PVC furniture plans offer a fantastic opportunity to create durable, weather-resistant, and affordable furniture for your home or outdoor spaces. From simple shelves to intricate chairs, the possibilities are endless. With PVC’s versatility and ease of use, you can bring your furniture visions to life without breaking the bank.

This guide will walk you through the basics of PVC furniture construction, from selecting the right plan to assembling and finishing your project. We’ll cover everything from essential tools and materials to design considerations and safety precautions. So, whether you’re a seasoned DIY enthusiast or a beginner looking to tackle a new challenge, this guide has something for you.

Introduction to PVC Furniture

PVC furniture is a popular choice for both indoor and outdoor use due to its many benefits. This type of furniture is known for its durability, weather resistance, and affordability.

Benefits of PVC Furniture

PVC furniture offers a range of advantages that make it a desirable choice for various settings.

- Durability: PVC is a strong and rigid material that can withstand heavy use and resist wear and tear. It is less likely to crack, chip, or break compared to other materials like wood or metal.

- Weather Resistance: PVC is highly resistant to moisture, UV rays, and extreme temperatures. This makes it an ideal choice for outdoor furniture, as it can withstand harsh weather conditions without degrading.

- Affordability: PVC is a relatively inexpensive material, making PVC furniture more budget-friendly than furniture made from other materials. This affordability makes it accessible to a wider range of consumers.

- Easy Maintenance: PVC furniture is easy to clean and maintain. It can be wiped down with a damp cloth and requires minimal upkeep. This low-maintenance nature makes it a practical choice for busy households.

Common PVC Furniture Pieces

PVC furniture is versatile and can be used to create a variety of pieces.

- Chairs: PVC chairs are common in both indoor and outdoor settings. They are lightweight, durable, and easy to stack for storage.

- Tables: PVC tables are also popular choices for both indoor and outdoor use. They are sturdy and can withstand the weight of food and drinks. PVC tables are often used in dining areas, patios, and gardens.

- Lounges: PVC lounges offer a comfortable and relaxing seating option. They are often used in poolside areas, backyards, and balconies.

- Outdoor Furniture Sets: PVC is commonly used to create complete outdoor furniture sets, including chairs, tables, and lounges. These sets offer a cohesive and stylish look for outdoor spaces.

Types of PVC Furniture Plans

The internet offers a vast collection of PVC furniture plans, each catering to different skill levels and intended uses. This variety ensures that everyone, from beginners to experienced DIY enthusiasts, can find plans suitable for their needs.

Categorization of PVC Furniture Plans

The wide range of PVC furniture plans can be categorized based on their complexity, skill level, and intended use.

Complexity

- Simple Plans: These plans involve basic PVC pipe cutting and joining techniques, suitable for beginners. Examples include simple shelves, small tables, and basic chairs.

- Intermediate Plans: These plans require more intricate cutting and joining techniques, including the use of PVC fittings like elbows and tees. They often involve multiple components and require more precise measurements. Examples include more complex chairs, larger tables, and basic storage units.

- Advanced Plans: These plans demand advanced PVC fabrication skills, often involving custom-made components, intricate designs, and multiple assembly steps. Examples include modular furniture, furniture with complex shapes, and custom-designed pieces.

Skill Level

- Beginner: These plans are designed for individuals with little to no experience in PVC fabrication. They typically involve straightforward instructions and simple designs.

- Intermediate: These plans are suitable for individuals with some experience in PVC fabrication. They may involve more complex designs and require a greater understanding of PVC pipe cutting and joining techniques.

- Advanced: These plans are intended for experienced DIY enthusiasts with a deep understanding of PVC fabrication techniques. They may involve intricate designs, custom-made components, and complex assembly processes.

Intended Use

- Outdoor Furniture: These plans are designed for furniture that will be used outdoors, often featuring weather-resistant materials and construction techniques.

- Indoor Furniture: These plans are designed for furniture that will be used indoors, often focusing on aesthetics and functionality.

