Woodwork shop plans are the blueprints to crafting your own personal haven for woodworking. Whether you’re a seasoned artisan or a curious beginner, having a well-designed shop is crucial for safety, efficiency, and ultimately, creating beautiful projects. From choosing the right equipment to optimizing your workspace, these plans provide a roadmap to building a woodworking shop that meets your needs and inspires your creativity.

This guide will walk you through the essential steps of planning, building, and setting up your woodworking shop. We’ll cover everything from space requirements and equipment selection to safety protocols and maximizing your workspace. Get ready to transform your woodworking dreams into reality!

Introduction to Woodworking Shop Plans: Woodwork Shop Plans

A woodworking shop plan is a blueprint for your workspace, outlining the layout, tools, and equipment you’ll need to safely and efficiently build your woodworking projects.

Having a well-defined plan ensures that you can make the most of your space and maximize your productivity.

Benefits of Woodworking Shop Plans

A well-designed woodworking shop plan offers several advantages, making it a valuable investment for any woodworker, from beginners to seasoned professionals.

- Safety: A well-planned shop layout prioritizes safety by ensuring clear pathways for movement, proper storage for tools and materials, and designated areas for potentially hazardous activities. This minimizes the risk of accidents and injuries.

- Efficiency: By strategically organizing tools and materials, you can save time and effort when working on projects. A planned layout ensures that everything you need is within easy reach, allowing you to focus on your craft.

- Accuracy: A plan provides a framework for accurate measurements and cuts, resulting in more precise and professional-looking projects.

Types of Woodworking Shop Plans

You have several options when it comes to finding woodworking shop plans, each with its own advantages and disadvantages.

- Free Plans: These are readily available online and often offer basic layouts and ideas. However, they may lack the detailed information or customization options that paid plans provide.

- Paid Plans: These plans are usually more comprehensive and detailed, offering specific layouts, tool recommendations, and even 3D models. They often come with professional design support and can be customized to your specific needs.

- Custom Plans: These are created specifically for your unique shop space and requirements. While they can be expensive, they offer the most personalized and tailored solution for your woodworking needs.

Planning Your Woodworking Shop

A well-planned woodworking shop is essential for efficient and safe woodworking. It involves carefully considering your needs, available space, and budget. This section will guide you through the key steps to create a functional and inspiring workspace.

Space Requirements

The first step in planning your woodworking shop is determining the space you need. The size of your shop will depend on the type of woodworking projects you plan to undertake and the equipment you intend to use.

- Project Size: Consider the largest projects you envision, such as building furniture or crafting intricate carvings. This will determine the minimum workspace needed to accommodate the materials and tools involved.

- Equipment Needs: List the essential woodworking equipment you require, including a table saw, planer, jointer, and other tools. Each piece of equipment has specific space requirements for safe and efficient operation.

- Storage: Allocate space for storing lumber, tools, and finished projects. Adequate storage prevents clutter and ensures easy access to materials.

- Work Flow: Consider the flow of your work process. You want to optimize the movement of materials and tools, ensuring a smooth and efficient workflow.

Equipment Needs

The equipment you choose will directly impact your woodworking projects and shop layout. It is essential to prioritize your needs and budget when selecting tools.

- Essential Equipment: A table saw, jointer, planer, and drill press are considered essential for most woodworking projects. These tools provide the foundation for cutting, shaping, and drilling wood.

- Specialized Equipment: Depending on your specific woodworking interests, you may require specialized equipment such as a band saw, router table, or lathe. These tools expand your woodworking capabilities and allow you to tackle more complex projects.

- Hand Tools: Don’t underestimate the importance of hand tools. A well-equipped toolkit with hammers, chisels, saws, and screwdrivers is essential for precise work and completing smaller tasks.

- Safety Equipment: Investing in safety equipment is crucial. This includes dust masks, ear protection, safety glasses, and a first-aid kit. Safety should always be a top priority in your woodworking shop.

Safety Considerations

Safety is paramount in any woodworking shop. By implementing safety measures, you can minimize risks and protect yourself from injuries.

