Woodworking plans cabinets offer a rewarding journey for DIY enthusiasts, transforming raw materials into functional and stylish storage solutions. From simple shelves to intricate kitchen cabinets, these plans guide you through every step, allowing you to create pieces that reflect your unique style and enhance your living spaces.

The world of woodworking cabinets is vast and exciting, encompassing a wide array of designs, materials, and construction techniques. Whether you’re a seasoned woodworker or a curious beginner, understanding the fundamentals of cabinet construction is essential. This guide will explore the key aspects of woodworking plans cabinets, empowering you to embark on your own cabinet-building adventures.

Introduction to Woodworking Cabinets

Woodworking cabinets are essential components of furniture and interior design, providing storage, functionality, and aesthetic appeal. They are versatile structures that can be customized to suit various needs and preferences.

The construction of cabinets is a fundamental aspect of woodworking, encompassing various techniques, materials, and design considerations. Understanding the principles of cabinet construction is crucial for creating durable, functional, and visually appealing cabinets.

Types of Woodworking Cabinets

Woodworking cabinets come in diverse forms, each serving a specific purpose and catering to different design aesthetics. The types of woodworking cabinets can be categorized based on their intended use, style, and construction.

- Kitchen Cabinets: These cabinets are designed for storing kitchenware, appliances, and food items. They are typically made of durable materials like plywood, solid wood, or laminate and are available in various styles, including contemporary, traditional, and farmhouse.

- Bathroom Cabinets: Bathroom cabinets are specifically designed for storing toiletries, towels, and other bathroom essentials. They are often made of moisture-resistant materials like waterproof plywood or melamine and feature features like built-in mirrors or shelves.

- Office Cabinets: Office cabinets are used for storing files, documents, and office supplies. They are typically made of sturdy materials like steel or wood and often feature drawers, shelves, and locking mechanisms for security.

- Media Cabinets: Media cabinets are designed for storing electronic devices, such as televisions, DVD players, and gaming consoles. They often feature open shelves, closed cabinets, and wire management systems for easy access and organization.

- Built-in Cabinets: Built-in cabinets are custom-made to fit specific spaces within a room. They are typically designed to integrate seamlessly with the existing architecture and can be used for a variety of purposes, such as storage, display, or creating a focal point.

Woodworking Cabinet Plans: Woodworking Plans Cabinets

Woodworking cabinet plans are essential for anyone looking to build custom cabinets. They provide a detailed blueprint that Artikels every step of the process, from cutting the wood to assembling the final product. A well-designed set of woodworking cabinet plans will help you create beautiful and functional cabinets that will last for years to come.

Detailed Measurements and Specifications

Detailed measurements and specifications are crucial for woodworking cabinet plans. They ensure that all components of the cabinet are cut to the correct size and fit together perfectly. The plans should include:

- Overall dimensions of the cabinet

- Dimensions of each individual component, such as shelves, doors, and drawers

- Locations of all holes, grooves, and other features

- Types of wood to be used for each component

- Hardware specifications, including hinges, handles, and drawer slides

Interpreting and Utilizing Woodworking Cabinet Plans

Interpreting and utilizing woodworking cabinet plans effectively is essential for successful cabinet construction. Here are some tips:

- Review the plans carefully: Before you begin cutting wood, make sure you understand all of the dimensions, specifications, and instructions.

- Create a cutting list: This will help you organize your materials and ensure that you have everything you need.

- Use a measuring tape and a pencil: Accurately measure all components before cutting.

- Follow the instructions carefully: Don’t skip any steps, and take your time to ensure that everything is done correctly.

- Ask for help if you need it: There are many resources available to help you with your woodworking project. If you’re unsure about something, don’t hesitate to ask for help from a more experienced woodworker.

Materials and Tools for Woodworking Cabinets

Building cabinets requires selecting the right materials and tools. This section will guide you through the essential elements for successful cabinet construction, covering both wood types and necessary equipment.