- Storage Solutions: These plans are designed for furniture that provides storage solutions, such as shelves, racks, and cabinets.

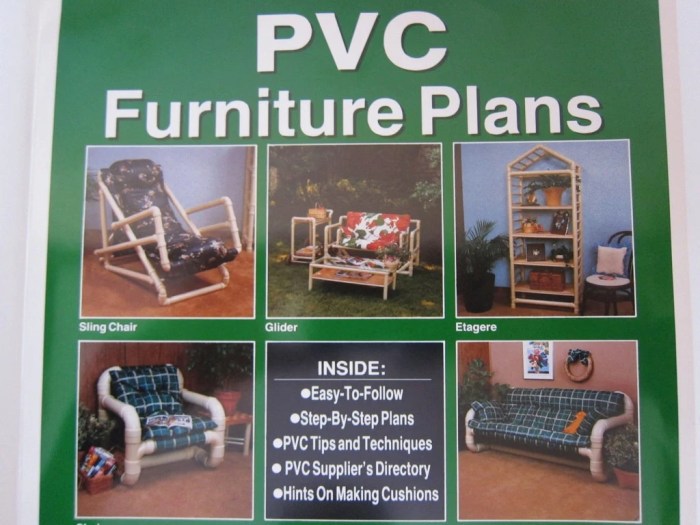

Examples of Popular PVC Furniture Plans

Here are some popular examples of PVC furniture plans:

Chairs

- Basic Folding Chair: This plan is simple and straightforward, suitable for beginners. It uses basic PVC pipe and fittings to create a sturdy and comfortable chair.

- Adirondack Chair: This plan is more complex and requires more intricate cutting and joining techniques. It results in a classic and comfortable chair perfect for outdoor use.

- Zero Gravity Chair: This plan is advanced and requires a high level of PVC fabrication skills. It involves custom-made components and a unique design to create a comfortable and relaxing chair.

Tables

- Simple Coffee Table: This plan is easy to follow and involves basic PVC pipe cutting and joining techniques. It creates a functional and stylish coffee table.

- Outdoor Dining Table: This plan is more complex and requires more intricate cutting and joining techniques. It results in a sturdy and spacious dining table perfect for outdoor gatherings.

- Adjustable Height Table: This plan is advanced and requires a high level of PVC fabrication skills. It involves custom-made components and a unique design to create a table with adjustable height settings.

Shelves

- Wall-Mounted Shelves: This plan is simple and straightforward, suitable for beginners. It uses basic PVC pipe and fittings to create sturdy and functional shelves.

- Corner Shelves: This plan is more complex and requires more intricate cutting and joining techniques. It creates a space-saving and stylish shelving solution.

- Modular Shelving System: This plan is advanced and requires a high level of PVC fabrication skills. It involves custom-made components and a unique design to create a versatile and customizable shelving system.

Choosing the Right PVC Furniture Plan

Choosing the right PVC furniture plan is crucial for a successful project. It involves carefully considering various factors to ensure you select a plan that aligns with your skills, tools, and desired outcome.

Understanding Your Skill Level and Available Tools

Your skill level and the tools you have available will significantly impact the type of PVC furniture plan you can successfully execute.

- Beginner: If you are new to PVC furniture building, start with simpler plans that involve basic cuts, joints, and assembly techniques. Look for plans with detailed instructions and diagrams, and consider projects that use fewer parts and require less intricate designs.

- Intermediate: With some experience, you can tackle more complex projects involving angled cuts, multiple joints, and more intricate designs. Consider plans that utilize various PVC fittings and require more precise measurements and assembly techniques.

- Advanced: If you have extensive experience with PVC furniture construction, you can explore challenging plans with intricate designs, custom fittings, and complex assembly procedures. These projects often involve advanced cutting techniques, specialized tools, and a high level of precision.

Evaluating the Complexity and Feasibility of a Plan

Before diving into a PVC furniture plan, take the time to assess its complexity and feasibility based on your skills, tools, and available resources.

