Custom woodworking projects set the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset.

From the initial spark of inspiration to the final sanding and finishing, custom woodworking is a journey of creativity, craftsmanship, and personal fulfillment. This guide will equip you with the knowledge and skills to transform your woodworking dreams into tangible masterpieces.

The Appeal of Custom Woodworking Projects

Custom woodworking projects hold a unique appeal that goes beyond mere functionality. They offer a blend of artistic expression, practical skill, and personal satisfaction that sets them apart from mass-produced items. The ability to transform raw materials into bespoke pieces tailored to individual needs and preferences is a source of immense fulfillment for many.

The Satisfaction of Creating Personalized Projects

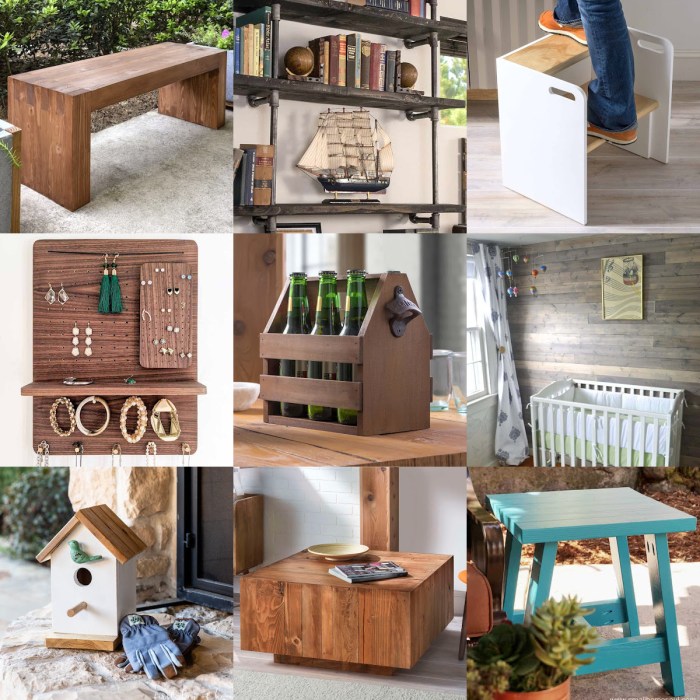

Custom woodworking projects allow individuals to express their creativity and personal style. Whether it’s a handcrafted table for a dining room, a unique bookshelf for a library, or a custom-designed toy for a child, each project becomes a reflection of the maker’s vision and skill. This personalized touch adds a layer of meaning and value that is unmatched by commercially produced items.

The Versatility of Custom Woodworking

Custom woodworking is a versatile craft with applications spanning diverse areas of life. It can be used to create functional furniture, decorative accents, architectural elements, and even intricate works of art. The possibilities are limited only by the imagination and skill of the woodworker.

Examples of Custom Woodworking Projects

- Furniture: Custom-made tables, chairs, desks, beds, and cabinets offer a unique blend of style, functionality, and durability.

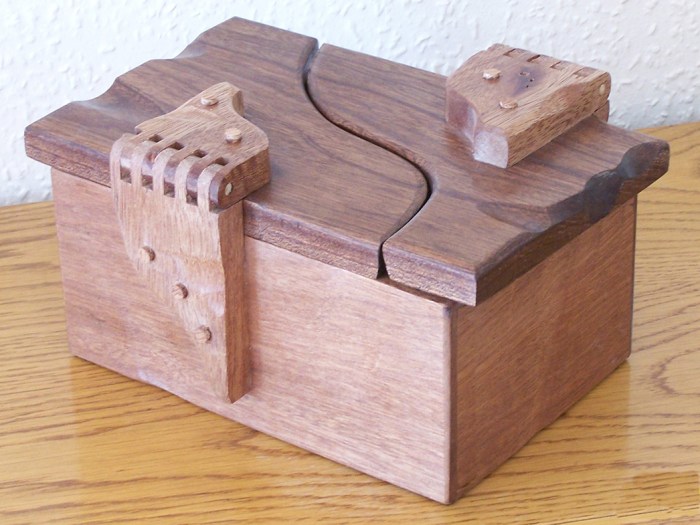

- Decorative Items: Wooden sculptures, carvings, picture frames, and decorative boxes add a touch of artistry and warmth to any space.

