Bench woodworking plans are your gateway to crafting a sturdy and personalized workbench that will elevate your woodworking projects. Whether you’re a seasoned woodworker or just starting out, building your own bench offers a sense of accomplishment and allows you to tailor it perfectly to your needs.

From choosing the right design to selecting materials and assembling the components, these plans provide a comprehensive guide to creating a workbench that will stand the test of time. Get ready to dive into the world of bench woodworking and discover the satisfaction of building your own woodworking haven.

Introduction to Bench Woodworking

A well-built workbench is an essential tool for any woodworker, providing a stable and sturdy platform for cutting, shaping, and assembling projects. It serves as the central hub of your workshop, supporting your work and making your woodworking experience more efficient and enjoyable.

Types of Workbenches

Different types of workbenches cater to specific needs and preferences. Each type offers unique advantages and disadvantages. Here’s a look at some common workbench designs:

- Traditional Workbench: This classic design features a sturdy top made of thick wood, often with a vise and a series of drawers or shelves for storing tools. The traditional workbench is known for its durability and versatility, making it suitable for a wide range of woodworking tasks.

- Mobile Workbench: As the name suggests, this type of workbench is designed for portability, featuring wheels or casters for easy movement around the workshop. Mobile workbenches are ideal for smaller spaces or projects that require working in different locations.

- Folding Workbench: Folding workbenches are compact and easy to store, making them perfect for hobbyists with limited space. These benches typically feature a foldable top and legs, allowing for easy storage when not in use.

- Roubo Workbench: This design, inspired by the 18th-century French cabinetmaker André Roubo, is known for its robust construction and intricate details. It features a massive top, often made of laminated hardwood, and a complex system of vises and dog holes for securing workpieces.

Benefits of Building Your Own Workbench

Building your own workbench offers numerous advantages, including:

- Customization: You can design and build a workbench that perfectly meets your specific needs and preferences, including size, features, and materials.

- Cost Savings: Building your own workbench can be significantly cheaper than purchasing a pre-made one, especially if you source materials from local suppliers or salvage yards.

- Sense of Accomplishment: The satisfaction of building a functional and beautiful workbench with your own hands is a rewarding experience that enhances your woodworking skills.

- Learning Opportunity: Building a workbench provides a valuable learning opportunity, allowing you to gain hands-on experience with various woodworking techniques and tools.

Choosing the Right Bench Design

Building a workbench is a significant investment, both in terms of time and resources. Choosing the right design is crucial for maximizing its functionality and ensuring it meets your specific needs.

Popular Bench Woodworking Plans

A wide range of bench woodworking plans is available online, offering diverse designs and functionalities. These plans often include detailed instructions, material lists, and diagrams, making the construction process more accessible.

- The Workbench by Chris Schwarz: This classic design features a sturdy construction with a robust top and a combination of drawers and shelves for storage. It’s highly versatile and suitable for a wide range of woodworking tasks.

- The Roubo Workbench: Inspired by the traditional French workbench, this design emphasizes strength and durability. It features a massive top, heavy-duty legs, and a variety of integrated tools, making it ideal for heavy-duty woodworking.

- The Sawbench by Paul Sellers: This design focuses on maximizing functionality for hand tool users. It incorporates features like a sawbench, a planing stop, and a variety of workholding options, making it a valuable asset for those who prefer traditional woodworking techniques.

- The Moxon Vice Workbench: This design is known for its unique Moxon vise, which provides exceptional clamping power and versatility. It’s a great option for those who require precise and secure workholding capabilities.

- The Simple Workbench: This design emphasizes simplicity and affordability. It’s a good starting point for beginners and those looking for a basic yet functional workbench.

Bench Design Comparisons

Each bench design offers distinct advantages and disadvantages.

- Work Surface Size: Some benches, like the Roubo, feature large work surfaces, ideal for working on extensive projects. Smaller benches, like the Simple Workbench, are more space-efficient but may limit the size of projects you can accommodate.

- Storage: The availability of drawers, shelves, and other storage options varies between designs. The Workbench by Chris Schwarz offers a balanced combination of storage and work surface area.

- Functionality: Specific features like integrated vises, planing stops, and tool trays enhance the functionality of a workbench. The Sawbench by Paul Sellers is a prime example of a design optimized for hand tool use.

- Construction Complexity: Some designs, like the Roubo, require more complex construction techniques and specialized tools. Simpler designs, like the Simple Workbench, are more accessible for beginners.

- Cost: The cost of building a workbench can vary significantly depending on the chosen design and the materials used. Simple designs using readily available materials tend to be more affordable.

Factors to Consider When Choosing a Bench Design

Several factors influence the choice of a workbench design.

