Woodworking plans workbench – a phrase that conjures up images of sturdy, well-crafted workspaces, perfect for bringing your woodworking dreams to life. But where do you even begin? This guide will walk you through everything you need to know, from choosing the right plan to building a workbench that meets your specific needs. Whether you’re a seasoned woodworker or just starting out, you’ll find valuable insights and practical advice here.

Imagine having a workbench that’s not only functional but also a testament to your woodworking skills. That’s the power of woodworking plans. They provide detailed instructions, precise measurements, and helpful tips, making the process of building a workbench more manageable and enjoyable. From choosing the right materials to mastering essential techniques, you’ll gain confidence with every step of the journey.

Introduction to Workbenches

A sturdy workbench is an essential tool for any woodworker. It provides a stable and secure platform for cutting, shaping, and assembling your projects. A good workbench will make your woodworking experience more efficient, accurate, and enjoyable.

Types of Workbenches

There are many different types of workbenches available, each with its own unique features and benefits. Here are some of the most common types:

- Traditional Workbenches: These are the classic workbenches that have been used for centuries. They are typically made of heavy-duty wood and have a solid, stable construction. Traditional workbenches are often equipped with a vise, a bench dog system, and a tool tray. They are perfect for a wide range of woodworking tasks, from basic cutting to intricate joinery.

- Mobile Workbenches: These workbenches are designed to be portable and can be easily moved around the workshop. They are often made of lighter materials, such as metal or plastic, and may have wheels or casters for easy mobility. Mobile workbenches are a great option for those who have limited space or need to work on multiple projects in different locations.

- Specialized Workbenches: These workbenches are designed for specific woodworking tasks, such as carving, turning, or metalworking. They may have unique features, such as a tilting top, a built-in sanding station, or a specialized vise. Specialized workbenches are a good choice for woodworkers who focus on a particular type of work.

Key Features of a Well-Designed Workbench

A well-designed workbench should have several key features that make it both functional and comfortable to use. These features include:

- Sturdy Construction: The workbench should be made of durable materials and have a strong, rigid frame. This will ensure that it can withstand the weight of your tools and projects.

- Adequate Work Surface: The workbench should have a large enough work surface to accommodate your projects. Consider the size of the projects you typically work on and make sure the workbench is big enough to handle them comfortably.

- Proper Height: The workbench should be the right height for you. This will help you avoid back strain and fatigue. A good rule of thumb is to adjust the workbench so that your elbows are bent at a 90-degree angle when you are standing at the workbench.

- Vise: A vise is an essential tool for holding your workpieces securely in place. Choose a vise that is strong enough to hold your projects firmly and has a wide jaw opening to accommodate different sizes of wood.

- Bench Dogs: Bench dogs are metal pins that are inserted into holes in the workbench top. They can be used to hold your workpieces in place and to create a secure platform for planing and other operations.

- Tool Tray: A tool tray is a convenient place to store your tools and keep them organized. Look for a tray that is large enough to hold all of your essential tools and is easy to clean.

Woodworking Plans

Woodworking plans are essential tools for any woodworker, regardless of skill level. They provide a blueprint for your project, outlining the materials, dimensions, and assembly steps. Whether you’re a seasoned craftsman or just starting out, using woodworking plans offers numerous advantages.

Benefits of Using Woodworking Plans

Woodworking plans offer several benefits that make them valuable resources for any woodworker. They provide a clear and concise guide to your project, ensuring you have all the necessary information to complete it successfully.

- Reduced Errors: Woodworking plans minimize the risk of mistakes by providing detailed instructions and diagrams, helping you avoid costly errors and rework.

- Enhanced Accuracy: Detailed dimensions and cut lists in plans ensure precise measurements and cuts, resulting in a more accurate and professional-looking finished product.

- Time Efficiency: Plans help you plan your project effectively, saving you time by streamlining the process and eliminating guesswork.

- Improved Organization: Woodworking plans encourage a structured approach to your projects, ensuring you have all the necessary materials and tools on hand before you begin.

- Confidence Boost: Following plans can build confidence in your woodworking skills, especially for beginners. The step-by-step guidance provides a sense of accomplishment and encourages experimentation.