Wood Species for Cabinet Construction

The choice of wood species significantly impacts the cabinet’s appearance, durability, and cost. Here are some commonly used wood species for cabinet construction:

- Hardwoods: These woods are generally denser and more durable than softwoods, making them suitable for cabinet construction. They offer a variety of grain patterns and colors, adding aesthetic appeal. Popular hardwoods for cabinets include:

- Oak: Known for its strength, durability, and distinctive grain pattern. Oak is a popular choice for traditional cabinets and can be stained or painted to achieve various finishes.

- Maple: Maple offers a smooth, close-grained surface that is ideal for painting or staining. It is known for its hardness and resistance to scratches, making it a durable choice for high-traffic areas.

- Cherry: Cherry wood has a warm reddish-brown hue and a fine, even grain. It is prized for its beauty and ability to take a smooth finish. However, cherry is softer than oak or maple, making it less durable in high-wear areas.

- Walnut: Walnut boasts a rich, dark brown color and a distinctive, bold grain pattern. It is a relatively soft wood but offers excellent strength and stability.

- Birch: Birch is a strong and affordable hardwood with a light, creamy color. It is often used for cabinet doors and drawer fronts.

- Softwoods: Softwoods are generally lighter and less expensive than hardwoods. While not as durable, they can be suitable for certain cabinet applications. Some common softwoods used in cabinet construction include:

- Pine: Pine is a softwood with a distinct, knotty grain pattern. It is lightweight and easy to work with, making it a good option for less demanding cabinet projects.

- Cedar: Cedar is known for its aromatic scent and natural insect-repelling properties. It is a softwood that can be used for cabinet construction, particularly in areas where its fragrance is desired.

Comparing Wood Properties

The properties of wood species can influence their suitability for cabinet construction. Here is a comparison of common wood properties:

| Property | Oak | Maple | Cherry | Walnut | Birch | Pine | Cedar |

|---|---|---|---|---|---|---|---|

| Hardness | Hard | Hard | Medium | Medium | Hard | Soft | Soft |

| Durability | High | High | Medium | Medium | High | Low | Low |

| Grain Pattern | Distinctive, open grain | Fine, close grain | Fine, even grain | Bold, distinctive grain | Straight, even grain | Knotty, uneven grain | Straight, even grain |

| Color | Light to dark brown | Light to dark brown | Warm reddish-brown | Dark brown | Light creamy | Light yellow to reddish-brown | Light brown to reddish-brown |

| Workability | Moderate | Moderate | Easy | Easy | Moderate | Easy | Easy |

| Cost | High | Medium | Medium | High | Medium | Low | Low |

Essential Woodworking Tools and Equipment

Building cabinets requires a range of tools and equipment. Here is a list of essential tools for cabinet construction:

- Hand Tools: Hand tools provide precision and control in woodworking. Essential hand tools for cabinet construction include:

- Measuring Tape: Accurate measurement is crucial for precise cabinet construction. Choose a measuring tape with clear markings and a sturdy hook for accurate readings.

- Combination Square: A combination square offers a variety of functions, including measuring angles, marking lines, and checking for squareness. It is an essential tool for accurate cabinet construction.

- Chisels: Chisels are used for shaping and removing wood. They come in various sizes and shapes, depending on the specific task.

- Hand Plane: A hand plane is used for smoothing and leveling wood surfaces. It is a versatile tool that can be used for various tasks, including flattening boards and shaping edges.

- Screwdriver: A screwdriver is essential for assembling cabinet parts. It is important to have both Phillips and flathead screwdrivers in various sizes.

- Hammer: A hammer is used for driving nails and securing joints. A claw hammer is a versatile tool that can also be used for pulling nails.

- Mallet: A mallet is used for striking chisels and other tools without damaging the wood. It is a softer alternative to a hammer.

- Power Tools: Power tools can significantly speed up the cabinet construction process. Some essential power tools include:

- Circular Saw: A circular saw is used for cutting wood to length and making straight cuts. Choose a saw with a blade guard for safety.