- Dust Control: Woodworking generates dust, which can be harmful to your health. Invest in dust collection systems, such as a dust collector or shop vacuum, to minimize dust exposure.

- Proper Ventilation: Ensure adequate ventilation to remove dust and fumes from the shop. This can be achieved through windows, fans, or a dedicated ventilation system.

- Machine Guards: Always use machine guards provided by the manufacturer to protect you from rotating blades and moving parts.

- Fire Safety: Keep a fire extinguisher readily available and ensure you have a clear escape route in case of a fire. It’s also wise to have a smoke detector installed in your shop.

Layout Options

The layout of your woodworking shop can significantly impact your workflow and efficiency. There are several layout options to consider, each with its advantages and disadvantages.

- Open Floor Plan: An open floor plan provides flexibility and allows for easy movement of materials and tools. However, it can also lead to clutter and a less organized workspace.

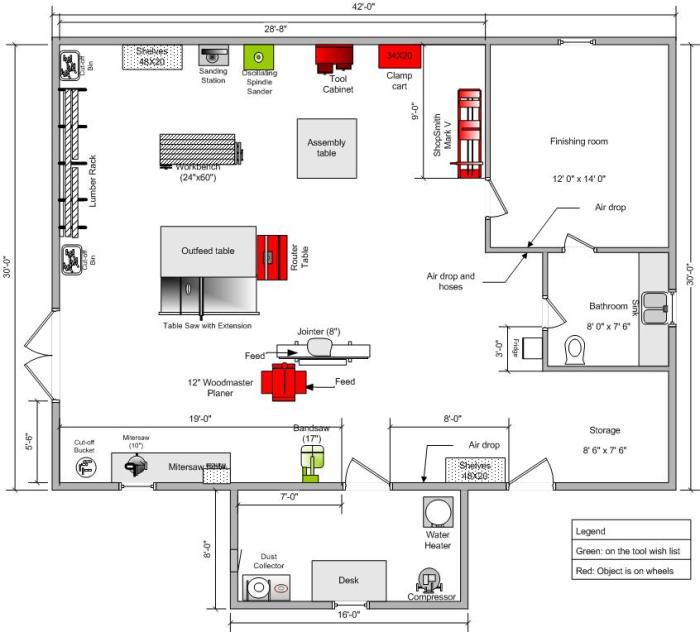

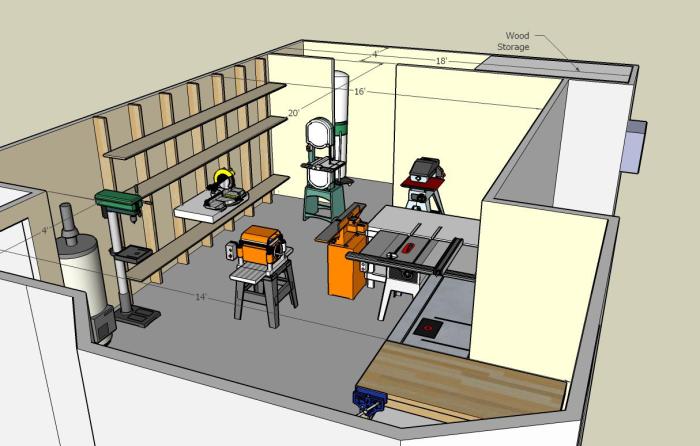

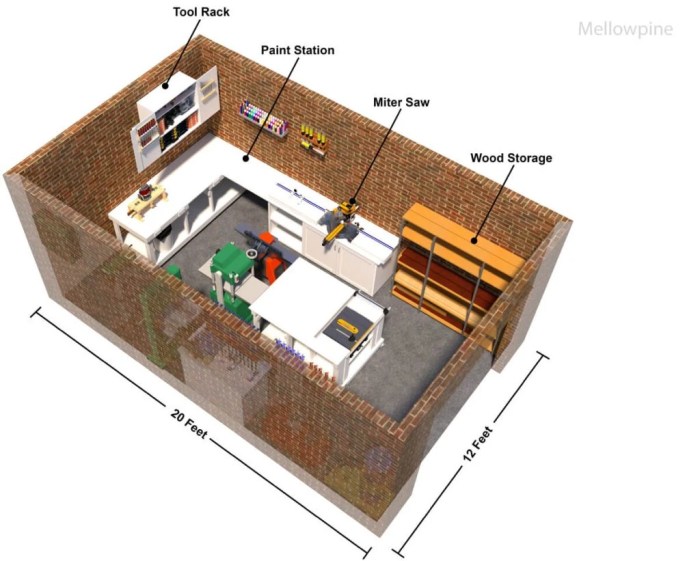

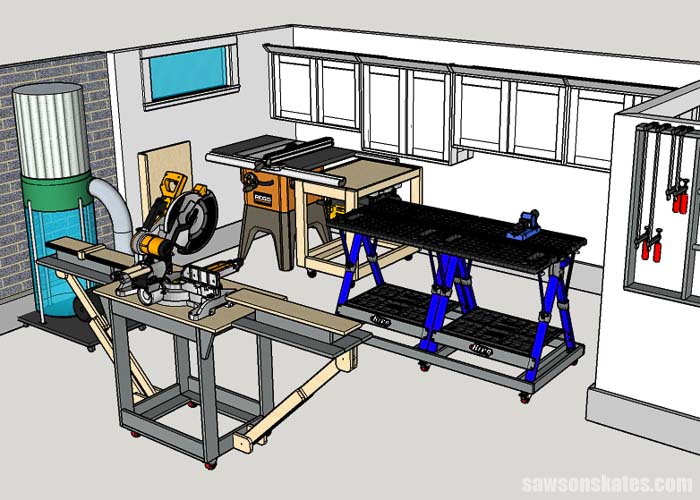

- Dedicated Areas: Dividing your shop into dedicated areas for cutting, sanding, finishing, and storage can create a more organized and efficient workspace. This layout allows you to focus on specific tasks in designated areas.

- Multi-Purpose Spaces: A multi-purpose space can be a good option for smaller shops or those with limited space. This layout combines multiple functions into one area, maximizing space utilization.

Types of Woodworking Projects

The type of woodworking projects you plan to undertake will influence your shop layout, equipment needs, and overall space requirements.

- Small-Scale Projects: If you primarily focus on small-scale projects like birdhouses or simple furniture, a smaller shop with basic equipment may suffice.