Types of Woodworking Plans

Woodworking plans are available in various formats and levels of complexity, catering to different skill levels and project needs.

- Free Plans: Numerous websites and online communities offer free woodworking plans, providing a great starting point for beginners and those seeking inspiration.

- Paid Plans: Paid plans often provide more detailed instructions, high-quality diagrams, and professional-level designs. These plans are ideal for complex projects or those seeking premium quality.

- Beginner Plans: Beginner plans are designed for those new to woodworking, offering simple projects with clear instructions and basic techniques.

- Advanced Plans: Advanced plans cater to experienced woodworkers, featuring complex designs, intricate joinery, and challenging techniques.

Resources for Finding Woodworking Plans

Finding high-quality woodworking plans is easy with numerous online and offline resources available. Here are some popular options:

- Online Woodworking Communities: Websites like Ana White, Woodworking for Mere Mortals, and The Wood Whisperer offer free and paid plans, along with tutorials and community forums.

- Woodworking Magazines: Popular magazines like Woodworking Magazine, Fine Woodworking, and Popular Woodworking provide plans, articles, and project ideas.

- Bookstores: Bookstores offer a wide selection of woodworking books containing plans for various projects, from furniture to home decor.

- Local Woodworking Clubs: Joining a local woodworking club provides access to experienced woodworkers, resources, and potentially shared plans.

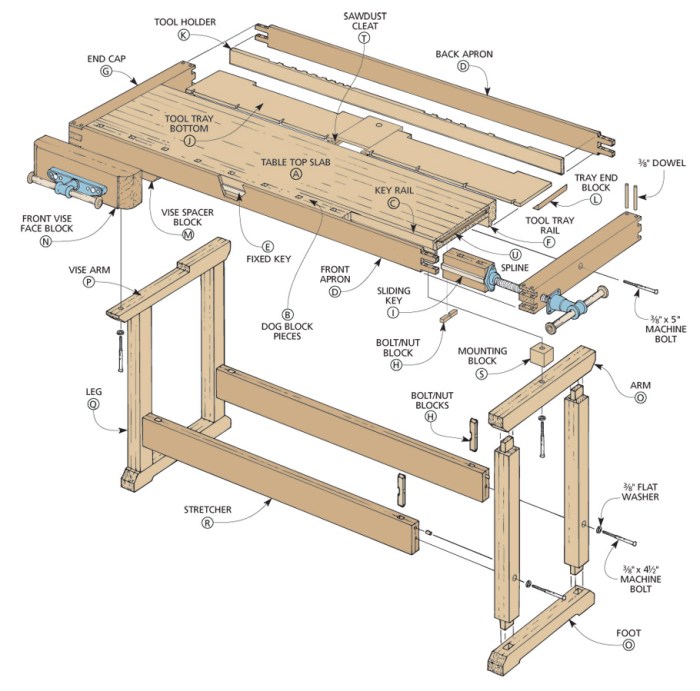

Essential Workbench Components

A workbench is more than just a flat surface; it’s the heart of your workshop. To build a workbench that meets your needs, you’ll need to understand the essential components and their functions. Let’s dive into the key elements that make a workbench both sturdy and versatile.

Workbench Components

| Component | Description | Function | Examples |

|---|---|---|---|

| Top | The flat surface where you work. Made of various materials like solid wood, plywood, or even epoxy resin. Thickness and design vary depending on intended use. | Provides a stable and durable surface for clamping, cutting, and assembling projects. |

|

| Legs | The support structure for the workbench top. Materials include wood, metal, or a combination of both. Shape and design influence stability and aesthetics. | Provide a strong and stable base for the workbench, ensuring it can withstand the weight of tools and materials. |

|

| Vices | Clamping devices used to secure workpieces for safe and accurate cutting, shaping, and assembly. Types include bench vises, tail vises, and quick-release vises. | Provide a secure hold on workpieces, allowing for precise cuts, drilling, and other operations. |

|

| Storage | Components designed to organize and store tools, materials, and supplies. Includes drawers, shelves, cabinets, and pegboards. | Keep your workshop organized and efficient, making tools and materials easily accessible. |

|

Building a Workbench from Plans

You’ve got your plans, you’ve gathered your materials, and you’re ready to build. Now, let’s dive into the steps of bringing your workbench to life.