- Jigsaw: A jigsaw is used for cutting curved shapes and intricate designs in wood. It is a versatile tool that can be used for a variety of cabinet construction tasks.

- Router: A router is used for shaping edges, creating grooves, and creating decorative details. It is a powerful tool that requires careful handling.

- Drill Press: A drill press provides accuracy and stability for drilling holes in wood. It is essential for cabinet construction, as it ensures that holes are drilled at the correct angle and depth.

- Belt Sander: A belt sander is used for sanding large surfaces quickly and efficiently. It is a powerful tool that can be used for smoothing and leveling wood surfaces.

- Random Orbit Sander: A random orbit sander is used for sanding smaller areas and creating a smooth finish. It is a versatile tool that can be used for various cabinet construction tasks.

- Safety Equipment: Safety should always be a priority when working with woodworking tools. Essential safety equipment includes:

- Safety Glasses: Safety glasses protect your eyes from flying debris. Wear them at all times when using woodworking tools.

- Hearing Protection: Power tools can produce loud noise levels. Wear hearing protection to protect your ears from damage.

- Dust Mask: Woodworking can generate dust, which can be harmful to your lungs. Wear a dust mask to protect your respiratory system.

- Work Gloves: Work gloves protect your hands from cuts and splinters. They also provide a better grip on tools.

- Measuring and Marking: Begin by carefully measuring the dimensions of your cabinet design. Transfer these measurements to your wood using a pencil and a ruler or measuring tape. Mark the cut lines clearly and precisely.

- Choosing the Right Saw: The type of saw you use will depend on the type of wood and the complexity of the cuts. For straight cuts, a table saw or circular saw are efficient choices. For intricate cuts or curves, a jigsaw or band saw might be more suitable.

- Making Accurate Cuts: When using a table saw, use a push stick to guide the wood through the blade safely. When using a circular saw, make sure to guide the saw along a straight edge for accurate cuts. Always ensure that the blade is sharp and the saw is properly adjusted for the type of wood you are cutting.

- Pocket Hole Joinery: Pocket hole joinery is a popular method for assembling cabinets. Pocket holes are drilled at an angle on the edge of the wood, allowing for screws to be driven in from the inside, creating a strong and hidden joint. This method is relatively easy to master and requires minimal tools.

- Dowel Joinery: Dowel joinery uses wooden dowels to connect two pieces of wood. Holes are drilled at precise locations on both pieces, and the dowels are glued into the holes, creating a strong and aesthetically pleasing joint. This technique requires a bit more precision than pocket hole joinery but results in a more refined appearance.

- Mortise and Tenon Joinery: Mortise and tenon joinery is a traditional method that involves creating a rectangular hole (mortise) in one piece of wood and a corresponding tongue (tenon) on the other piece. This technique creates a strong and durable joint that is often used for furniture making. It requires more skill and time than other methods but produces a very robust joint.

- Dry Fit: Before applying glue, always do a dry fit of the cabinet components. This ensures that all the pieces fit together correctly and that the cabinet is square.

- Applying Glue: Apply a thin, even coat of wood glue to the surfaces that will be joined. Avoid using too much glue, as it can ooze out and create a messy finish.

- Clamping: Clamp the cabinet components together firmly and evenly. Ensure that the clamps are properly positioned to prevent warping or distortion. Leave the clamps in place until the glue is fully cured.

- Finishing Touches: Once the glue has dried, remove the clamps and clean up any excess glue. You can then sand the cabinet smooth and apply a finish to protect the wood and enhance its appearance.

- Panel Doors: Panel doors are a classic choice for cabinets. They consist of a frame that surrounds a flat panel. The panel can be made from various materials, such as plywood, MDF, or solid wood. Panel doors offer a clean and traditional look.

- Raised Panel Doors: Raised panel doors are similar to panel doors but have a raised center panel. This adds a touch of elegance and sophistication to the cabinet. The raised panel can be created by using a router to cut a groove around the perimeter of the panel.