- Large-Scale Projects: For large-scale projects like building furniture or cabinets, a larger shop with more extensive equipment is essential.

- Specialized Projects: Specific woodworking projects, such as carving or turning, may require specialized equipment and a dedicated workspace for those activities.

Essential Woodworking Shop Equipment

A well-equipped woodworking shop is essential for any woodworker, regardless of experience level. Having the right tools and machinery can make your projects easier, faster, and more enjoyable. This section will guide you through the essential woodworking shop equipment, including tools, machinery, and safety gear, and provide recommendations for budget-friendly alternatives.

Hand Tools

Hand tools are the foundation of any woodworking shop. They are versatile, portable, and often more precise than power tools.

- Measuring Tools: Accurately measuring and marking your wood is crucial for precise cuts and joints.

- Tape Measure: A must-have for measuring length and width. Choose a tape measure with a durable blade and a locking mechanism.

- Folding Rule: Useful for measuring shorter distances and checking for squareness.

- Combination Square: Provides both a ruler and a protractor for measuring angles and checking squareness.

- Try Square: Used to check for squareness and mark perpendicular lines.

- Bevel Gauge: Transfers angles from one piece of wood to another.

- Marking Tools: Clearly marking your wood is crucial for accurate cuts and joints.

- Pencil: A standard pencil is a versatile tool for marking wood.

- Marking Gauge: Used to mark parallel lines at a specific distance from the edge of the wood.

- Scribing Tool: Creates a line that follows the contour of a surface, useful for transferring shapes.

- Cutting Tools: Cutting tools are essential for shaping and sizing wood.