- Architectural Elements: Custom doors, windows, staircases, and moldings enhance the aesthetics and functionality of homes and buildings.

- Toys and Games: Handcrafted wooden toys, puzzles, and games provide children with engaging and educational experiences.

- Musical Instruments: Skilled woodworkers create custom guitars, violins, ukuleles, and other musical instruments that offer unique tones and craftsmanship.

Planning and Design

The planning and design phase of a custom woodworking project is crucial for success. It involves translating your vision into a detailed plan that guides the construction process. This phase requires careful consideration of design elements, materials, and functionality.

Creating Initial Sketches

Sketches are the first step in visualizing your project. They allow you to explore different design ideas and experiment with proportions, shapes, and features. You can use a pencil and paper, or a digital drawing program.

- Start with simple Artikels and basic shapes to establish the overall form of your project.

- Gradually add details, such as decorative elements, joinery, and hardware.

- Experiment with different angles and perspectives to get a comprehensive understanding of your design.

Developing 3D Models

3D modeling software can enhance your planning process by creating a virtual representation of your project. It allows you to visualize your design from all angles, identify potential problems, and refine details.

- Use software like SketchUp, Fusion 360, or SolidWorks to create 3D models.

- Start with a basic shape and gradually add details, using the software’s tools for creating curves, surfaces, and solids.

- Explore different materials and finishes within the software to see how they affect the final look and feel of your project.

Creating Detailed Plans

Detailed plans provide precise measurements and instructions for building your project. They are essential for accurate cutting, assembly, and finishing.

- Create detailed drawings that show all dimensions, angles, and joinery details.

- Use a drafting software or a CAD program for precise measurements and annotations.

- Label all parts clearly and provide a parts list with material specifications.

Designing a Custom Coffee Table

Let’s design a custom coffee table with a unique feature: a hidden compartment for storing remotes or magazines.

Dimensions and Features

- Overall dimensions: 48″ x 24″ x 18″ (length x width x height)

- Top: 1.5″ thick, made from walnut hardwood

- Legs: 1.5″ x 1.5″ square, made from maple hardwood

- Hidden compartment: 12″ x 12″ x 4″ (length x width x height), located under the top and accessed by a hidden hinge.

Materials

- Walnut hardwood (for top)

- Maple hardwood (for legs)

- Wood glue

- Wood screws

- Hidden hinge

- Wood finish (stain and polyurethane)

Essential Tools and Techniques: Custom Woodworking Projects

Custom woodworking demands a collection of tools that allow you to manipulate wood in various ways, from precise cuts to intricate shaping. This section will guide you through essential woodworking tools, categorizing them based on function, and delve into common techniques used in custom projects.

Essential Tools for Custom Woodworking

A comprehensive woodworking toolkit is essential for tackling custom projects. It’s crucial to have the right tools for each task, ensuring accuracy and efficiency. These tools can be categorized based on their function and purpose.

- Measuring and Marking Tools:

- Measuring Tape: Essential for measuring dimensions and marking lines on wood.

- Ruler: Used for precise measurements, especially for smaller pieces.

- Combination Square: Provides a ruler, protractor, and square in one tool, helpful for creating accurate angles and lines.

- Marking Gauge: A tool with a sliding head that allows you to mark parallel lines.

- Pencil: Used for marking lines on wood, ensuring accuracy.

- Cutting Tools:

- Hand Saw: Used for making straight cuts in wood, often employed for rough cuts or when power tools are not available.

- Circular Saw: A power tool with a rotating blade that makes quick and precise cuts.

- Table Saw: A stationary power tool with a rotating blade that cuts wood accurately, ideal for making precise cuts and ripping wood to length.

- Jigsaw: A power tool used for making curved cuts and intricate shapes.

- Router: A power tool with a spinning bit that shapes and trims wood, ideal for creating edges, grooves, and other details.

- Shaping Tools:

- Chisels: Used for carving, shaping, and removing wood.

- Planes: Hand tools used for smoothing and flattening wood surfaces.

- Sandpaper: Used to smooth surfaces, remove imperfections, and create a desired finish.