- Workspace Size: The available space in your workshop significantly impacts the bench’s dimensions and design. A small workspace may necessitate a compact design, while a larger space allows for more elaborate configurations.

- Materials: The choice of materials affects the bench’s durability, weight, and overall cost. Hardwoods like maple and cherry are durable and aesthetically pleasing but can be expensive. Softwoods like pine and fir are more affordable but may require more maintenance.

- Intended Use: The type of woodworking you plan to do determines the necessary features and functionality. A bench designed for hand tool use may differ significantly from one intended for power tools and heavy-duty projects.

- Budget: The cost of materials, tools, and hardware can vary significantly. Consider your budget and prioritize features that are essential for your needs.

- Personal Preferences: Ultimately, the best workbench design is one that aligns with your individual preferences and working style. Choose a design that inspires you and makes woodworking enjoyable.

Essential Bench Components

A well-designed workbench is the cornerstone of any woodworking shop, providing a sturdy platform for cutting, assembling, and finishing projects. Understanding the essential components of a workbench is crucial for building a functional and efficient workspace.

The core components of a typical workbench include the base, top, vise, and storage. Each element plays a vital role in supporting the workflow and enhancing the overall functionality of the bench.

Base, Bench woodworking plans

The base of a workbench provides structural support and stability. It typically consists of legs, rails, and bracing. The base should be robust enough to withstand the weight of the top, tools, and materials.

The materials used for the base can vary depending on the desired strength, weight, and budget. Common materials include:

* Wood: Solid hardwood, such as oak, maple, or cherry, offers durability and a classic aesthetic.

* Metal: Steel or aluminum provides exceptional strength and can be easily welded for complex designs.

* Composite: Materials like plywood or MDF offer a cost-effective alternative, especially for large base components.

Top

The workbench top serves as the primary working surface and should be flat, sturdy, and resistant to wear and tear. It should also be able to accommodate various tools and materials.

Common materials for workbench tops include:

* Wood: Hardwoods like maple, cherry, or walnut offer excellent durability and a smooth surface.

* Laminate: Melamine-coated plywood or MDF provides a durable, water-resistant surface.

* Epoxy: Epoxy resin-coated tops offer a smooth, seamless, and highly durable surface.

Vise

A vise is an essential tool for holding and securing workpieces while cutting, drilling, or shaping. It provides a secure grip, freeing up both hands for manipulating tools.

Vises come in various styles, each with its own advantages and disadvantages:

* Front Vise: Mounted on the front edge of the workbench, providing easy access for clamping workpieces.

* Tail Vise: Mounted at the rear of the workbench, ideal for clamping long workpieces.

* Quick-Release Vise: Offers fast and easy clamping and release of workpieces.

* Parallel Vise: Designed for precise alignment of workpieces.

Storage

Storage space is crucial for organizing tools, materials, and accessories, keeping the workbench tidy and efficient. Storage can be incorporated into the workbench design or added as separate units.

Common storage options include:

* Drawers: Provide convenient storage for small tools and accessories.

* Shelves: Ideal for storing larger items, such as lumber or power tools.

* Pegboards: Allow for hanging tools and accessories, maximizing visibility and accessibility.

| Component | Materials | Function |

|---|---|---|

| Base | Wood, Metal, Composite | Provides structural support and stability. |

| Top | Wood, Laminate, Epoxy | Serves as the primary working surface. |

| Vise | Metal | Secures and holds workpieces during cutting, drilling, or shaping. |

| Storage | Wood, Metal, Plastic | Organizes tools, materials, and accessories. |

Building a Bench from Plans

Building a bench from plans is a rewarding experience that allows you to create a custom piece of furniture that perfectly fits your needs and style. The process involves carefully following the instructions provided in the plans, ensuring accuracy and precision in every step. This section will guide you through the process of building a bench from plans, providing a step-by-step approach to help you achieve a successful outcome.

Preparing the Workspace and Materials

Before you begin building, it’s essential to prepare your workspace and gather all the necessary materials. This step sets the foundation for a smooth and efficient construction process.

- Choose a suitable workspace: Select a well-lit and spacious area that allows for comfortable movement and adequate space for your materials and tools. Ensure the workspace is clean and free of any obstacles.

- Gather all materials: Refer to your plans and gather all the required materials, including lumber, hardware, fasteners, and finishing supplies. Double-check the quantity and type of each material to avoid delays during construction.

- Prepare the lumber: Before starting, carefully inspect the lumber for any defects or imperfections. If necessary, use a planer or jointer to smooth and flatten the surfaces. Cut the lumber to the dimensions specified in your plans using a saw, ensuring accuracy and precision.