- Hand Saw: A basic saw for cutting wood, available in various sizes and tooth configurations.

- Backsaw: A saw with a rigid back that provides a more precise cut.

- Coping Saw: Used for cutting intricate curves and shapes.

- Chisels: Used for shaping and carving wood, available in various sizes and shapes.

- Planes: Used to smooth and flatten wood surfaces, available in various sizes and shapes.

- Drilling Tools: Drilling tools are used to create holes in wood.

- Hand Drill: A basic drill for creating holes in wood, available in various sizes and speeds.

- Brace and Bit: A traditional hand-powered drill for creating holes in wood, available in various sizes and shapes.

- Clamps: Clamps are essential for holding pieces of wood together during assembly or while working on them.

- Bar Clamps: Used to hold pieces of wood together at a 90-degree angle.

- C-Clamps: Versatile clamps used for holding pieces of wood together in various configurations.

- Spring Clamps: Small clamps used for holding pieces of wood together during gluing or finishing.

- Other Essential Hand Tools:

- Hammer: Used for driving nails and other fasteners.

- Screwdriver: Used for driving screws.

- Wrench: Used for tightening and loosening nuts and bolts.

- Sandpaper: Used for smoothing and finishing wood surfaces.

- Wood Rasp: Used for shaping and smoothing wood surfaces.

Power Tools

Power tools can significantly enhance your woodworking efficiency and capabilities. While not always essential, they can be highly valuable for specific tasks.

- Power Drill: A versatile tool for drilling holes in wood, available in various sizes and speeds.

- Circular Saw: A powerful tool for cutting wood, available in various sizes and blade configurations.

- Jigsaw: Used for cutting curves and intricate shapes in wood.

- Router: A versatile tool for shaping and trimming wood, available in various sizes and router bit configurations.

- Belt Sander: Used for sanding large flat surfaces, available in various sizes and belt configurations.

- Random Orbit Sander: Used for sanding curves and intricate shapes, available in various sizes and sanding disc configurations.

- Table Saw: A powerful tool for making precise crosscuts and rip cuts in wood, available in various sizes and blade configurations.

- Planer: Used for flattening and smoothing wood surfaces, available in various sizes and configurations.

- Jointer: Used for flattening and smoothing wood edges, available in various sizes and configurations.

- Lathe: Used for turning wood into round shapes, available in various sizes and configurations.

- Scroll Saw: Used for cutting intricate designs in wood, available in various sizes and blade configurations.

Safety Gear

Safety is paramount in any woodworking shop. Always wear appropriate safety gear to protect yourself from injuries.

- Safety Glasses: Protect your eyes from flying debris.

- Dust Mask: Protect your lungs from wood dust.

- Hearing Protection: Protect your ears from loud noise.

- Work Gloves: Protect your hands from cuts and splinters.

- Safety Shoes: Protect your feet from falling objects and sharp tools.

- First Aid Kit: Be prepared for minor injuries.

Budget-Friendly Alternatives

Not everyone can afford the most expensive equipment. Here are some budget-friendly alternatives to consider:

- Used Equipment: You can often find used equipment in good condition at a fraction of the cost of new equipment. Check online marketplaces, local auctions, and woodworking forums.

- Hand Tools: Hand tools are a great way to start your woodworking journey without spending a lot of money.

- Basic Power Tools: You can get started with a few basic power tools, such as a power drill, circular saw, and jigsaw.

- DIY Projects: You can build some woodworking tools and equipment yourself, saving money and gaining valuable experience.

Building a Woodworking Shop

Building a woodworking shop is an exciting endeavor that allows you to create a dedicated space for your woodworking projects. It involves careful planning and execution, and the success of your shop depends on the quality of the construction and the materials used.

Site Preparation

Before starting construction, it’s essential to prepare the site properly. This includes clearing the area of debris, leveling the ground, and ensuring proper drainage. If you’re building on a slope, you may need to create a level foundation or adjust the building’s design to accommodate the slope.

