Ever wondered how those iconic buildings stand tall, defying gravity and time? From the ancient pyramids to modern skyscrapers, the secret lies in the craft of masonry and concrete. This guide takes you on a journey through the world of bricks, stone, tile, and stucco, revealing the techniques and secrets passed down through generations of master builders.

Get ready to learn how to build structures that are not only strong and durable but also aesthetically pleasing and energy-efficient.

This comprehensive guide will explore the history and evolution of these construction techniques, dive deep into the properties of different materials, and equip you with the knowledge to tackle your own projects. We’ll cover everything from laying bricks like a pro to creating stunning concrete foundations, walls, and slabs.

Whether you’re a seasoned builder or a curious beginner, this guide will empower you to unleash your inner construction master.

Foundations of Masonry & Concrete

The foundation of any structure, be it a humble dwelling or a towering skyscraper, is the cornerstone of its stability and longevity. For centuries, the art of masonry and concrete construction has played a pivotal role in shaping the built environment, from ancient pyramids to modern marvels of engineering.

Understanding the history, properties, and techniques associated with these materials is crucial for any aspiring builder or homeowner.

The Evolution of Masonry & Concrete

The history of masonry and concrete is intertwined with the development of human civilization. The earliest known examples of masonry construction date back to the Neolithic period, with structures like the megalithic tombs of Europe and the pyramids of Egypt.

These early builders relied on natural materials like stone, brick, and mud to create durable and impressive structures. The invention of concrete, a composite material made from cement, aggregates, and water, revolutionized construction. The Romans, known for their engineering prowess, perfected the use of concrete, employing it in the construction of aqueducts, roads, and monumental buildings like the Pantheon.

Over the centuries, advancements in concrete technology, including the development of Portland cement and reinforced concrete, have enabled the construction of increasingly complex and ambitious structures.

Properties of Concrete

Concrete is a versatile material with a wide range of applications in construction. Its properties, including its strength, durability, and moldability, make it an ideal choice for foundations, walls, floors, and other structural elements.

- Strength:Concrete’s strength is determined by its compressive strength, which is the amount of pressure it can withstand before failing. The compressive strength of concrete is measured in pounds per square inch (psi) and can vary depending on the type of cement used, the mix proportions, and the curing conditions.

You know, building a solid foundation is like taking care of your mental health. It’s all about laying down the groundwork for something strong and lasting. And just like Bloom Coloring book for Adults Beautiful Coolest Flowers Garden and Botanical Florals Prints for Stress & Anxiety Relief The Great Gift of Seniors …

Plants Nature and Gardening to Color helps you chill out and find your zen, “The Craft Of Masonry & Concrete A Comprehensive Guide to Building Durable Structures and Foundations with Concrete Brick Stone Tile & Stucco Techniques & Secrets from Master Builders” will teach you the skills to create a solid, stress-free structure that will stand the test of time.

Concrete with higher compressive strength is typically used for structural applications, while concrete with lower compressive strength may be suitable for non-structural elements.

- Durability:Concrete is known for its durability, resisting weathering, abrasion, and chemical attack. However, its durability can be affected by factors such as exposure to moisture, freeze-thaw cycles, and the presence of aggressive chemicals. Proper design, construction, and maintenance practices are crucial for ensuring the long-term durability of concrete structures.

- Moldability:Concrete is a highly moldable material, allowing it to be cast into a wide variety of shapes and sizes. This property makes it suitable for creating complex architectural elements, such as curved walls, columns, and beams.

Types of Concrete

The type of concrete used in a construction project depends on the specific requirements of the application. Here are some common types of concrete:

- Normal-weight concrete:This is the most common type of concrete, used for a wide range of applications. It has a density of approximately 145 pounds per cubic foot.

- Lightweight concrete:This type of concrete uses lightweight aggregates, such as expanded clay or shale, to reduce its weight. It is often used in applications where weight is a concern, such as roof decks and precast panels.

- High-strength concrete:This type of concrete uses a higher proportion of cement to achieve a higher compressive strength. It is often used in structural applications where high strength is required, such as bridges and high-rise buildings.

- High-performance concrete:This type of concrete has enhanced properties, such as improved durability, strength, and workability. It is often used in specialized applications, such as marine structures and underground tunnels.

Masonry Materials

Masonry materials are used to construct walls, floors, and other structural elements. They offer a range of benefits, including durability, aesthetic appeal, and energy efficiency.

- Brick:Brick is a versatile and durable masonry material that is commonly used for building walls, chimneys, and other structures. Bricks are made from clay or shale that is molded into blocks and then fired in a kiln. The color and texture of bricks can vary depending on the type of clay used and the firing process.

