sizes and can be used with different drill bits for specific tasks.

- Sanders: Sanders are used for smoothing and finishing wood surfaces. They come in various types, including belt sanders, orbital sanders, and random orbit sanders, each designed for specific tasks.

- Clamps: Clamps are used to hold pieces of wood together while they are being glued or assembled. They come in various sizes and types, depending on the project.

- Measuring Tools: Measuring tools are essential for accuracy in woodworking. They include rulers, tape measures, squares, and calipers.

Project Preparation and Setup

A well-prepared workspace and project setup are essential for a successful woodworking project. This step ensures you have a safe and organized environment to work in, and it allows you to efficiently cut and prepare your materials according to the plan specifications.

Preparing the Workspace

A well-organized workspace promotes safety and efficiency. Here are some key aspects to consider:

- Clear and Clean: Before you begin, clear your workspace of any unnecessary items and debris. A clutter-free environment reduces the risk of accidents and allows you to focus on your project.

- Adequate Lighting: Ensure you have sufficient lighting to see your work clearly. Good lighting is essential for accurate measurements and cuts.

- Ventilation: Woodworking often involves dust and fumes, so ensure adequate ventilation to maintain a safe and comfortable working environment.

- Work Surface: Choose a stable and sturdy work surface that can support the weight of your project and tools. It should be large enough to accommodate all your materials and tools.

- Safety Equipment: Always wear safety glasses, a dust mask, and hearing protection when working with power tools. This is crucial for protecting yourself from potential hazards.

Setting Up the Project

Once your workspace is ready, it’s time to set up your project. This involves:

- Layout: Carefully lay out all your materials according to the plan specifications. This helps you visualize the project and ensures you have all the necessary components.

- Assembly Sequence: Determine the order in which you will assemble the project. This helps you avoid unnecessary steps and ensures you complete the project in a logical sequence.

- Clamping and Support: Use clamps and supports to secure your workpieces while cutting, drilling, or assembling. This prevents movement and ensures accurate results.

- Tools and Materials: Gather all the tools and materials you will need for the project. This includes power tools, hand tools, fasteners, and any other necessary supplies.

Cutting and Preparing Materials

This step involves accurately cutting and preparing your materials according to the plan specifications.

- Accurate Measurements: Always double-check your measurements to ensure they are accurate. Use a measuring tape, ruler, or combination square for precise measurements.

- Marking Techniques: Use a pencil, marker, or scribing tool to mark your cuts clearly and accurately. Always mark the waste side of the material to avoid damaging the finished surface.

- Cutting Tools: Choose the appropriate cutting tools for your project. This may include a saw, router, table saw, or other power tools. Always use the correct cutting techniques and safety precautions for each tool.

- Sanding and Finishing: After cutting and assembling your project, you may need to sand and finish the surfaces. This can be done using sandpaper, a sanding block, or a power sander. Choose the appropriate sandpaper grit for the desired finish.

Importance of Accurate Measurements and Marking Techniques

Precise measurements and clear markings are crucial for achieving accurate cuts and ensuring the project fits together correctly. Here’s why:

“A single inaccurate measurement can lead to a chain reaction of errors, resulting in a poorly fitting or unusable project.”

- Accurate Cuts: Accurate measurements and markings ensure that your cuts are precise, leading to a well-fitting project.

- Consistent Results: Using consistent marking techniques helps you maintain accuracy throughout the project. This is especially important when working with multiple pieces of wood.

- Avoiding Waste: Precise measurements and markings minimize waste, saving you time and money.

- Professional Finish: Accurate cuts and a clean finish contribute to a professional-looking project.

Construction and Assembly

This is where the fun truly begins! Now that you’ve carefully read your plans and gathered your materials, it’s time to bring your woodworking project to life. Construction and assembly involve putting together all the individual components you’ve prepared into a cohesive, functional piece. This stage requires precision, patience, and a good understanding of woodworking techniques.

Woodworking Techniques

There are several techniques used in woodworking construction and assembly. Each method has its own strengths and weaknesses, and the best choice depends on the specific project and your desired outcome.

- Joinery: This involves creating interlocking joints that hold pieces of wood together without the use of fasteners. Common types of joinery include mortise and tenon, dovetail, and finger joints. These joints are strong, durable, and often add a decorative element to your project.

- Glue-up: Using wood glue to bond pieces of wood together is a simple and effective method. Glue-ups are often used in conjunction with joinery to create a stronger and more stable bond. Ensure you use a high-quality wood glue suitable for the project.

- Screws: Screws are a versatile fastener that can be used to join wood pieces together, creating a strong and secure connection. They are also useful for attaching hardware like hinges, handles, and drawer slides.

- Nails: Nails are another common fastener, often used for temporary or less critical connections. They are typically driven into wood with a hammer. Always choose nails that are appropriate for the wood thickness and the type of project.