Framing

The framing of your woodworking shop forms the structural backbone of the building. It’s crucial to use high-quality lumber and proper framing techniques to ensure the shop’s stability and longevity. The framing should be strong enough to support the weight of the roof, walls, and any equipment you’ll be installing.

Roofing

The roof protects your woodworking shop from the elements and provides a secure ceiling for your workspace. Choose roofing materials that are durable, weather-resistant, and suitable for your climate. Common roofing options include asphalt shingles, metal roofing, and tile roofing. Proper ventilation is essential to prevent moisture buildup and ensure a comfortable working environment.

Finishing

The finishing touches on your woodworking shop can enhance its appearance and functionality. This may include installing siding, painting the exterior, adding windows and doors, and finishing the interior. You may also want to install electrical wiring, plumbing, and lighting to meet your specific needs.

Types of Woodworking Shop Buildings

The type of woodworking shop building you choose will depend on your budget, space requirements, and personal preferences. Here are some common options:

- Sheds: Sheds are a budget-friendly option that provides a basic workspace. They are typically smaller than garages and may not offer as much insulation or protection from the elements.

- Garages: Garages are often a good choice for woodworking shops because they provide ample space and are typically already equipped with electricity and a door for vehicle access. However, you may need to make modifications to the garage to suit your specific needs.

- Dedicated Workshops: Dedicated workshops are custom-designed buildings specifically for woodworking. They offer the most flexibility and can be tailored to meet your exact requirements. However, they are also the most expensive option.

Setting Up Your Woodworking Shop

Setting up your woodworking shop is crucial for both efficiency and safety. A well-organized shop makes working easier, while a safe shop protects you from potential hazards. This section will guide you through the essential steps of setting up your woodworking shop, focusing on organization, dedicated work areas, and safety procedures.

Organizing Tools

Organization is key to an efficient woodworking shop. A well-organized shop makes it easier to find the tools you need, reduces clutter, and minimizes the risk of accidents. Here are some tips for organizing your tools:

- Invest in tool storage solutions: Tool chests, cabinets, pegboards, and shelves provide dedicated storage for your tools. Choose storage solutions that suit your space and the types of tools you own.

- Group similar tools together: Keep hand tools like chisels, screwdrivers, and wrenches in separate containers. This makes it easier to find the tools you need quickly.

- Label everything: Labeling tool containers, drawers, and shelves helps you find tools easily. Consider using a labeling system that makes sense for you, such as color-coding or using a numbering system.

- Clean and maintain tools regularly: Cleaning and maintaining your tools regularly ensures they function properly and last longer. Sharpen blades, lubricate moving parts, and store tools in a dry place.

Creating Dedicated Work Areas

Creating dedicated work areas in your shop can significantly improve efficiency and safety. By having specific areas for different tasks, you can minimize clutter and reduce the risk of accidents. Here are some examples of dedicated work areas:

- Cutting area: This area should be dedicated to cutting wood and should be equipped with a sawhorse, saw, and other necessary tools. Ensure the cutting area is well-lit and has a clear, open space around it.

- Assembly area: This area is for assembling projects. Provide a sturdy workbench, clamps, and other tools needed for assembly.

- Finishing area: This area is for applying finishes to your projects. Ensure good ventilation and adequate lighting in this area. Consider using a dedicated respirator to protect yourself from fumes.

- Storage area: A designated storage area is essential for storing lumber, materials, and other supplies. Organize your storage area to make it easy to find what you need.

Implementing Safety Procedures

Safety is paramount in a woodworking shop. Implementing safety procedures helps to minimize the risk of accidents and injuries. Here are some essential safety procedures to follow:

- Always wear safety glasses: Woodworking involves flying debris and sawdust, which can cause serious eye injuries. Always wear safety glasses, even when working on small projects.

- Use hearing protection: Loud noises from power tools can damage your hearing over time. Wear hearing protection, such as earplugs or earmuffs, whenever using power tools.

- Keep your workspace clean: A cluttered workspace increases the risk of accidents. Clean up sawdust and debris regularly, and put tools away when you’re finished using them.