- Organize your tools: Gather all the tools you will need for the project, such as a saw, drill, screwdriver, measuring tape, level, and clamps. Arrange them in a convenient location within your workspace for easy access during construction.

- Safety first: Always prioritize safety by wearing appropriate safety gear, such as safety glasses, ear protection, and work gloves. Use caution when operating power tools and ensure that your workspace is well-ventilated.

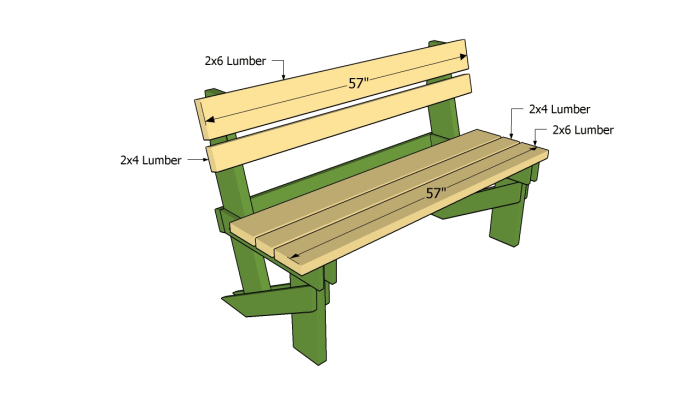

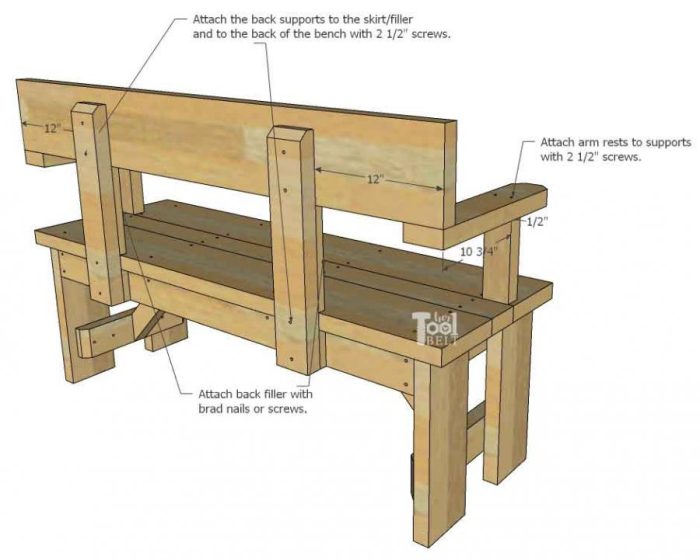

Cutting and Assembling the Bench Components

This step involves cutting and assembling the individual components of the bench according to the plans. Precise cuts and secure joinery are crucial for a sturdy and durable bench.

- Cut the lumber: Use a saw to cut the lumber to the exact dimensions specified in your plans. Mark the cutting lines clearly and make precise cuts to ensure proper fit and alignment of the components.

- Create joinery: Depending on the design of your bench, you may need to create joinery, such as mortise and tenon, dovetail, or pocket holes. Follow the instructions in your plans carefully and use appropriate tools and techniques for each type of joinery.

- Assemble the components: Once all the components are cut and joined, carefully assemble them according to the plans. Use clamps to hold the pieces in place while applying glue or screws for a secure and lasting bond.

- Check for squareness and alignment: After assembling the components, use a level and measuring tape to check for squareness and alignment. Make adjustments as necessary to ensure the bench is structurally sound and visually appealing.

Finishing the Bench

The final step involves sanding, finishing, and adding any decorative details to complete the bench. This step transforms the raw wood into a beautiful and functional piece of furniture.

- Sanding: Sand the bench thoroughly to remove any rough edges, imperfections, and glue residue. Start with a coarse-grit sandpaper and gradually move to finer grits for a smooth and polished finish.

- Applying finish: Choose a finish that complements the style and wood type of your bench. Options include paint, stain, varnish, or oil. Apply the finish according to the manufacturer’s instructions, ensuring even coverage and proper drying time.

- Adding decorative details: If desired, add decorative details, such as hardware, upholstery, or carvings, to enhance the aesthetic appeal of your bench. Follow the plans and your personal preferences when adding these details.

- Final inspection: Once the finish is dry, carefully inspect the bench for any imperfections or areas that need further attention. Make any necessary adjustments or touch-ups to ensure a professional and polished look.

Customizing Your Bench: Bench Woodworking Plans

A workbench is a versatile tool that can be tailored to suit your specific needs and preferences. By adding custom features, you can create a workspace that is both functional and enjoyable to use.