- Flush Doors: Flush doors have a smooth surface without any raised or recessed panels. They offer a modern and minimalist look and are easy to clean. Flush doors can be made from plywood, MDF, or solid wood.

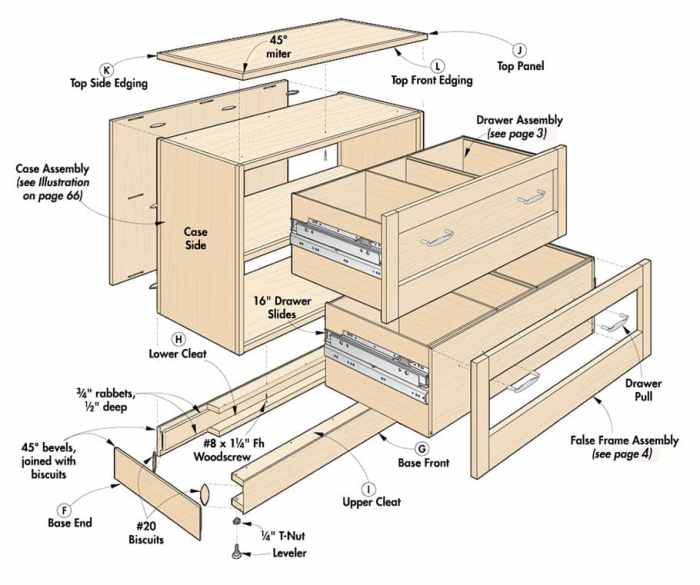

- Drawer Box Construction: Drawer boxes are typically constructed from plywood or solid wood. The sides, bottom, and front are joined together using rabbet joints, dado joints, or pocket hole joinery. The back of the drawer box is often made from thin plywood or a decorative piece of wood.

- Drawer Slides: Drawer slides allow the drawer to move smoothly and easily. There are various types of drawer slides available, including side-mounted slides, under-mount slides, and full-extension slides. The type of slide you choose will depend on the weight of the drawer and your budget.

- Drawer Front: The drawer front is the visible part of the drawer and can be made from solid wood, plywood, or MDF. It should be sized to fit the drawer box and the drawer slides. The drawer front can be attached to the drawer box using screws or a dado joint.

- Shelf Construction: Shelves are typically made from plywood, MDF, or solid wood. They should be cut to the desired width and depth of the cabinet. The edges of the shelves can be finished with a router or sandpaper to create a smooth and professional look.

- Shelf Supports: Shelves are supported by shelf pins, shelf cleats, or brackets. Shelf pins are small metal pins that are inserted into holes drilled in the cabinet sides. Shelf cleats are pieces of wood that are attached to the cabinet sides to support the shelves. Brackets are metal supports that are attached to the cabinet sides and the shelves.

- Paint: This is the most common cabinet finish. It offers a wide range of colors and can be easily applied with a brush, roller, or sprayer. Paint provides a durable, washable surface and is a good choice for high-traffic areas.

- Stain: Stains penetrate the wood’s surface, enhancing its natural grain pattern and color. They are available in various colors and finishes, including oil-based, water-based, and gel stains. Stains are less durable than paint but offer a more natural look.

- Varnish: Varnish is a clear, protective coating that enhances the wood’s natural beauty. It comes in gloss, semi-gloss, satin, and matte finishes. Varnish is durable and water-resistant, making it a good choice for kitchen cabinets.

- Lacquer: Lacquer is a fast-drying, durable finish that offers excellent protection. It’s available in gloss, semi-gloss, and satin finishes. Lacquer is often used on high-end furniture and cabinets due to its durability and clarity.

- Polyurethane: Polyurethane is a durable, water-resistant finish that provides excellent protection against scratches and abrasions. It’s available in gloss, semi-gloss, satin, and matte finishes. Polyurethane is a good choice for kitchen cabinets and other high-traffic areas.