- Use appropriate tools for the task: Never use a tool for a task it wasn’t designed for. Use the right tool for the job to ensure safety and prevent damage to your tools.

- Follow manufacturer’s instructions: Always read and follow the manufacturer’s instructions for all tools and equipment. This will help you use them safely and effectively.

- Be aware of your surroundings: Pay attention to your surroundings and be aware of potential hazards. Avoid distractions and keep your mind on the task at hand.

Maximizing Space and Storage

Maximizing space and storage is crucial in a woodworking shop, especially if you have limited space. Here are some tips for making the most of your shop space:

- Use vertical space: Utilize walls and ceilings for storage. Install shelves, pegboards, and cabinets to maximize vertical space.

- Utilize corners: Don’t let corners go to waste. Use corner shelves, cabinets, or workbenches to maximize space.

- Use mobile storage solutions: Mobile tool chests, rolling workbenches, and carts allow you to move tools and equipment around your shop easily, making it easier to access what you need.

- Use multi-purpose furniture: Consider using multi-purpose furniture, such as a workbench that doubles as a storage unit or a folding table that can be used for both work and storage.

Lighting and Ventilation

Adequate lighting and ventilation are essential for a safe and comfortable woodworking shop. Good lighting reduces eye strain and helps you see what you’re doing, while ventilation removes sawdust and fumes. Here are some tips for lighting and ventilation:

- Use multiple light sources: Use a combination of overhead lighting and task lighting to illuminate your workspace adequately. Consider using LED lights, which are energy-efficient and provide bright, clear light.

- Install a dust collection system: A dust collection system removes sawdust and debris from the air, improving air quality and reducing the risk of respiratory problems. Consider a central dust collection system or a shop vacuum.

- Ensure good ventilation: Ensure your shop has adequate ventilation to remove fumes and sawdust. Consider using fans, exhaust hoods, or open windows to improve ventilation.

Safety in the Woodworking Shop

Woodworking is a rewarding hobby or profession, but it also carries inherent risks. A safe woodworking shop is essential for both your well-being and the quality of your work. This section will delve into the importance of safety in the woodworking shop, covering personal protective equipment (PPE), safe operating procedures, common hazards, and a comprehensive list of safety rules and regulations.

Personal Protective Equipment (PPE)

Personal protective equipment (PPE) plays a crucial role in minimizing the risk of injuries in the woodworking shop. It forms a barrier between you and potential hazards, protecting your body from dust, flying debris, and other dangers. Here are some essential pieces of PPE:

- Eye Protection: Safety glasses or goggles are essential for protecting your eyes from flying debris, dust, and wood chips. Always wear them, even for simple tasks.

- Hearing Protection: Earmuffs or earplugs are necessary for reducing noise levels, which can be high in a woodworking shop. Prolonged exposure to loud noises can lead to hearing damage.

- Respiratory Protection: A dust mask or respirator is vital for protecting your lungs from wood dust and other airborne particles. Wood dust can be harmful to your respiratory system and can even cause lung diseases.

- Gloves: Gloves provide protection from sharp edges, splinters, and chemicals. Choose gloves suitable for the task at hand, such as leather gloves for heavy work or nitrile gloves for handling chemicals.

- Foot Protection: Sturdy work boots or shoes with steel toes provide protection from falling objects and other hazards. Ensure they are in good condition and provide adequate support.

Safe Operating Procedures

Following safe operating procedures is crucial for preventing accidents and ensuring a safe woodworking environment. Here are some essential practices:

- Never operate machinery without proper training: Before using any power tools, ensure you understand the operating instructions and safety precautions. Seek guidance from experienced woodworkers or take a woodworking safety course.

- Inspect tools before each use: Regularly check your tools for damage, wear, or loose parts. Replace or repair any faulty tools immediately.

- Use tools for their intended purpose: Avoid using tools for tasks they are not designed for, as this can lead to accidents and damage to the tool.

- Keep your work area clean and organized: A cluttered workspace can be a safety hazard. Regularly clear away debris and store tools properly.

