Table furniture plans are your roadmap to crafting stunning and functional tables. Whether you’re a seasoned woodworker or a curious beginner, these plans offer step-by-step guidance and design inspiration to bring your table visions to life.

From the simple elegance of a coffee table to the grandeur of a dining table, table furniture plans encompass a vast array of styles and complexities. They empower you to choose the perfect design, materials, and techniques to match your skill level and desired outcome.

Types of Table Furniture Plans

Table furniture plans are available for various skill levels, from beginner to advanced. The complexity of a plan is determined by the construction techniques, the number of components, and the overall intricacy of the design.

Complexity Levels of Table Furniture Plans

The complexity of table furniture plans can be categorized into three levels: beginner, intermediate, and advanced.

- Beginner plans are ideal for those new to woodworking or furniture building. They typically involve simple designs with straightforward construction techniques and fewer components. An example is a simple, four-legged table with a basic tabletop.

- Intermediate plans are suitable for those with some experience in woodworking. They often feature more intricate designs, requiring advanced techniques like joinery or complex cuts. A coffee table with a drawer or a table with a unique leg design would fall under this category.

- Advanced plans are designed for experienced woodworkers and involve complex designs, intricate joinery, and specialized techniques. These plans might include tables with curved legs, intricate inlays, or complex joinery techniques. An example would be a table with a curved tabletop or a table with intricate carvings.

Materials Used in Table Furniture Plans

Table furniture plans utilize a variety of materials, each with its own properties and aesthetics.

- Wood is a popular material for table furniture due to its natural beauty, durability, and workability. Different wood species offer unique characteristics in terms of color, grain pattern, and hardness. Common woods used in table furniture include oak, maple, cherry, walnut, and pine.

- Metal is another popular material for table furniture, particularly for contemporary and industrial styles. Metal offers durability, strength, and a variety of finishes. Steel, aluminum, and iron are common metals used in table furniture.

- Glass is often used for tabletops, adding a modern and sleek look. Tempered glass is commonly used for its strength and durability. Glass tabletops can be clear, tinted, or patterned.

Examples of Table Furniture Plans

Table furniture plans are available for various table styles, catering to different aesthetics and preferences.

- Farmhouse table plans often feature a rustic aesthetic, with distressed wood finishes and simple, sturdy designs. These tables are known for their durability and practicality.

- Modern table plans emphasize clean lines, minimalist designs, and sleek materials like metal or glass. These tables often feature geometric shapes and contemporary finishes.

- Rustic table plans embrace natural elements and textures, using reclaimed wood or unfinished wood finishes. These tables often have a weathered or distressed look, adding a sense of history and character.

Essential Tools and Materials for Table Furniture Projects

Building a table requires a combination of tools and materials. The right tools make the process smoother and more efficient, while the right materials ensure a durable and aesthetically pleasing final product.

Essential Tools for Table Furniture Projects

The tools required for building a table depend on the complexity of the project. However, a basic set of tools is essential for most table furniture projects.

- Measuring Tools: Measuring tape, ruler, combination square, and a protractor are essential for accurate measurements.

- Cutting Tools: A circular saw, table saw, miter saw, jigsaw, and hand saw are used for cutting wood to size.

- Joining Tools: A drill, screwdriver, clamps, wood glue, and dowel jig are used for assembling the table.

- Finishing Tools: A sander, paint brushes, and sandpaper are used for finishing the table.

- Safety Gear: Safety glasses, ear protection, and a dust mask are crucial for protecting yourself from potential hazards during construction.

Types of Wood Used in Table Furniture Projects

Various types of wood are suitable for table furniture projects, each with its unique characteristics and properties.

- Hardwoods: Hardwoods are generally denser and stronger than softwoods, making them ideal for table tops and legs. Some popular hardwoods for table furniture include oak, maple, cherry, walnut, and mahogany. These woods offer durability, a beautiful grain pattern, and resistance to scratches and dents.

- Softwoods: Softwoods are generally less dense and less expensive than hardwoods. They are often used for table frames and supporting structures. Some popular softwoods for table furniture include pine, fir, cedar, and spruce. These woods are easier to work with and can be stained or painted to achieve different finishes.

- Engineered Woods: Engineered woods are made from wood veneers, fibers, or particles bonded together with adhesives. These materials are more affordable and often more stable than solid wood. Some popular engineered woods for table furniture include plywood, MDF (medium-density fiberboard), and particleboard. They are suitable for table tops, shelves, and other components that require a flat and smooth surface.

Selecting the Right Materials for Specific Table Projects

Choosing the right materials for your table project depends on several factors, including the style, size, and intended use of the table.

- Style: Consider the style of the table you want to build. A rustic table might use rough-cut lumber, while a modern table might use smooth, polished hardwoods or engineered woods.