- Oil: Oil finishes, such as tung oil or linseed oil, penetrate the wood’s surface and provide a natural, water-resistant finish. They are not as durable as other finishes but offer a unique, hand-rubbed look.

- Wax: Wax finishes are a natural, protective coating that enhances the wood’s natural beauty. They are not as durable as other finishes but are easy to apply and maintain.

- Paint:

- Advantages: Wide color selection, easy application, durable, washable.

- Disadvantages: Can hide the wood’s natural grain, requires multiple coats for good coverage.

- Stain:

- Advantages: Enhances the wood’s natural grain, offers a wide range of colors.

- Disadvantages: Less durable than paint, can be difficult to apply evenly, requires a topcoat for protection.

- Varnish:

- Advantages: Durable, water-resistant, enhances the wood’s natural beauty.

- Disadvantages: Can be difficult to apply without streaks or bubbles, requires multiple coats for good protection.

- Lacquer:

- Advantages: Fast-drying, durable, excellent protection, clear finish.

- Disadvantages: Can be difficult to apply without dust or imperfections, requires a spray booth for best results.

- Polyurethane:

- Advantages: Durable, water-resistant, protects against scratches and abrasions.

- Disadvantages: Can be difficult to apply without streaks or bubbles, requires multiple coats for good protection.

- Oil:

- Advantages: Penetrates the wood’s surface, provides a natural finish, easy to repair.

- Disadvantages: Not as durable as other finishes, requires frequent reapplication.

- Wax:

- Advantages: Natural, easy to apply and maintain, enhances the wood’s natural beauty.

- Disadvantages: Not as durable as other finishes, requires frequent reapplication.

- Preparation: Before applying any finish, it’s crucial to prepare the wood surface. This involves sanding the wood to a smooth finish, removing any dust or debris, and applying a wood conditioner if necessary.

- Application: The application method depends on the chosen finish. Paint can be applied with a brush, roller, or sprayer. Stains are typically applied with a brush or cloth. Varnish, lacquer, and polyurethane are often applied with a brush or sprayer.

- Drying Time: Allow sufficient drying time between coats, as recommended by the manufacturer.

- Topcoat: Most finishes require a topcoat for protection and durability.

- Work in a well-ventilated area. Some finishes release harmful fumes.

- Wear protective gear, including gloves, a mask, and eye protection.

- Use a quality brush or sprayer. A good brush or sprayer will help ensure a smooth, even finish.

- Apply thin, even coats. Avoid applying thick coats, as this can lead to runs or drips.

- Allow sufficient drying time between coats. This will help prevent the finish from becoming cloudy or uneven.

- Sand lightly between coats. This will help create a smooth, even finish.

- Apply a final coat of wax or sealant. This will help protect the finish and enhance its durability.

- Ancient Egypt: Ancient Egyptian cabinets were often made from cedarwood and decorated with hieroglyphs and religious motifs. These cabinets were used for storing precious items, clothing, and other valuables.

- Ancient Greece: Greek cabinets were characterized by their simple, geometric designs and often featured bronze handles and feet. These cabinets were used for storing household items and were typically made from wood or marble.

- Roman Empire: Roman cabinets were similar to Greek cabinets but often incorporated more elaborate carvings and decorations. They were used for storing a variety of items, including books, clothing, and jewelry.

- Medieval Period: Medieval cabinets were often made from oak and featured heavy, ornate designs. They were used for storing food, clothing, and other household items.

- Renaissance Period: The Renaissance saw a revival of classical design elements. Cabinets from this period were often made from walnut or cherry wood and featured intricate carvings and marquetry. They were used for storing books, manuscripts, and other valuables.

- Baroque Period: Baroque cabinets were characterized by their grand scale and elaborate ornamentation. They were often made from mahogany or walnut and featured gilded carvings, marble tops, and ornate hardware.

- Rococo Period: Rococo cabinets were more delicate and feminine than Baroque cabinets. They were often made from lighter woods, such as cherry or maple, and featured shell-like carvings and floral motifs.