Tool Holders

Tool holders are an essential part of any workbench, providing easy access to your most frequently used tools. There are many different ways to incorporate tool holders into your bench design.

- Magnetic Strips: Magnetic strips can be attached to the sides or front of your workbench to hold metal tools like screwdrivers, chisels, and pliers.

- Pegboards: Pegboards are another popular option for tool storage. You can use hooks, shelves, and other accessories to organize your tools.

- Tool Trays: Tool trays can be mounted to the underside of your workbench or placed on top of the bench to store smaller tools and supplies.

- Hanging Rails: Hanging rails can be installed along the back of your workbench to store larger tools like saws, planes, and hammers.

Drawers

Drawers provide a convenient way to store tools and supplies that you don’t use as often. They can be incorporated into the design of your workbench or added as separate units.

- Built-in Drawers: Built-in drawers can be integrated into the base of your workbench, providing a seamless and organized storage solution.

- Under-Bench Drawers: Under-bench drawers can be added to provide additional storage space without taking up valuable benchtop space.

- Rolling Tool Cabinets: Rolling tool cabinets offer a portable storage solution that can be moved around your workspace as needed.

Work Surfaces

The work surface of your workbench is the most important part of the bench. It should be durable, flat, and easy to clean. There are many different materials that can be used for work surfaces, each with its own advantages and disadvantages.

- Hardwood: Hardwood is a popular choice for work surfaces because it is durable, strong, and easy to work with. Common hardwoods used for workbenches include maple, cherry, and walnut.

- Softwood: Softwoods like pine and fir are less expensive than hardwoods, but they are also less durable. They are often used for workbenches that will not be subjected to heavy use.

- Laminate: Laminate is a durable and affordable material that is often used for work surfaces. It is available in a wide variety of colors and patterns.

- Metal: Metal work surfaces are durable and resistant to scratches and dents. They are often used in industrial settings.

Maintaining Your Bench

Just like any other valuable tool, your workbench requires regular maintenance to ensure it stays in top condition and serves you well for years to come. A well-maintained bench will not only look good but also provide a solid and reliable working surface.

Cleaning Your Bench

Cleaning your workbench regularly is essential to prevent the accumulation of dust, sawdust, and other debris that can interfere with your work and potentially damage the surface.

- Start by removing any loose debris with a brush or a vacuum cleaner.

- For a deeper clean, use a damp cloth to wipe down the surface.

- Avoid using harsh chemicals or abrasive cleaners that could damage the wood.

- After cleaning, allow the bench to dry completely before using it.

Oiling Your Bench

Oiling your workbench helps to protect the wood from moisture, dirt, and scratches, extending its lifespan and enhancing its natural beauty.

- Choose a wood oil specifically designed for workbenches, as these are formulated to penetrate the wood and provide a durable finish.

- Apply the oil evenly to the entire surface of the bench, using a clean cloth.

- Allow the oil to soak into the wood for at least 30 minutes before wiping off any excess.

- Repeat the oiling process every few months, or as needed, depending on the amount of use and the type of wood.

Repairing Common Wear and Tear

Over time, your workbench may show signs of wear and tear, such as scratches, dents, or cracks. Repairing these issues promptly can prevent further damage and maintain the integrity of the bench.

- For minor scratches, use a wood filler or a touch-up pen to match the wood color.

- For dents, use a hammer and a block of wood to gently tap out the dent.

- For cracks, use wood glue to bond the pieces together and clamp them securely until the glue dries.

- If the damage is extensive, it may be necessary to consult a professional woodworker for repair.

Final Thoughts

Building a workbench from plans is a rewarding journey that combines creativity, precision, and a touch of woodworking magic. With the right tools, materials, and a dash of patience, you’ll be able to construct a workbench that will not only serve as a practical work surface but also become a testament to your woodworking skills. So, grab your tools, gather your materials, and get ready to embark on a fulfilling woodworking adventure.

FAQs

What are the most common types of workbench designs?

Popular workbench designs include traditional workbenches, mobile workbenches, and specialized benches for specific tasks like router tables or sanding stations.

What tools do I need to build a workbench?

Essential tools include a saw, drill, measuring tape, clamps, and a level. The specific tools will vary depending on the plan you choose.

How do I choose the right workbench size?

Consider the size of your workshop, the types of projects you’ll be working on, and the amount of storage you need.

Bench woodworking plans can be a great way to build a sturdy and functional workspace. You’ll need to consider what tools and materials you’ll be using and how much space you have available. Once you’ve got the design figured out, don’t forget about woodworking storage ! Keeping your tools organized will make your woodworking experience much more enjoyable and efficient.

With a well-planned bench and a good storage system, you’ll be ready to tackle any woodworking project.