- Size: The size of the table will influence the type of wood you choose. Larger tables might require stronger and heavier woods, while smaller tables might use lighter and less expensive woods.

- Intended Use: The intended use of the table will determine the durability and finish required. A dining table will need a durable surface that can withstand regular use, while a coffee table might require a more decorative finish.

- Budget: The cost of materials is a significant factor in table furniture projects. Hardwood can be more expensive than softwood or engineered wood, so it’s essential to consider your budget when making your material selections.

Step-by-Step Guide to Building a Table from Plans

Building a table from plans can be a rewarding project that allows you to create a unique piece of furniture for your home. This guide will walk you through the process step-by-step, providing detailed instructions and tips to ensure a successful outcome.

Cutting the Wood

The first step is to cut the wood according to the dimensions specified in your plans. This requires precision and accuracy to ensure the table fits together properly.

- Use a saw, such as a circular saw or a table saw, to make precise cuts. Ensure the saw blade is sharp and the saw is properly aligned.

- Mark the wood carefully using a pencil and a ruler. Double-check your measurements before making each cut.

- If you are working with a table saw, use a push stick to guide the wood safely through the blade. Avoid pushing your fingers near the blade.

- After cutting, check the dimensions of each piece to ensure they are accurate. If necessary, make adjustments with a hand saw or a sander.

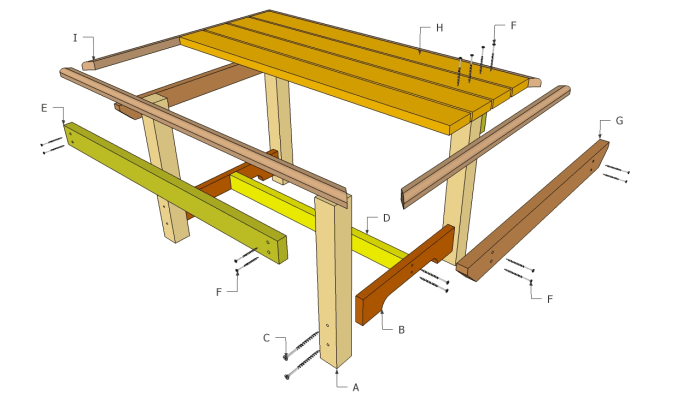

Assembling the Table

Once all the pieces are cut, you can start assembling the table. This step involves joining the pieces together using various techniques, such as screws, dowels, or glue.

- Pre-drill holes for screws to prevent the wood from splitting. Use a drill bit that is slightly smaller than the screw diameter.

- If using dowels, use a doweling jig to create precise holes for the dowels. This ensures the joints are strong and aligned.

- Apply wood glue to the joints before assembling the pieces. Wipe away any excess glue with a damp cloth.

- Clamp the pieces together securely until the glue dries completely. This ensures a strong and stable bond.

Finishing the Table

After assembling the table, it’s time to finish it. This involves sanding the surface, applying a stain or paint, and sealing it with a protective finish.

- Sand the table surface with progressively finer grit sandpaper to create a smooth finish. Start with a coarse grit sandpaper and gradually move to a finer grit.

- Apply a stain or paint to the table according to the manufacturer’s instructions. Use a brush, roller, or spray gun to apply the finish evenly.

- Let the stain or paint dry completely before applying a sealant. A sealant protects the wood from moisture, scratches, and stains.

- Use a clear sealant for a natural finish or a tinted sealant to enhance the color of the wood. Apply the sealant in thin coats, allowing each coat to dry completely before applying the next.

Tips and Tricks for Successful Table Construction

- Plan ahead and gather all the necessary tools and materials before starting the project. This will save you time and prevent frustration.

- Read the plans carefully and understand the construction process before you begin. This will help you avoid mistakes and ensure a successful outcome.

- Use high-quality wood and materials for a durable and long-lasting table. Avoid using cheap or low-quality materials, as they may not hold up over time.

- Take your time and work carefully. Accuracy and precision are essential for a successful table construction project.

- Don’t be afraid to ask for help if you need it. There are many resources available online and in your local community that can provide guidance and support.

Safety Considerations for Table Furniture Projects

Building a table from plans is a rewarding project, but it’s crucial to prioritize safety throughout the process. Woodworking involves sharp tools and potentially hazardous materials, so taking precautions is essential to prevent injuries.

Safety Gear

Wearing appropriate safety gear is fundamental to protecting yourself from potential hazards.

- Eye protection: Always wear safety glasses or goggles to shield your eyes from flying debris, sawdust, and wood chips.

- Hearing protection: Use earplugs or earmuffs to protect your hearing from the loud noise generated by power tools.

- Respiratory protection: A dust mask or respirator is essential for protecting your lungs from inhaling fine wood dust, which can be harmful to your health.