- Victorian Era: Victorian cabinets were often made from dark woods, such as mahogany or walnut, and featured intricate carvings, elaborate hardware, and often included glass doors. They were used for storing a variety of items, including books, china, and silverware.

- Art Nouveau Period: Art Nouveau cabinets were characterized by their flowing, organic designs and often featured natural motifs, such as flowers and leaves. They were often made from exotic woods and featured metal hardware.

- Art Deco Period: Art Deco cabinets were characterized by their geometric designs and use of bold colors. They were often made from exotic woods and featured metal hardware.

- Mid-Century Modern Period: Mid-century modern cabinets were characterized by their clean lines, simple designs, and use of natural materials. They were often made from wood or metal and featured minimalist hardware.

- Online Resources: The internet offers a vast library of woodworking resources, including websites, blogs, and online communities dedicated to woodworking. Some popular platforms include:

- Woodworking for Mere Mortals: This website offers a wealth of free woodworking plans, tutorials, and articles covering a wide range of woodworking projects, including cabinets.

- Ana White: A well-known woodworking website featuring free woodworking plans for furniture, cabinets, and other projects, with detailed instructions and helpful tips.

- Popular Woodworking Magazine: This magazine provides in-depth articles, project plans, and woodworking tips for all skill levels, with a focus on building quality cabinets.

- Fine Woodworking Magazine: A renowned woodworking magazine featuring articles on woodworking techniques, design, and project plans, including intricate cabinet designs.

- Offline Resources: While online resources are abundant, offline resources offer a tangible learning experience and opportunities for hands-on guidance.

- Local Woodworking Stores: Many woodworking stores offer workshops, classes, and consultations with experienced woodworkers who can provide valuable insights and personalized guidance.

- Community Colleges and Vocational Schools: These institutions offer woodworking courses, certificates, and degrees, providing comprehensive training in woodworking techniques, including cabinet making.

- Woodworking Books: There are countless woodworking books available, covering various aspects of woodworking, from basic techniques to advanced cabinet making.

- Woodworking Blogs: Many woodworking blogs provide valuable insights, tips, and project ideas, with a focus on cabinet making. Some popular woodworking blogs include:

- The Wood Whisperer: A popular woodworking blog featuring tutorials, project plans, and woodworking tips from experienced woodworker Marc Spagnuolo.

- Shanty2Chic: A blog focusing on DIY projects, including furniture and cabinets, with step-by-step instructions and inspiring design ideas.

- Sawdust Girl: A blog run by a female woodworker, offering woodworking tutorials, project plans, and inspiring stories from the world of woodworking.

- Woodworking Forums: Woodworking forums provide a platform for discussions, questions, and advice among woodworking enthusiasts. Some popular woodworking forums include:

- The Woodworking Forum: A large online community dedicated to woodworking, offering discussions, advice, and project ideas.

- Lumberjocks: A woodworking community website where members share their projects, discuss woodworking techniques, and offer advice to each other.

- Woodworking Talk: A forum dedicated to woodworking, offering discussions on various topics, including cabinet making.

- Custom Cabinet Makers: These professionals specialize in crafting high-quality, custom cabinets, often using intricate designs and exquisite craftsmanship.

- Furniture Makers: Many furniture makers incorporate cabinets into their designs, showcasing unique styles and woodworking techniques.

- Woodworking Competitions: Competitions like the Woodworking Show and the International Woodworking Fair feature talented woodworkers showcasing their skills and innovative designs.

Construction Techniques for Woodworking Cabinets

Building a cabinet is a rewarding project that combines precision and creativity. This section will guide you through the essential construction techniques, from cutting and joining components to assembling the final product.

Cutting Cabinet Components

Cutting the cabinet components accurately is the foundation of a well-built cabinet. Properly sized pieces ensure that the cabinet assembles correctly and that the doors and drawers function smoothly.

Joining Cabinet Components

Once the cabinet components are cut, you need to join them securely to create a sturdy and durable cabinet. Various joining techniques are available, each with its own advantages and disadvantages.