Cutting and Preparing Materials

The first step is to cut all the wood to the dimensions specified in your plans. It’s important to use accurate measurements and sharp tools for precise cuts. Use a saw, such as a circular saw or a miter saw, to cut the wood. Be sure to double-check your measurements before making each cut.

After cutting, prepare the wood for assembly. This may involve sanding the edges, smoothing out any rough spots, and applying a finish to the wood.

Assembling the Frame

The frame is the foundation of your workbench. It’s important to build a sturdy frame that can support the weight of the top and your tools. The frame is usually made of sturdy lumber, like 2x4s or 4x4s.

You can use various joinery techniques to assemble the frame, such as mortise and tenon joints, pocket holes, or simple butt joints reinforced with glue and screws.

The type of joinery you choose will depend on your skill level and the complexity of your plans.

Installing the Top

The workbench top is the surface you’ll be working on. It’s essential to choose a material that’s durable and can withstand the wear and tear of woodworking. Popular choices include solid wood, plywood, or even laminated melamine.

To install the top, you’ll need to attach it to the frame securely. This can be done with screws, bolts, or clamps.

It’s important to make sure the top is level and securely attached to the frame.

Adding Vices and Storage

Vices and storage are essential features for any workbench. They provide a secure way to hold your workpieces and organize your tools. You can install vices on the sides or front of the workbench.

Vices can be purchased pre-made or built from scratch.

For storage, you can add drawers, shelves, or cabinets to your workbench. These can be built-in or purchased separately.

Finishing the Workbench

The final step is to finish the workbench. This may involve sanding the entire surface, applying a stain or paint, and sealing the wood.

The type of finish you choose will depend on the look you’re going for and the type of wood you used.

Workbenches for Specific Woodworking Tasks: Woodworking Plans Workbench

Workbenches are the backbone of any woodworking shop, providing a stable and versatile platform for various tasks. However, not all workbenches are created equal. Different woodworking tasks demand specific features and designs to optimize efficiency and accuracy. This section explores how workbench design can be tailored to specific woodworking tasks.

Workbench Designs for Specific Tasks

The design of a workbench can significantly impact its suitability for different woodworking tasks. Here’s a comparison of workbench designs for specific tasks:

| Task | Workbench Features | Examples |

|---|---|---|

| Hand Tool Work |

|

|

| Power Tool Use |

|

|

| Large-Scale Projects |

|

|

| Specialized Tasks |

|

|

Safety Considerations

Building and using a workbench involves inherent risks, so safety should be a top priority. By understanding and implementing proper safety practices, you can minimize the risk of injury and ensure a safe woodworking experience.

Safety Precautions When Building a Workbench

It’s essential to prioritize safety when building a workbench. Here are some important precautions to take:

- Wear safety glasses: Protect your eyes from flying debris and sawdust.

- Use hearing protection: Power tools can generate loud noise, which can damage your hearing over time.

- Use proper lifting techniques: Heavy objects, like workbench components, can cause strain and injury. Bend your knees, keep your back straight, and lift with your legs.

- Work in a well-ventilated area: Woodworking generates dust, which can be harmful to your lungs.

- Keep tools sharp: Dull tools require more force to use, increasing the risk of injury.

Safety Precautions When Using a Workbench

Using a workbench safely is just as important as building it safely. Here are some key precautions to consider:

- Keep the workbench clean and organized: A cluttered workbench can lead to accidents.

- Use the right tools for the job: Each tool has a specific purpose, and using the wrong tool can be dangerous.

- Use a clamp or vise to secure your work: This will prevent the workpiece from moving while you’re working on it.

- Be aware of your surroundings: Make sure there’s nothing in the way of your work area that could cause an accident.

- Don’t wear loose clothing or jewelry: These can get caught in moving machinery.

- Always disconnect power tools before making adjustments: This prevents accidental startup.

- Avoid using power tools while standing on a ladder or unstable surface: This significantly increases the risk of falls.