- Belt Sander: A power tool with a continuous belt of sandpaper, ideal for sanding large surfaces quickly and efficiently.

- Orbital Sander: A power tool with a rotating sanding pad, used for achieving a smooth finish on curved surfaces.

- Joining Tools:

- Clamps: Used to hold pieces of wood together while glue dries or during assembly.

- Screwdrivers: Used to drive screws into wood, securing pieces together.

- Drill: A power tool used to create holes in wood, allowing for the insertion of screws or dowels.

- Dowel Jig: A tool that creates precise holes for dowels, used for joining wood pieces securely.

- Glue Gun: Used for applying hot glue, a fast and efficient method for joining wood pieces.

- Finishing Tools:

- Paint Brushes: Used for applying paint, stain, or varnish to wood surfaces.

- Paint Roller: Used for applying paint or stain to large surfaces quickly and evenly.

- Spray Gun: Used for applying paint, stain, or varnish in a fine mist, ideal for achieving a smooth and even finish.

- Finishing Cloth: Used for applying wax or polish to wood surfaces, enhancing their appearance and providing protection.

- Sanding Block: Used for sanding wood surfaces by hand, achieving a smooth and even finish.

Common Woodworking Techniques

Custom woodworking projects require a variety of techniques to transform wood into functional and aesthetically pleasing pieces. Here are some common woodworking techniques:

- Cutting: Cutting is a fundamental technique in woodworking, used to shape and size wood pieces. It involves using saws, such as hand saws, circular saws, and table saws, to make precise cuts along straight or curved lines.

- Shaping: Shaping involves modifying the form of wood pieces to create specific contours or details. Techniques like planing, chiseling, and routing are used to create smooth surfaces, intricate curves, and decorative elements.

- Joining: Joining techniques are used to connect wood pieces together, creating a sturdy and stable structure. Common methods include gluing, screwing, doweling, and mortise and tenon joints. Each technique has its own advantages and disadvantages, and the choice depends on the project requirements and the desired level of strength and stability.

- Finishing: Finishing involves applying a protective layer to wood surfaces, enhancing their appearance and durability. Techniques include sanding, staining, painting, and applying wax or varnish. The type of finish depends on the desired aesthetic and the intended use of the finished product.

Woodworking Tools and Their Applications

| Tool | Application |

|---|---|

| Measuring Tape | Measuring dimensions, marking lines on wood |

| Ruler | Precise measurements, especially for smaller pieces |

| Combination Square | Creating accurate angles and lines |

| Marking Gauge | Marking parallel lines |

| Pencil | Marking lines on wood, ensuring accuracy |

| Hand Saw | Making straight cuts in wood, often employed for rough cuts or when power tools are not available |

| Circular Saw | Making quick and precise cuts |

| Table Saw | Making precise cuts and ripping wood to length |

| Jigsaw | Making curved cuts and intricate shapes |

| Router | Shaping and trimming wood, creating edges, grooves, and other details |

| Chisels | Carving, shaping, and removing wood |

| Planes | Smoothing and flattening wood surfaces |

| Sandpaper | Smoothing surfaces, removing imperfections, and creating a desired finish |

| Belt Sander | Sanding large surfaces quickly and efficiently |

| Orbital Sander | Achieving a smooth finish on curved surfaces |

| Clamps | Holding pieces of wood together while glue dries or during assembly |

| Screwdrivers | Driving screws into wood, securing pieces together |

| Drill | Creating holes in wood, allowing for the insertion of screws or dowels |

| Dowel Jig | Creating precise holes for dowels, used for joining wood pieces securely |

| Glue Gun | Applying hot glue, a fast and efficient method for joining wood pieces |

| Paint Brushes | Applying paint, stain, or varnish to wood surfaces |

| Paint Roller | Applying paint or stain to large surfaces quickly and evenly |

| Spray Gun | Applying paint, stain, or varnish in a fine mist, ideal for achieving a smooth and even finish |

| Finishing Cloth | Applying wax or polish to wood surfaces, enhancing their appearance and providing protection |

| Sanding Block | Sanding wood surfaces by hand, achieving a smooth and even finish |

Material Selection and Sourcing

Choosing the right wood is crucial for a successful custom woodworking project. Not only does it affect the final look and feel, but it also influences the project’s durability, workability, and even cost.