Assembling a Simple Project

Let’s imagine you’re building a simple wooden shelf. Here’s a step-by-step guide for assembling it:

- Prepare the shelf boards: Cut the shelf boards to the desired length and width, ensuring the ends are square and smooth. Sand the surfaces for a smooth finish.

- Prepare the side supports: Cut the side supports to the desired height. Mark the locations for the shelf boards on the supports, ensuring they are evenly spaced.

- Create the shelf supports: Use a drill to create pilot holes for the screws that will attach the shelf boards to the side supports. These pilot holes will prevent the wood from splitting when you drive in the screws.

- Assemble the shelf: Align the shelf boards with the marked locations on the side supports. Secure the boards to the supports using wood screws. Ensure the screws are driven in straight and flush with the surface.

- Finishing touches: Once the shelf is assembled, you can sand the entire piece to remove any rough edges and achieve a smooth finish. Apply a stain or paint to enhance the appearance of the shelf, if desired.

Common Mistakes to Avoid

Even experienced woodworkers can make mistakes. Here are some common pitfalls to avoid:

- Incorrect measurements: Double-check your measurements before cutting any wood. A small error can lead to significant problems later in the assembly process.

- Using the wrong tools: Ensure you are using the appropriate tools for the job. For example, don’t use a hammer to drive screws, and don’t use a saw to cut curves.

- Not clamping pieces securely: When gluing pieces together, it’s crucial to clamp them securely to ensure a strong bond. Use clamps that are appropriate for the size and shape of the project.

- Over-tightening screws: Over-tightening screws can damage the wood and weaken the joint. Use a screwdriver or drill with a clutch setting to avoid over-tightening.

Troubleshooting

Even with careful planning and execution, problems can arise. Here are some common issues and their solutions:

- Uneven joints: If your joints are uneven, you may need to adjust the pieces or use shims to create a more even fit. Always check for squareness and use a level to ensure that your project is level.

- Loose joints: If your joints are loose, you may need to add additional glue or fasteners. Consider using a stronger glue or a different type of fastener, such as dowels or biscuits.

- Splitting wood: If the wood splits when you are driving screws, use a drill to create pilot holes before driving the screws. These pilot holes will help prevent the wood from splitting.

Finishing and Refinishing

Finishing is the final stage of woodworking, where you protect and enhance the appearance of your project. It’s a crucial step that transforms raw wood into a beautiful and durable piece. A good finish not only adds visual appeal but also safeguards your work from scratches, moisture, and other environmental damage.

Sanding

Sanding is a fundamental step in preparing your woodworking project for finishing. It smooths the surface, removes imperfections, and creates a uniform texture for the finish to adhere to.

- Start with coarse grit sandpaper (e.g., 80 grit) to remove major flaws and rough spots. Progressively move to finer grits (e.g., 120, 180, 220, 400) for a smoother finish.

- Sand with the grain, following the direction of the wood’s fibers. This ensures a consistent finish and avoids scratches that can mar the final appearance.

- Use a sanding block for consistent pressure and to avoid creating uneven sanding marks.

Staining

Staining is a technique that adds color and depth to wood, enhancing its natural grain patterns.

- Oil-based stains penetrate deeply into the wood, producing rich colors and a durable finish. They are typically slow-drying and may require multiple coats.

- Water-based stains are easier to apply and clean up, but they may not penetrate as deeply as oil-based stains. They also tend to raise the grain of the wood, requiring additional sanding before applying a topcoat.

- Gel stains are thick and creamy, making them ideal for filling in pores and creating a more uniform color.

Painting

Painting is a versatile finishing technique that allows you to add color, texture, and even protective layers to your woodworking projects.

- Choose the right paint type for your project. Latex paints are water-based, easy to clean up, and provide good adhesion. Oil-based paints offer excellent durability and a smooth finish but require solvents for cleanup.

- Prepare the surface properly. Sanding, priming, and cleaning ensure a smooth and even paint application.

- Apply multiple thin coats for a more even and durable finish. Allow each coat to dry completely before applying the next.

Varnishing

Varnishing provides a protective layer that enhances the beauty of wood while safeguarding it from scratches, moisture, and UV damage.

- Polyurethane varnishes are known for their durability and water resistance. They come in both oil-based and water-based formulations.

- Lacquer varnishes are fast-drying and offer a high-gloss finish. They are typically used on furniture and other decorative items.

- Oil-based varnishes penetrate the wood, providing a durable finish that can withstand wear and tear. They are often used on outdoor projects.

Applying a Finish: A Detailed Guide

Let’s focus on applying a polyurethane varnish as an example.

- Prepare your workspace. Choose a well-ventilated area free from dust and debris. Lay down drop cloths or plastic sheeting to protect your work surface.

- Prepare the project. Ensure the wood is clean, dry, and properly sanded. Remove any dust or debris with a tack cloth.

- Choose the right brush or applicator. A natural bristle brush is suitable for oil-based polyurethane, while a synthetic brush works well with water-based formulations. You can also use a foam brush or a spray gun.