Assembling the Cabinet

After cutting and joining the cabinet components, you are ready to assemble the cabinet.

Creating Cabinet Doors

Cabinet doors add a touch of style and functionality to your cabinet.

Creating Cabinet Drawers, Woodworking plans cabinets

Drawers provide a convenient way to store items in your cabinet.

Creating Cabinet Shelves

Shelves are essential for organizing items in your cabinet.

Finishing Techniques for Woodworking Cabinets

The final touch to your woodworking cabinet project is the finish. It not only enhances the appearance but also protects the wood from damage and wear. Choosing the right finish for your cabinets depends on factors like desired look, durability, and ease of application.

Types of Cabinet Finishes

The types of finishes available for woodworking cabinets are diverse, each offering unique properties.

Advantages and Disadvantages of Cabinet Finishes

Each finish has its pros and cons, influencing your choice.

Applying Cabinet Finishes

Applying a finish to your woodworking cabinets requires preparation and attention to detail.

Tips for Applying Finishes

Here are some helpful tips for applying finishes to woodworking cabinets:

Styles and Designs of Woodworking Cabinets

Woodworking cabinets are not just functional storage solutions; they are also design elements that can significantly impact the aesthetics of a room. Cabinet styles have evolved over time, influenced by historical periods, cultural trends, and technological advancements. Understanding these styles can help you choose the perfect cabinet for your needs and design preferences.

Historical Influences on Cabinet Design

Cabinet design has been shaped by various historical periods and cultural influences. For example, the Victorian era saw the rise of ornate cabinets with intricate carvings and elaborate details. In contrast, the mid-century modern movement emphasized simplicity, functionality, and clean lines.

Popular Woodworking Cabinet Styles

Different cabinet styles are characterized by distinct design features, such as the shape of the doors, the type of hardware, and the overall aesthetic.

| Style | Description | Example |

|---|---|---|

| Shaker | Simple, functional, and minimalist, featuring clean lines and unadorned surfaces. | Shaker kitchen cabinets with plain doors and simple hardware. |

| Mission | Inspired by Arts and Crafts movement, emphasizing craftsmanship and natural materials. Features robust construction and simple, geometric designs. | Mission-style bookcases with sturdy construction and exposed joinery. |

| Traditional | Classic and elegant, often featuring ornate details, decorative moldings, and traditional hardware. | Traditional china cabinets with intricate carvings and glass doors. |

| Contemporary | Modern and minimalist, featuring clean lines, simple designs, and often incorporating materials like metal and glass. | Contemporary bathroom cabinets with sleek lines and minimalist hardware. |

| Country | Rustic and charming, often featuring distressed finishes, natural wood textures, and simple hardware. | Country-style kitchen cabinets with distressed paint and simple hardware. |

Practical Applications of Woodworking Cabinets

Woodworking cabinets are a versatile and practical addition to any home. They offer a multitude of uses, from storing everyday essentials to showcasing treasured possessions. The design and functionality of these cabinets can be tailored to meet specific needs, making them an ideal solution for various rooms in the house.

Kitchen Cabinets

Kitchen cabinets are the heart of any kitchen, providing ample storage space for cookware, utensils, and food supplies. Design considerations for kitchen cabinets include maximizing storage capacity, optimizing workflow, and ensuring accessibility. For example, incorporating pull-out drawers, spice racks, and corner cabinets can enhance functionality and efficiency. Innovative designs like integrated appliances, hidden pantries, and open shelving add a modern touch while maximizing space utilization.

Bathroom Cabinets

Bathroom cabinets are essential for storing toiletries, towels, and other bathroom necessities. Design considerations for bathroom cabinets include maximizing storage space, creating a clean and organized look, and incorporating moisture-resistant materials. For example, vanity cabinets with integrated sinks, medicine cabinets with mirrored doors, and linen cabinets with pull-out shelves provide ample storage and a sleek aesthetic. Innovative designs include floating cabinets, mirrored storage units, and towel racks with integrated shelves.