- Number of Parts and Joints: Plans with a high number of parts and joints require more time, effort, and precision. Consider the complexity of each joint and the tools needed for their construction.

- Cutting Techniques: Some plans require specific cutting techniques, such as miter cuts, bevel cuts, or compound cuts. Ensure you have the necessary tools and knowledge to execute these cuts accurately.

- Assembly Instructions: Clear and detailed assembly instructions are essential for a successful project. Look for plans that provide step-by-step guidance, diagrams, and measurements.

- Material Requirements: Ensure you have access to the required PVC pipe sizes, fittings, and any additional materials specified in the plan. Consider the availability and cost of these materials.

Essential Tools and Materials

Before diving into the construction process, it’s crucial to gather the essential tools and materials required for building PVC furniture. Having the right equipment and materials ensures a smooth and efficient building experience, allowing you to create durable and stylish furniture.

Cutting Tools

Cutting PVC pipe accurately is a fundamental step in PVC furniture construction. The following tools are essential for achieving precise cuts:

- PVC Pipe Cutter: A dedicated PVC pipe cutter is designed to create clean and precise cuts without crushing or damaging the pipe. It features a rotating blade that scores the pipe and then cleanly severs it.

- Hand Saw: A hand saw with fine teeth can also be used for cutting PVC pipe, although it requires more effort and may result in less precise cuts.

- Miter Saw: For complex cuts and angles, a miter saw provides a highly accurate solution. It allows you to make precise angled cuts, ensuring that joints fit perfectly.

Joining Tools

Connecting PVC pipes and fittings is a key aspect of building furniture. The following tools facilitate strong and secure joints:

- PVC Primer: This liquid chemical helps clean the surface of the pipe and fitting, promoting a stronger bond with the adhesive.

- PVC Cement: This adhesive acts as a bonding agent, creating a permanent and waterproof seal between the pipe and fitting.

- PVC Pipe Cutter: A dedicated PVC pipe cutter is designed to create clean and precise cuts without crushing or damaging the pipe. It features a rotating blade that scores the pipe and then cleanly severs it.

- Hand Saw: A hand saw with fine teeth can also be used for cutting PVC pipe, although it requires more effort and may result in less precise cuts.

- Miter Saw: For complex cuts and angles, a miter saw provides a highly accurate solution. It allows you to make precise angled cuts, ensuring that joints fit perfectly.

Finishing Materials, Pvc furniture plans

After assembling your PVC furniture, you can enhance its appearance and durability with finishing materials:

- Sandpaper: Sanding the PVC surface removes any rough edges and prepares it for painting or other finishing treatments.

- Paint: A wide variety of paints, including acrylic, latex, and spray paints, can be used to add color and protection to PVC furniture.

- Stain: For a more natural look, wood stains can be applied to PVC furniture to mimic the appearance of wood.

- Polyurethane: A clear polyurethane coating provides a durable and protective finish, safeguarding the PVC from scratches, UV damage, and moisture.

Step-by-Step Construction Process: Pvc Furniture Plans

Now that you have your PVC furniture plans, it’s time to get your hands dirty and bring your design to life. The construction process involves a series of steps, each with its own set of techniques and tools.

Cutting PVC Components

Cutting PVC is a crucial step that requires precision and safety. You’ll be using a saw, and it’s important to choose the right type for the job. A miter saw is ideal for making precise cuts at specific angles, while a circular saw is great for straight cuts.

Here are the steps involved in cutting PVC:

- Measure and mark: Use a measuring tape and a pencil to mark the cutting lines on your PVC pipe or sheet. Ensure your markings are accurate, as any errors will be visible in the final product.

- Secure the PVC: Use a clamp or work bench to secure the PVC in place before cutting. This ensures a stable cutting surface and prevents movement, which can lead to inaccurate cuts.

- Make the cut: Use your chosen saw to make the cut along the marked line. Apply steady pressure and move the saw smoothly to avoid splintering or chipping the PVC.