Brick is known for its strength, durability, and fire resistance. It can be used in a variety of architectural styles, from traditional to modern.

- Stone:Stone is a natural material that has been used for construction for centuries. It is known for its durability, beauty, and strength. Stone can be used in a variety of applications, including building walls, foundations, and landscaping. Common types of stone used in construction include granite, limestone, marble, and sandstone.

- Tile:Tile is a thin, flat material that is used for flooring, walls, and roofs. It is made from a variety of materials, including clay, ceramic, porcelain, and natural stone. Tile is known for its durability, water resistance, and aesthetic appeal.

It comes in a wide range of colors, patterns, and textures, making it a popular choice for both residential and commercial projects.

- Stucco:Stucco is a plaster-like material that is applied to exterior walls to create a smooth, decorative finish. It is made from a mixture of cement, sand, and water. Stucco is known for its durability, weather resistance, and fire resistance. It is often used in warm climates, as it can help to regulate the temperature inside a building.

Choosing the Right Materials

The choice of masonry materials for a particular project depends on several factors, including the intended use of the structure, the budget, and the desired aesthetic.

- Durability:For structures that will be exposed to harsh weather conditions, durable materials like brick or stone are often preferred. For interior applications, where durability is less of a concern, tile or stucco may be more suitable.

- Cost:Brick and stone are generally more expensive than tile or stucco. However, they can also be more durable and require less maintenance over the long term.

- Aesthetics:The desired aesthetic is also an important consideration. Brick and stone offer a classic and timeless look, while tile and stucco can provide a more modern or contemporary feel.

Building with Masonry & Concrete

Building with masonry and concrete involves various techniques and practices that are crucial for creating durable and long-lasting structures. This section delves into the intricate details of working with these materials, encompassing everything from laying bricks to constructing concrete foundations, walls, and slabs.

It also covers the art of working with stone, tile, and stucco, emphasizing their installation procedures, finishing techniques, and considerations for different architectural styles.

Laying Bricks

Laying bricks is a fundamental skill in masonry, requiring precision, attention to detail, and a keen understanding of mortar application. Bricklaying involves several key steps, including:

- Preparing the foundation: A solid and level foundation is essential for a stable brick structure. The foundation must be properly compacted and leveled to ensure the bricks are laid evenly.

- Laying the first course: The first course of bricks is crucial as it sets the foundation for the entire structure. The bricks should be laid precisely, ensuring a level and straight line. This often involves using a string line or a level to guide the placement of the bricks.

- Applying mortar: Mortar is used to bind the bricks together and create a strong bond. The consistency of the mortar is crucial for proper adhesion and workability. Too much water can make the mortar weak, while too little can make it difficult to spread.

The mortar should be applied evenly between the bricks, ensuring a consistent thickness.

- Jointing: Jointing is the process of shaping and smoothing the mortar joints between the bricks. This can be done using a variety of tools, such as a pointing trowel or a jointing tool. Proper jointing not only improves the aesthetics of the brickwork but also contributes to its durability and water resistance.

- Creating patterns: Bricks can be laid in various patterns, each adding a unique aesthetic to the structure. Common patterns include running bond, stacked bond, English bond, and Flemish bond. The choice of pattern depends on the desired aesthetic and the structural requirements.

Building a solid foundation takes serious skill, and “The Craft Of Masonry & Concrete” is your go-to guide for mastering the techniques. But hey, even master builders need to unwind, and that’s where “Cute Fairies Coloring Book For Adults And Teens 50 Beautiful Flower Fairies Illustrations for Relaxation and Stress Relief…Gift For Adults Teens Girls.Paperback – February 16 2023” comes in.

Cute Fairies Coloring Book For Adults And Teens 50 Beautiful Flower Fairies Illustrations for Relaxation and Stress Relief…Gift For Adults Teens Girls.Paperback – February 16 2023 Once you’ve got those walls up, you can channel your inner artist and chill out with some whimsical fairy coloring.

Then, back to the grind with “The Craft Of Masonry & Concrete”!

- Ensuring proper curing: Once the brickwork is complete, it’s essential to allow the mortar to cure properly. This typically involves keeping the brickwork moist for several days to allow the mortar to reach its full strength. Proper curing is crucial for the long-term durability of the brick structure.