- Gloves: Wear gloves to protect your hands from splinters, cuts, and abrasions.

Tool Safety

Using tools correctly and safely is paramount.

- Power tools: Always unplug power tools when not in use, and keep cords away from sharp edges and moving parts.

- Hand tools: Use tools for their intended purpose and keep them sharp and in good condition.

- Blade and bit safety: Use the correct blade or bit for the task at hand, and always ensure they are securely attached to the tool.

- Tool maintenance: Regularly inspect and maintain your tools to ensure they are in good working order.

Workshop Safety

Maintaining a safe and organized workspace is essential for preventing accidents.

- Clean workspace: Keep your work area clean and free of clutter to avoid tripping hazards.

- Adequate lighting: Ensure you have sufficient lighting to see clearly what you are doing.

- Fire safety: Have a fire extinguisher readily available and be aware of potential fire hazards, such as sawdust and flammable liquids.

- Proper ventilation: Ensure adequate ventilation to remove sawdust and fumes.

Material Safety

Working with wood and other materials involves potential hazards.

- Wood dust: Avoid inhaling wood dust, which can be a respiratory irritant. Use a dust mask or respirator and dispose of dust properly.

- Wood preservatives: Handle wood preservatives carefully, wearing gloves and avoiding contact with skin.

- Glues and finishes: Use glues and finishes in well-ventilated areas and follow the manufacturer’s instructions.

Inspiration and Ideas for Table Furniture Projects: Table Furniture Plans

Building a table can be a rewarding experience, allowing you to create a piece of furniture that perfectly suits your needs and style. But sometimes, getting started can feel overwhelming. This section is dedicated to sparking your creativity and providing inspiration for your next table project.

Examples of Unique and Creative Table Furniture Projects

Unique and creative table designs can transform a space, adding personality and functionality.

- Live Edge Table: These tables feature a natural, uncut edge of the wood, showcasing the wood’s unique grain patterns and character. They can be crafted from a variety of woods, including walnut, maple, and cherry.

- Mid-Century Modern Table: Inspired by the design movement of the mid-20th century, these tables often feature sleek lines, geometric shapes, and minimalist designs. Materials commonly used include wood, metal, and glass.

- Industrial Style Table: With a focus on exposed metal and reclaimed wood, industrial-style tables create a raw and edgy aesthetic. Look for tables featuring metal legs, pipe fittings, and distressed wood surfaces.

- Rustic Farmhouse Table: These tables evoke a sense of warmth and comfort, often featuring chunky wood construction, distressed finishes, and a focus on natural elements.

- Modern Farmhouse Table: Combining the rustic charm of farmhouse style with modern elements, these tables often feature clean lines, minimalist designs, and a blend of wood and metal.

Ideas for Personalizing Your Table Projects

The beauty of building your own table lies in the ability to personalize it to your liking.

- Choose a Unique Wood Species: Explore the characteristics of different wood species, such as color, grain patterns, and durability. Consider using reclaimed wood for a unique and eco-friendly touch.

- Incorporate Unique Design Elements: Add decorative elements like metal accents, inlays, or carving to make your table stand out.

- Customize the Finish: Experiment with different stains, paints, and finishes to achieve the desired look. Consider adding a distressed or weathered effect for a vintage aesthetic.

- Add Storage: Integrate drawers, shelves, or cubbies into your table design to maximize functionality and provide extra storage space.

- Choose the Right Size and Shape: Consider the space you have available and the purpose of the table when selecting its size and shape.

Final Conclusion

With a little planning and the right tools, building a table from plans can be a rewarding and enjoyable experience. The satisfaction of creating a unique piece of furniture that reflects your personal style and craftsmanship is truly unmatched.

Questions Often Asked

What are the best wood types for table construction?

Hardwoods like oak, maple, and cherry are popular choices for their durability and beautiful grain patterns. Softwoods like pine and cedar are easier to work with but may be less durable.

How do I choose the right table plan for my skill level?

Most plans are categorized by difficulty level. Start with beginner plans and gradually work your way up to more complex projects as your skills improve.

What are some common table design styles?

Popular table styles include farmhouse, modern, rustic, industrial, and traditional. Consider your home’s aesthetic and personal preferences when selecting a style.

Where can I find free table furniture plans?

Many websites offer free plans, including Ana White, Woodworking for Mere Mortals, and Instructables. Remember to always check the quality and accuracy of the plans before starting a project.

Table furniture plans are a great starting point for woodworking projects, especially if you’re looking for a project that’s both functional and beautiful. If you’re ready to step up your game, check out these fine woodworking projects for inspiration. Once you’ve got some experience under your belt, you can tackle more complex table designs, like a custom dining table or a beautiful coffee table.