- Deburr the edges: After cutting, use a deburring tool or sandpaper to smooth out any rough edges. This will prevent scratches and ensure a clean finish.

Joining PVC Components

Once you’ve cut your PVC pieces, it’s time to join them together. PVC can be joined using a variety of methods, including:

- Solvent cement: This is a common method for joining PVC pipes. The cement dissolves the surface of the PVC, creating a strong bond. When using solvent cement, it’s crucial to follow the manufacturer’s instructions carefully, as improper application can weaken the joint.

- PVC glue: This is a stronger alternative to solvent cement. It dries quickly and creates a durable bond. PVC glue is often used for joining PVC sheets and other non-pipe components.

- PVC fittings: These are specialized connectors designed to join PVC pipes and sheets. They come in a variety of shapes and sizes, allowing you to create different angles and configurations.

- Mechanical fasteners: For more robust connections, you can use screws, bolts, or rivets. These fasteners are particularly useful for joining PVC components that will experience heavy loads or stress.

Finishing PVC Furniture

After you’ve assembled your PVC furniture, you can enhance its appearance and protect it from the elements with a finishing touch. Here are some common finishing options:

- Painting: PVC can be painted with a variety of paints, including acrylic, latex, and enamel. Choose a paint that’s specifically designed for plastic to ensure good adhesion. Before painting, clean the PVC surface with soap and water to remove any dirt or grime.

- Vinyl wrapping: This is a quick and easy way to add color and texture to your PVC furniture. Vinyl wraps are available in a wide range of colors and patterns, allowing you to create a custom look. Apply the wrap using a squeegee to smooth out any air bubbles.

- Decals and stickers: For a more personalized touch, you can add decals or stickers to your PVC furniture. Choose decals that are specifically designed for plastic to ensure they adhere properly.

Design Considerations

Designing PVC furniture goes beyond simply assembling pieces. It involves carefully considering how form and function come together to create a piece that is both practical and aesthetically pleasing. This section will delve into key design elements that enhance the functionality and aesthetics of PVC furniture, providing tips for creating ergonomic seating, sturdy structures, and visually appealing designs.

PVC furniture plans are great for creating durable and easy-to-clean outdoor pieces. If you’re looking for a fun indoor project, though, check out these toybox woodworking plans – they’re a great way to get kids involved in building something special.

Once you’ve got your toybox built, you can use those leftover PVC pipes to create some fun storage shelves for all the new toys!

Ergonomic Seating

Ergonomic seating is crucial for comfort and support. PVC’s flexibility allows for creating contoured shapes that adapt to the human body, reducing strain and promoting proper posture.

- Consider the curvature of the backrest: A slight curve in the backrest can provide lumbar support, reducing strain on the lower back.

- Experiment with seat depth and angle: Proper seat depth ensures adequate thigh support, while the angle can promote blood circulation.

- Incorporate armrests: Armrests provide additional support and can help reduce strain on the shoulders and neck.

Sturdy Structures

PVC furniture’s strength lies in its ability to withstand stress and maintain its shape. To ensure a sturdy structure, consider these design principles:

- Reinforce joints: Use additional PVC pipes or fittings to strengthen areas where stress is likely to occur, such as corners and supports.

- Employ triangular bracing: Triangles are inherently strong shapes. Incorporate them into your design for added stability.

- Choose appropriate pipe sizes: Select pipe sizes based on the intended load and dimensions of the furniture.

Visually Appealing Designs

PVC furniture can be visually appealing, offering a wide range of design possibilities. Here are some tips for creating visually captivating pieces:

- Play with colors and patterns: PVC comes in various colors, allowing you to create vibrant and unique designs. Consider using contrasting colors or patterns to add visual interest.

- Incorporate decorative elements: Add decorative elements like fabric cushions, rope accents, or painted details to enhance the aesthetic appeal of your furniture.

- Experiment with shapes and forms: PVC’s flexibility allows for creating intricate shapes and forms. Explore different geometric patterns or curves to add visual interest.