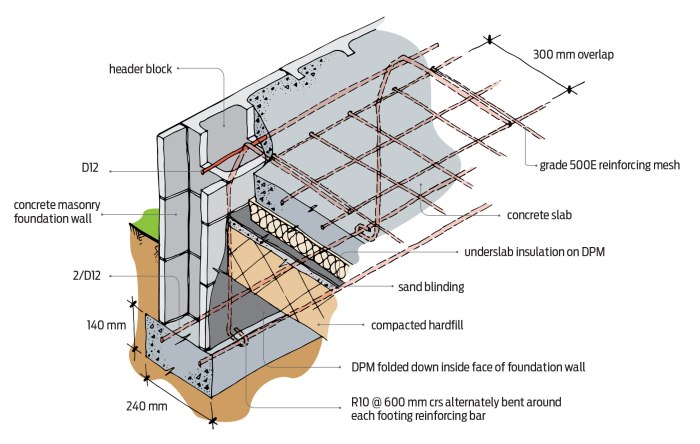

Constructing Concrete Foundations

Concrete foundations are the backbone of most structures, providing a solid and stable base for the entire building. The construction of concrete foundations involves several key steps:

- Excavation: The first step involves excavating the site to the required depth and width. The excavation should be done carefully to ensure a level and stable base for the foundation.

- Formwork: Formwork is used to create the shape and dimensions of the concrete foundation. It is typically made of wood, metal, or plastic, and is assembled to create a mold for the concrete to be poured into. The formwork must be strong enough to withstand the weight of the wet concrete and must be properly braced to prevent warping or collapsing.

- Reinforcement: Reinforcement is used to strengthen the concrete and increase its resistance to cracking and bending. Steel bars or mesh are commonly used for reinforcement, and they are placed within the formwork before the concrete is poured. The reinforcement should be properly spaced and tied together to ensure a strong and stable foundation.

- Pouring concrete: Once the formwork and reinforcement are in place, the concrete is poured into the mold. The concrete should be poured in layers and compacted to remove air bubbles and ensure a solid foundation. Proper compaction is essential for the strength and durability of the concrete.

- Curing: After the concrete is poured, it needs to be cured properly to allow it to reach its full strength. Curing involves keeping the concrete moist for a specific period, typically several days, to prevent it from drying out too quickly.

This can be done by covering the concrete with plastic sheeting or by spraying it with water regularly.

Constructing Concrete Walls

Concrete walls are a common structural element in various buildings, offering durability and fire resistance. The construction of concrete walls involves several key steps:

- Formwork: Similar to foundations, formwork is used to create the shape and dimensions of the concrete wall. The formwork is typically made of wood, metal, or plastic and is assembled to create a mold for the concrete to be poured into.

Yo, wanna build something epic? Like, a house that’ll stand the test of time? “The Craft Of Masonry & Concrete” is your guide to building durable structures, from foundations to finishes. It’s got all the secrets from master builders, and you can Download And Listen Here to learn how to lay brick, work with concrete, and even master stucco.

So ditch the flimsy DIY projects and get ready to build something truly badass.

The formwork must be strong enough to withstand the weight of the wet concrete and must be properly braced to prevent warping or collapsing.

- Reinforcement: Steel bars or mesh are used to reinforce the concrete wall, increasing its strength and resistance to cracking. The reinforcement is placed within the formwork before the concrete is poured, ensuring it is properly spaced and tied together.

- Pouring concrete: Once the formwork and reinforcement are in place, the concrete is poured into the mold. The concrete should be poured in layers and compacted to remove air bubbles and ensure a solid wall. Proper compaction is essential for the strength and durability of the concrete.

You know, sometimes you just gotta chill out and unleash your inner artist. Building durable structures with concrete and brick is serious business, but who says you can’t find some zen in it? Maybe you’re feeling the need for a little creative escape, like coloring in some badass ninjas and samurai from the Anime Coloring Book Ninja and Samurai Edition (Anime Coloring Books).

Then you can come back to your masonry project with a fresh perspective, ready to tackle those foundations like a true master builder.

- Curing: After the concrete is poured, it needs to be cured properly to allow it to reach its full strength. Curing involves keeping the concrete moist for a specific period, typically several days, to prevent it from drying out too quickly.

This can be done by covering the concrete with plastic sheeting or by spraying it with water regularly.

Constructing Concrete Slabs

Concrete slabs are commonly used for floors, patios, driveways, and other flat surfaces. The construction of concrete slabs involves several key steps:

- Preparing the subgrade: The subgrade is the soil or base beneath the concrete slab. It must be properly compacted and leveled to ensure a stable and even surface for the slab. The subgrade may require grading or adding a layer of gravel for proper drainage and support.

- Vapor barrier: A vapor barrier is a layer of plastic sheeting placed over the subgrade to prevent moisture from rising up from the soil and damaging the concrete slab. The vapor barrier should be properly overlapped and sealed to prevent moisture from penetrating.