- Apply the first coat thinly and evenly. Work with the grain of the wood, using smooth, consistent strokes. Avoid over-applying the varnish, as this can lead to drips and runs.

- Allow the first coat to dry completely. Drying times vary depending on the type of varnish and environmental conditions. Follow the manufacturer’s instructions.

- Sand lightly between coats. Use fine-grit sandpaper (e.g., 220 grit) to smooth out any imperfections and create a smooth surface for the next coat.

- Apply additional coats as needed. Two to three coats are typically sufficient for a durable and protective finish.

Safety Precautions

- Wear appropriate personal protective equipment (PPE). This includes safety glasses, gloves, and a respirator to protect your eyes, skin, and respiratory system from fumes and dust.

- Work in a well-ventilated area. Open windows and doors to allow fresh air to circulate. Use a fan to help remove fumes.

- Store finishes properly. Keep them in tightly sealed containers, away from heat and direct sunlight.

- Dispose of finishes responsibly. Follow local regulations for disposal of hazardous materials.

Woodworking Plan Resources

Finding the right woodworking plans can be the starting point for your next project. Whether you’re a seasoned craftsman or just starting out, having access to a variety of resources can inspire your creativity and help you find the perfect project.

Online Resources

There are many websites dedicated to providing woodworking plans and resources. These websites often offer a wide range of projects, from simple beginner-friendly projects to complex and challenging builds. Some popular websites include:

- Woodworking for Mere Mortals: This website offers a vast collection of free woodworking plans, along with detailed instructions and helpful tips. It’s a great resource for beginners and experienced woodworkers alike.

- Ana White: Ana White’s website is known for its user-friendly plans and tutorials. Her projects are often designed to be budget-friendly and achievable for DIYers.

- The Wood Whisperer: This website features a wide range of woodworking plans, from furniture to toys to outdoor structures. The Wood Whisperer also offers video tutorials and helpful tips for all levels of woodworkers.

- Fine Woodworking: While not entirely free, Fine Woodworking offers a subscription-based service that provides access to a vast library of woodworking plans and articles.

- Popular Woodworking: Similar to Fine Woodworking, Popular Woodworking offers a subscription-based service with access to a wide range of woodworking plans and articles.

Finding Free Woodworking Plans Online

Finding free woodworking plans online is easier than ever. Here are some tips for finding quality free plans:

- Use specific s: When searching for plans online, use specific s to narrow down your results. For example, instead of searching for “woodworking plans,” try searching for “free woodworking plans for a coffee table.”

- Check woodworking forums: Woodworking forums are a great place to find free plans shared by other woodworkers. Many forums have dedicated sections for sharing plans and projects.

- Look for websites specializing in free plans: Several websites are dedicated to providing free woodworking plans. These websites often have a wide range of projects to choose from, categorized by skill level and project type.

- Explore YouTube channels: Many woodworking YouTubers offer free plans and tutorials. These videos can provide valuable insights into the construction process and help you visualize the finished project.

Joining Woodworking Communities and Forums

Joining woodworking communities and forums can be a valuable resource for any woodworker. These online communities offer a platform to connect with other woodworkers, share projects, ask for advice, and learn from experienced craftspeople. Some benefits of joining woodworking communities include:

- Access to a wealth of knowledge: Woodworking communities are filled with experienced woodworkers who are willing to share their knowledge and expertise.

- Inspiration and motivation: Seeing the projects and creations of other woodworkers can inspire you and motivate you to try new things.

- Troubleshooting and support: When you encounter a problem with a project, other woodworkers can offer helpful advice and support.

- Opportunities to learn new techniques: Woodworking communities often host workshops, classes, and events that offer opportunities to learn new techniques and skills.

Closure

With the right plan, the right tools, and a bit of patience, you can create beautiful and functional woodworking projects that you’ll be proud to display. Remember, woodworking is a journey of learning and exploration. Don’t be afraid to experiment, embrace mistakes as learning opportunities, and most importantly, enjoy the process of creating something with your own hands.

Helpful Answers

What is the best way to find free woodworking plans?

There are many websites dedicated to offering free woodworking plans. Popular options include Ana White, Woodworking for Mere Mortals, and The Wood Whisperer. You can also find free plans on platforms like Pinterest and YouTube.

What are some essential woodworking tools for beginners?

A basic set of tools for beginners includes a hand saw, a measuring tape, a combination square, a drill, a screwdriver set, sandpaper, and clamps.

How do I know if a woodworking plan is right for me?

Consider your skill level, the complexity of the project, and the time you have available. Read reviews of the plan, and if possible, look for videos or tutorials that demonstrate the project’s construction.

A woodworking plan is like a roadmap for your project, guiding you through each step. It’s especially helpful for complex projects like building woodworking cabinets , where precise measurements and joinery are crucial. With a detailed plan, you’ll be able to visualize the final product and avoid costly mistakes along the way.