Types of Wood

Wood species offer a diverse range of properties, each with its unique characteristics. Here’s a breakdown of some common types:

- Hardwoods: Known for their strength, durability, and intricate grain patterns. They are generally more expensive than softwoods. Popular examples include oak, maple, cherry, walnut, and mahogany.

- Softwoods: Typically lighter, less expensive, and easier to work with than hardwoods. They are commonly used for construction and furniture projects. Popular examples include pine, spruce, fir, and cedar.

Selecting and Sourcing Materials

Selecting the right wood involves considering various factors:

- Budget: Different wood species have varying price points. Hardwoods are typically more expensive than softwoods. Consider your budget and choose wood that aligns with your financial constraints.

- Availability: Some wood species are more readily available than others, depending on your location. Check local lumberyards or online retailers to determine availability.

- Aesthetic Preferences: Wood grain patterns, colors, and textures play a significant role in the final look of your project. Choose wood that complements your desired aesthetic.

- Project Requirements: Consider the intended use of the project. For example, if you’re building a sturdy table, you’ll need a durable hardwood. If you’re making a decorative box, a softer wood might be more suitable.

Wood Species Comparison

| Wood Species | Grain Pattern | Durability | Suitability for Projects |

|---|---|---|---|

| Oak | Prominent, open grain with distinctive knots and swirls. | Very durable, resistant to wear and tear. | Tables, chairs, flooring, cabinets, boatbuilding. |

| Maple | Fine, even grain with a smooth, uniform appearance. | Hard, strong, and resistant to dents and scratches. | Furniture, countertops, cutting boards, musical instruments. |

| Cherry | Medium-sized pores with a rich, reddish-brown color that darkens with age. | Moderately durable, susceptible to scratches. | Furniture, cabinets, decorative items, wooden toys. |

| Walnut | Distinctive, bold grain with a rich, dark brown color. | Strong, durable, and resistant to moisture. | Furniture, gunstocks, veneers, high-end cabinetry. |

| Mahogany | Interlocked grain with a reddish-brown color that varies depending on the species. | Strong, durable, and resistant to moisture. | Fine furniture, boats, musical instruments, veneers. |

| Pine | Straight, soft grain with a yellowish color. | Soft and lightweight, susceptible to dents and scratches. | Construction, framing, furniture, crafts. |

| Spruce | Straight, fine grain with a light, yellowish color. | Lightweight and easy to work with. | Construction, framing, musical instruments, crafts. |

| Fir | Straight, coarse grain with a light, yellowish color. | Strong and durable, resistant to moisture. | Construction, framing, furniture, outdoor structures. |

| Cedar | Straight, even grain with a reddish-brown color. | Durable, resistant to decay and insects. | Outdoor structures, siding, furniture, crafts. |

End of Discussion

As you delve deeper into the world of custom woodworking, remember that the true beauty lies in the process. Each project, from intricate furniture to simple decorative pieces, is a testament to your dedication and skill. Embrace the challenge, celebrate the victories, and let your woodworking journey be a source of endless joy and satisfaction.

Question Bank

What are the best wood species for beginners?

Softwoods like pine and cedar are beginner-friendly due to their affordability and ease of working. They’re forgiving for mistakes and offer a good starting point for learning woodworking techniques.

How do I choose the right tools for my project?

Consider the specific tasks required for your project. Start with basic hand tools like a saw, hammer, and screwdriver. As your skills progress, you can gradually add specialized tools like a router, planer, and jointer.

What safety precautions should I take when woodworking?

Always wear safety glasses, hearing protection, and a dust mask. Use proper lifting techniques and avoid loose clothing or jewelry. Follow the manufacturer’s instructions for all tools and machinery.

Custom woodworking projects can be as simple or as complex as you want them to be. If you’re looking for a project that’s both functional and stylish, consider building a bookshelf. You can find a wide variety of bookshelf woodworking plans online, so you’re sure to find one that fits your needs and skill level.

Once you’ve got your plan, you can customize it to your heart’s content, adding personal touches that make it truly your own.