- Reinforcement: Steel bars or mesh are used to reinforce the concrete slab, increasing its strength and resistance to cracking. The reinforcement is placed on top of the vapor barrier and is typically spaced and tied together to create a strong and stable grid.

- Pouring concrete: Once the reinforcement is in place, the concrete is poured over the vapor barrier and reinforcement. The concrete should be poured in layers and compacted to remove air bubbles and ensure a solid slab. Proper compaction is essential for the strength and durability of the concrete.

- Curing: After the concrete is poured, it needs to be cured properly to allow it to reach its full strength. Curing involves keeping the concrete moist for a specific period, typically several days, to prevent it from drying out too quickly.

This can be done by covering the concrete with plastic sheeting or by spraying it with water regularly.

Working with Stone

Stone is a natural material that adds beauty and durability to various architectural structures. Working with stone requires specialized techniques and tools. Stone installation involves several key steps:

- Preparing the surface: The surface where the stone will be installed must be properly prepared to ensure a level and stable base. This may involve cleaning the surface, applying a bonding agent, or adding a layer of mortar.

- Cutting and shaping: Stone may need to be cut and shaped to fit specific dimensions and designs. This can be done using specialized tools, such as diamond saws, grinders, and chisels.

- Installation: Stone is typically installed using mortar or adhesive, depending on the type of stone and the application. The stone is carefully placed and aligned, ensuring proper spacing and leveling.

- Grouting: After the stone is installed, the gaps between the stones are filled with grout, a mixture of cement, sand, and water. The grout is applied and smoothed to create a uniform and aesthetically pleasing finish.

- Sealing: Sealing the stone is essential for protecting it from moisture, stains, and weathering. Sealers are applied to the surface of the stone to create a protective barrier. The type of sealer used depends on the type of stone and the desired level of protection.

Working with Tile

Tile is a versatile material that can be used for floors, walls, backsplashes, and other surfaces. Working with tile requires precision, attention to detail, and proper installation techniques.Tile installation involves several key steps:

- Preparing the surface: The surface where the tile will be installed must be properly prepared to ensure a level and stable base. This may involve cleaning the surface, applying a bonding agent, or adding a layer of mortar.

- Laying out the tile: Before installing the tile, it is essential to lay out the tiles on the surface to determine the best layout and spacing. This helps to ensure that the tile is installed evenly and aesthetically pleasing.

- Installing the tile: Tile is typically installed using mortar or adhesive, depending on the type of tile and the application. The tile is carefully placed and aligned, ensuring proper spacing and leveling.

- Grouting: After the tile is installed, the gaps between the tiles are filled with grout, a mixture of cement, sand, and water. The grout is applied and smoothed to create a uniform and aesthetically pleasing finish.

- Sealing: Sealing the tile is essential for protecting it from moisture, stains, and weathering. Sealers are applied to the surface of the tile to create a protective barrier. The type of sealer used depends on the type of tile and the desired level of protection.

Working with Stucco

Stucco is a plaster-like material that is used for exterior and interior walls. It offers a durable and aesthetically pleasing finish. Working with stucco requires specialized techniques and tools.Stucco installation involves several key steps:

- Preparing the surface: The surface where the stucco will be applied must be properly prepared to ensure a level and stable base. This may involve cleaning the surface, applying a bonding agent, or adding a layer of wire mesh.

- Applying the base coat: The base coat is the first layer of stucco that is applied to the surface. It is typically a mixture of cement, sand, and water. The base coat should be applied evenly and allowed to dry completely before applying the next layer.

- Applying the brown coat: The brown coat is the second layer of stucco that is applied over the base coat. It is typically a thinner layer than the base coat and is used to create a smooth and even surface for the finish coat.

- Applying the finish coat: The finish coat is the final layer of stucco that is applied over the brown coat. It is typically a thin layer of stucco that is used to create the desired texture and finish. There are various finish techniques, such as smooth, textured, or rustic.

- Curing: After the stucco is applied, it needs to be cured properly to allow it to reach its full strength. Curing involves keeping the stucco moist for a specific period, typically several days, to prevent it from drying out too quickly.

This can be done by covering the stucco with plastic sheeting or by spraying it with water regularly.

Mastering the Craft

Welcome to the exciting world of masonry and concrete construction! This section dives deep into the practical knowledge and insider secrets that separate the novice from the master builder. We’ll unravel the common pitfalls that trip up beginners, arm you with the essential tools of the trade, and share the wisdom of seasoned pros to help you build structures that are not only durable but also visually stunning and energy-efficient.

So, get ready to elevate your skills and transform your building projects into masterpieces!