Bedroom Cabinets

Bedroom cabinets are ideal for storing clothing, shoes, and other personal belongings. Design considerations for bedroom cabinets include maximizing storage space, creating a visually appealing look, and ensuring accessibility. For example, walk-in closets with custom shelving and drawers, armoires with built-in mirrors, and bedside cabinets with hidden storage compartments offer both functionality and style. Innovative designs include built-in wardrobes, modular storage systems, and under-bed storage solutions.

Living Room Cabinets

Living room cabinets are used for storing entertainment equipment, books, and decorative items. Design considerations for living room cabinets include creating a focal point, integrating seamlessly with the room’s decor, and providing ample storage space. For example, entertainment centers with built-in speakers, bookshelves with sliding doors, and display cabinets with glass shelves offer both functionality and aesthetic appeal. Innovative designs include floating cabinets, multi-functional units, and integrated lighting.

Office Cabinets

Office cabinets are essential for storing files, documents, and office supplies. Design considerations for office cabinets include maximizing storage capacity, creating a professional look, and ensuring accessibility. For example, filing cabinets with lockable drawers, lateral files with adjustable shelves, and desk cabinets with integrated organizers provide both functionality and security. Innovative designs include modular storage systems, mobile cabinets, and wall-mounted shelves.

Resources and Inspiration for Woodworking Cabinets

You’ve mastered the basics of woodworking cabinets, and now you’re ready to take your skills to the next level. To fuel your creativity and expand your knowledge, it’s essential to tap into the wealth of resources available online and offline. This section will guide you to reputable sources for woodworking cabinet plans, tutorials, and inspiration from skilled craftspeople.

Reputable Online and Offline Resources for Woodworking Cabinet Plans and Tutorials

Finding reliable sources for woodworking cabinet plans and tutorials is crucial for success. These resources provide detailed instructions, step-by-step guides, and valuable tips from experienced woodworkers.

Woodworking Blogs, Forums, and Communities

Connecting with a community of woodworking enthusiasts can provide inspiration, support, and valuable insights. These online platforms offer opportunities to share your projects, seek advice, and learn from experienced woodworkers.

Examples of Woodworking Cabinet Projects Created by Skilled Craftspeople

Observing the work of skilled craftspeople can inspire your own woodworking projects. Studying their techniques, design choices, and attention to detail can provide valuable insights and motivate you to elevate your woodworking skills.

Conclusion

With woodworking plans cabinets, you can unlock your creative potential and bring your storage dreams to life. From selecting the perfect wood species to mastering finishing techniques, each step offers an opportunity for personal expression and satisfaction. As you delve into the world of woodworking cabinets, remember that patience, precision, and a dash of creativity are your greatest allies. So, grab your tools, gather your materials, and let the journey of cabinet construction begin!

Common Queries

What are the most common wood species used for cabinets?

Popular choices include maple, cherry, oak, and walnut, each offering unique characteristics in terms of grain, color, and durability.

How do I choose the right woodworking plans for my project?

Consider the size, style, and complexity of the cabinet you want to build. Look for plans with detailed instructions, clear diagrams, and a list of required materials.

What are some essential woodworking tools for cabinet construction?

Basic tools include a saw, drill, sander, router, clamps, and measuring tools. You may also need specialized tools depending on the complexity of the project.

Where can I find inspiration for woodworking cabinet designs?

Explore online woodworking communities, magazines, and books for design ideas. You can also visit local woodworking shops and craft fairs for inspiration.

Woodworking plans for cabinets can range from simple nightstands to intricate kitchen cabinets. If you’re looking for a project with a bit more flair, you might want to check out lectern woodworking plans. These plans can teach you the basics of building a functional and stylish lectern, which can be a great addition to any home office or study.

Once you’ve mastered the techniques, you can apply them to your next cabinet project, whether it’s a bookshelf, a media console, or a custom piece of furniture.