- Maintain a safe distance from moving machinery: Keep a safe distance from rotating blades, spinning bits, and other moving parts. Never reach across moving machinery.

- Use proper lifting techniques: Lifting heavy objects improperly can cause back injuries. Bend your knees, keep your back straight, and lift with your legs, not your back.

- Be aware of your surroundings: Always be aware of your surroundings and potential hazards. Avoid distractions and focus on the task at hand.

- Use appropriate guards and safety devices: Most power tools have safety guards designed to protect you from moving parts. Ensure these guards are in place and functioning correctly.

- Never use power tools when tired or under the influence of drugs or alcohol: Fatigue and impairment can lead to mistakes and accidents. Always work in a clear state of mind.

Common Woodworking Shop Hazards

Woodworking shops present various hazards that require careful attention. Here are some common hazards and how to prevent them:

- Wood Dust: Wood dust can be a respiratory irritant and can also cause lung diseases. Use a dust collection system, wear a dust mask or respirator, and regularly clean your shop to minimize dust accumulation.

- Flying Debris: Flying debris, such as wood chips and splinters, can cause eye injuries. Always wear eye protection, use guards on your tools, and keep your work area clear of debris.

- Sharp Edges and Tools: Sharp edges and tools can cause cuts and lacerations. Always handle sharp tools with care, use gloves, and keep your fingers away from moving blades.

- Heavy Objects: Heavy objects can cause injuries if they fall or are lifted improperly. Use proper lifting techniques, secure heavy objects, and be aware of their weight.

- Electricity: Electrical hazards can lead to shocks or fires. Ensure all electrical cords are in good condition, use GFCI outlets, and avoid using power tools in wet conditions.

- Fire: Fire is a serious hazard in a woodworking shop. Keep flammable materials away from heat sources, have a fire extinguisher readily available, and know how to use it.

- Chemical Hazards: Some woodworking chemicals, such as glues, finishes, and stains, can be hazardous. Use these chemicals in well-ventilated areas, wear gloves, and follow the manufacturer’s instructions.

Safety Rules and Regulations, Woodwork shop plans

A comprehensive set of safety rules and regulations is essential for maintaining a safe woodworking environment. These rules should be clearly communicated to all individuals working in the shop and strictly enforced. Here are some key safety rules:

- No horseplay or distractions: Horseplay and distractions can lead to accidents. Maintain a serious and focused work environment.

- Report all injuries, no matter how minor: Even minor injuries should be reported to ensure proper treatment and prevent further complications.

- Keep the shop clean and organized: A clean and organized shop reduces the risk of accidents. Regularly clear away debris and store tools properly.

- Use only approved tools and equipment: Use tools and equipment that are in good condition and have been approved for use in the shop.

- Follow all safety procedures and instructions: Always follow the safety procedures and instructions provided for each tool and task.

- Wear appropriate personal protective equipment (PPE): Always wear the appropriate PPE for the task at hand, including eye protection, hearing protection, and respiratory protection.

- Never work alone: Always have someone else present in case of an accident. This allows for immediate assistance if needed.

- Be aware of your surroundings: Always be aware of your surroundings and potential hazards. Avoid distractions and focus on the task at hand.

- Know how to use fire extinguishers and first-aid kits: Ensure everyone in the shop knows how to use fire extinguishers and first-aid kits in case of an emergency.

- Post safety rules and regulations in a prominent location: Make sure everyone is aware of the safety rules and regulations by posting them in a visible location.

Woodworking Shop Plans: Resources and Inspiration

Creating a woodworking shop involves meticulous planning and consideration of various factors. From designing the layout to selecting the right tools and equipment, it is crucial to gather inspiration and seek guidance from experienced woodworkers. Fortunately, a wealth of resources and inspiring examples are available to assist you in this endeavor.

Reputable Online Resources

Online resources offer a vast repository of woodworking shop plans, ranging from free to paid options. Exploring these resources can provide valuable insights into different shop layouts, equipment recommendations, and design ideas.