Common Mistakes and Solutions

Novice masons and concrete workers often encounter challenges that can hinder their progress and compromise the quality of their work. Understanding these common pitfalls and implementing preventative measures can save you time, money, and headaches.

- Inadequate Preparation:A solid foundation is essential for any structure, and neglecting proper preparation can lead to costly repairs down the line. Ensure the foundation is level, compacted, and free of debris.

- Incorrect Mortar Mix:The right mortar mix is crucial for achieving the desired strength, workability, and bonding properties. Consult with a building professional or consult a reputable mortar mix chart to determine the optimal ratio of cement, sand, and water for your specific project.

- Insufficient Curing:Concrete needs time to cure properly, developing its full strength and durability. Avoid premature traffic on newly poured concrete, and ensure adequate moisture retention during the curing process.

- Improper Tool Usage:Using the right tools and techniques is paramount to achieving accurate and efficient results. Invest in quality tools and familiarize yourself with their proper operation.

- Neglecting Safety Precautions:Masonry and concrete work involve potential hazards, including dust, fumes, and heavy lifting. Always prioritize safety by wearing appropriate personal protective equipment (PPE) and adhering to safe work practices.

Essential Tools and Equipment

Having the right tools at your disposal is crucial for efficient and effective masonry and concrete construction. Here’s a rundown of essential equipment, along with their specific functions:

- Masonry Trowel:This versatile tool is used for spreading mortar, shaping bricks, and smoothing joints. It’s a must-have for any masonry project.

- Brick Hammer:A brick hammer is used for breaking bricks and stones, shaping them for specific applications, and removing excess mortar.

- Level:A level ensures that horizontal and vertical surfaces are straight and true, crucial for maintaining structural integrity.

- Line Level:A line level is used to establish straight lines for brick courses, ensuring uniform alignment and visual appeal.

- Concrete Mixer:A concrete mixer ensures that the ingredients are thoroughly blended, resulting in a consistent and high-quality concrete mix.

- Wheelbarrow:A wheelbarrow is indispensable for transporting concrete, mortar, and other materials around the worksite.

- Shovel:A shovel is used for loading and unloading materials, as well as for mixing concrete and mortar.

- Safety Glasses:Protecting your eyes from flying debris is crucial, so always wear safety glasses when working with masonry and concrete.

- Work Gloves:Gloves protect your hands from cuts, abrasions, and chemical irritants.

Expert Tips and Tricks

Master builders have honed their skills over years of experience, accumulating a wealth of knowledge and practical techniques. Here are some expert tips to elevate your masonry and concrete construction:

- Pre-Soak Bricks:Before laying bricks, soak them in water for several hours. This helps prevent the bricks from absorbing moisture from the mortar, ensuring a strong bond.

- Use a Mortar Board:A mortar board is a flat surface used to mix and prepare mortar. This allows you to create a consistent mix and prevent waste.

- Proper Joint Spacing:Maintaining consistent joint spacing is crucial for structural stability and aesthetic appeal. Use a joint tool or a string line to guide you.

- Create a Smooth Finish:For a professional-looking finish, use a trowel to smooth out the mortar joints, creating a clean and consistent appearance.

- Proper Curing:Concrete needs to cure properly to achieve its full strength and durability. Keep the concrete moist during the curing process, using a plastic sheet or a curing compound.

- Energy-Efficient Design:Incorporate energy-efficient design elements, such as insulation and shading, to reduce energy consumption and create a more sustainable structure.

Final Wrap-Up

So, are you ready to embrace the art of building? With the right knowledge, tools, and a little bit of grit, you can create structures that will stand the test of time. Remember, it’s not just about laying bricks or pouring concrete; it’s about understanding the principles behind the craft and using your skills to bring your visions to life.

This guide is your blueprint for success, guiding you on a path to becoming a true master of masonry and concrete. Now, grab your tools, let’s get building!

User Queries

What are the most common mistakes made by novice masons and concrete workers?

Novice masons and concrete workers often make mistakes like improper mortar mixing, inconsistent brick placement, inadequate curing, and neglecting reinforcement. These errors can lead to structural weaknesses, uneven surfaces, and even cracking.

What are the essential tools and equipment needed for masonry and concrete construction?

Essential tools include trowels, chisels, hammers, levels, plumb bobs, measuring tapes, mixing tools, and forms for concrete work. The specific equipment needed will depend on the project’s scope and complexity.

What are some expert tips for achieving durable and aesthetically pleasing structures?

Expert tips include using high-quality materials, paying attention to detail, using proper techniques, and understanding the importance of curing and maintenance. Consider using techniques like dry-stacking for a rustic look or incorporating decorative elements like tile accents.