Avoiding Common Woodworking Hazards

Woodworking involves several common hazards that can be avoided with proper precautions. Here are some important points to remember:

- Dust: Woodworking generates dust, which can be harmful to your lungs. Wear a dust mask, use a dust collection system, and work in a well-ventilated area.

- Noise: Power tools can generate loud noise, which can damage your hearing over time. Wear hearing protection when using power tools.

- Flying debris: Woodworking can involve flying debris, such as wood chips and sawdust. Wear safety glasses to protect your eyes.

- Sharp tools: Woodworking tools are sharp and can cause serious injuries. Always use sharp tools, and handle them with care.

- Heavy objects: Woodworking often involves lifting and moving heavy objects. Use proper lifting techniques to avoid strain and injury.

- Power tools: Power tools can be dangerous if not used properly. Always read the manufacturer’s instructions before using a power tool, and use it with caution.

Importance of Using Proper Tools and Techniques

Using the right tools and techniques is crucial for both safety and efficiency in woodworking.

- Using the right tool for the job: Each tool is designed for a specific purpose, and using the wrong tool can be dangerous and inefficient.

- Proper tool maintenance: Regularly maintain your tools to ensure they are in good working order and safe to use.

- Learning proper techniques: Learning and practicing proper woodworking techniques can help you avoid injuries and produce better results.

Workbench Maintenance and Care

A well-maintained workbench is essential for any woodworking project. It ensures your workspace remains safe, efficient, and long-lasting. By implementing a regular maintenance routine, you can protect your investment and extend the life of your workbench.

Cleaning and Dust Removal, Woodworking plans workbench

Keeping your workbench clean is crucial for both safety and accuracy. Regular cleaning helps prevent dust and debris from accumulating, which can interfere with your work and potentially cause damage to your tools.

- Use a damp cloth to wipe down the workbench surface after each use, removing any sawdust, wood chips, or other debris.

- For more stubborn stains, a mild soap solution can be used. Avoid harsh chemicals or abrasive cleaners that could damage the finish.

- If your workbench has a vise, ensure to clean the jaws regularly to remove any metal shavings or debris.

Repairing Damage

Over time, your workbench may experience wear and tear, such as scratches, dents, or cracks. Promptly addressing these issues will help prevent further damage and maintain the integrity of the workbench.

- For minor scratches and dents, use wood filler or epoxy to repair the surface. Ensure the filler is compatible with the wood type of your workbench.

- For larger cracks or splits, consult a professional woodworker or carpenter to assess the damage and recommend the appropriate repair method.

Protecting the Workbench Surface

Protecting the workbench surface is essential to prevent scratches, stains, and other damage. Applying a sealant or finish can create a barrier that protects the wood and makes it easier to clean.

- Consider applying a layer of polyurethane or varnish to the workbench surface. These finishes offer protection against water, stains, and scratches.

- For workbenches with a natural wood finish, use a beeswax or oil-based sealant to nourish and protect the wood.

- If your workbench is exposed to direct sunlight, consider using a UV-resistant finish to prevent fading and damage.

Conclusion

Building a workbench from plans is a rewarding experience. You’ll gain valuable woodworking skills, create a custom workspace that suits your needs, and have a piece of furniture you can be proud of. Remember, it’s all about taking your time, following the plans carefully, and enjoying the process. With the right plan and a little dedication, you’ll be ready to tackle any woodworking project with confidence.

FAQ

What are the best woodworking plans for beginners?

There are many great beginner-friendly woodworking plans available online and in woodworking magazines. Look for plans that are well-illustrated, provide detailed instructions, and use common woodworking techniques.

How do I choose the right workbench plan?

Consider the size and type of woodworking projects you plan to do, the space you have available, and your budget. Look for plans that offer features that meet your specific needs.

What are the essential tools for building a workbench?

You’ll need basic woodworking tools like a saw, hammer, drill, screwdriver, measuring tape, and clamps. Depending on the plan, you may also need specialized tools like a router or a planer.

A sturdy workbench is essential for any woodworker, especially during the holiday season when you’re tackling those special projects. If you’re looking for inspiration, check out these holiday woodworking plans to find the perfect gift or decoration to make. Once you’ve got your plans, you can set up your workbench and get started creating something truly unique!