- Woodworking Plans and Projects: Websites like Woodworking for Mere Mortals, Woodworking Magazine, and Popular Woodworking offer a wide range of free and paid woodworking plans. These plans often include detailed instructions, diagrams, and cutting lists, making it easier to build your projects.

- Shop Design and Layout: Websites like Fine Woodworking, The Wood Whisperer, and The Sawdust Maker provide comprehensive articles and videos on designing and planning your woodworking shop. They offer insights into optimizing space, selecting the right equipment, and creating a safe and efficient workspace.

- Online Forums and Communities: Woodworking forums and communities, such as LumberJocks and Reddit’s woodworking subreddit, offer a platform to connect with other woodworkers, share ideas, and seek advice. These platforms can be invaluable for finding inspiration, troubleshooting problems, and getting feedback on your woodworking shop plans.

Inspiring Woodworking Shops

Exploring examples of well-designed woodworking shops can provide valuable inspiration and ideas for your own space. Here are some notable examples:

- The Wood Whisperer Shop: This shop, owned by renowned woodworker Marc Spagnuolo, features a spacious layout with dedicated areas for different woodworking tasks. The shop is well-equipped with a wide range of tools and equipment, including a dust collection system and a dedicated finishing area.

- Fine Woodworking’s Shop: This shop, featured in Fine Woodworking magazine, showcases a meticulously organized workspace with a focus on efficiency and ergonomics. The shop utilizes a combination of traditional and modern woodworking techniques, highlighting the importance of adaptability in a woodworking shop.

- The Sawdust Maker’s Shop: This shop, run by woodworker Steve Ramsey, emphasizes the importance of using readily available materials and tools to create high-quality woodworking projects. The shop features a simple yet functional layout with a focus on practicality and affordability.

Seeking Guidance from Experienced Woodworkers

Connecting with experienced woodworkers can provide invaluable insights and advice as you plan your woodworking shop.

- Local Woodworking Clubs: Joining a local woodworking club can offer opportunities to interact with experienced woodworkers, attend workshops, and learn from their expertise. These clubs often provide access to shared woodworking spaces and resources.

- Woodworking Schools and Workshops: Enrolling in woodworking classes or workshops can provide hands-on training and guidance from experienced instructors. These classes can help you develop your woodworking skills, learn about different tools and techniques, and gain valuable insights into shop design and layout.

- Online Mentoring: Online platforms like Skillshare and Udemy offer courses and mentorship opportunities from experienced woodworkers. These platforms provide access to a wide range of woodworking knowledge and expertise, allowing you to learn at your own pace.

Final Summary

Building your own woodworking shop is a rewarding journey that allows you to create a space uniquely tailored to your craft. With careful planning, the right equipment, and a focus on safety, you can build a workshop that fosters creativity and enables you to bring your woodworking visions to life. Remember, a well-designed shop is not just about tools and space; it’s about creating a space where you can feel inspired, confident, and ready to tackle any woodworking project.

Top FAQs

What are the most important safety considerations for a woodworking shop?

Prioritize safety by using proper personal protective equipment (PPE), like safety glasses, hearing protection, and dust masks. Also, ensure adequate ventilation to remove sawdust and fumes, and follow safe operating procedures for all tools and machinery.

How do I choose the right woodworking shop plan for my needs?

Consider your budget, the type of woodworking projects you plan to undertake, and the available space. Free plans can be a good starting point, while paid plans often offer more detailed designs and professional guidance.

What are some essential woodworking tools for a beginner’s shop?

A basic woodworking shop should include a table saw, a drill press, a jigsaw, a router, a sander, and hand tools like hammers, chisels, and screwdrivers. Start with essential tools and gradually expand your collection as your skills and projects grow.

Woodwork shop plans can be a great starting point for your next project, whether you’re building a simple bookshelf or a complex coffee table. If you’re looking for inspiration and don’t want to spend a lot of money on plans, you can find a ton of free furniture plans online.

Once you’ve found a plan you like, you can adjust it to fit your needs and your woodworking skills. Just remember to always prioritize safety and accuracy when working with wood.