Examples of PVC Furniture Designs

Here are a few examples of PVC furniture designs with unique features:

- Modular Lounging System: This design features interconnected PVC modules that can be arranged into various configurations, offering flexibility and customization.

- Outdoor Dining Set: This set features sturdy PVC tables and chairs designed for outdoor use, incorporating drainage holes and UV-resistant materials for durability.

- Children’s Play Structure: PVC can be used to create fun and interactive play structures for children, incorporating slides, climbing walls, and other engaging elements.

Finishing and Maintenance

You’ve built your PVC furniture, and now it’s time to give it the finishing touch. Finishing your PVC furniture not only enhances its appearance but also provides protection against the elements and wear and tear. Let’s explore different finishing options and learn how to keep your PVC furniture looking its best.

Finishing Options

Choosing the right finishing method for your PVC furniture depends on your desired aesthetic and the furniture’s intended use. Here are some popular options:

- Painting: Painting PVC furniture allows you to achieve a wide range of colors and finishes. It’s a versatile option for both indoor and outdoor furniture. Choose paints specifically designed for plastics, as they adhere better and provide a durable finish.

- Staining: Staining PVC furniture is not as common as painting, but it can create a natural, wood-like appearance. Stains are available in various shades and can enhance the texture of the PVC. Ensure you use a stain specifically formulated for plastics to ensure proper adhesion.

- Sealing: Sealing PVC furniture is essential for protecting it from the elements, especially if it’s used outdoors. Sealants create a protective barrier that repels water, UV rays, and dirt. Look for sealants specifically designed for PVC to ensure optimal protection.

- Vinyl Wraps: Vinyl wraps offer a quick and easy way to change the look of your PVC furniture. They come in a wide variety of colors, patterns, and textures. Vinyl wraps are also easy to apply and remove, allowing you to change the look of your furniture as often as you like.

Maintenance and Cleaning

PVC furniture is known for its durability and low maintenance requirements. Here are some tips for keeping your PVC furniture looking its best:

- Regular Cleaning: Regularly clean your PVC furniture with a mild soap and water solution. Avoid using harsh chemicals or abrasive cleaners, as they can damage the surface.

- Protect from Direct Sunlight: Prolonged exposure to direct sunlight can cause PVC to fade and become brittle. Consider using a UV-resistant sealant or placing your furniture under a canopy or awning to protect it from the sun.

- Store Properly: When not in use, store your PVC furniture in a dry, cool place. This will help prevent moisture buildup and protect the finish.

Safety Precautions

PVC furniture construction, while rewarding, requires prioritizing safety to prevent injuries. Proper handling of tools and materials, and working in a well-ventilated area are crucial aspects to consider.

Working with Tools

It’s essential to use tools safely and correctly to avoid accidents.

- Always wear safety glasses to protect your eyes from flying debris.

- Use gloves to protect your hands from cuts and abrasions when handling sharp tools.

- Ensure power tools are in good working condition and have safety guards in place.

- Keep tools sharp and clean to enhance their performance and prevent accidents.

- Store tools safely when not in use to prevent injuries and mishaps.

Handling PVC

PVC can be a versatile material, but handling it safely is crucial.

- Wear a dust mask when cutting or sanding PVC to prevent inhaling harmful particles.

- Avoid direct contact with PVC glue, as it can irritate skin. Wear gloves and ensure proper ventilation.

- Store PVC in a cool, dry place, away from direct sunlight, to prevent warping or discoloration.

- Properly dispose of PVC scraps, ensuring they are recycled or disposed of according to local regulations.

Working in a Well-Ventilated Area

PVC glue and other materials used in construction can release fumes that can be harmful.

- Work in a well-ventilated area, such as a garage with an open door or a workshop with a fan.

- Avoid working in enclosed spaces with poor ventilation, as this can lead to health risks.

- Use a respirator if you have respiratory issues or are working in a poorly ventilated area.

Inspiration and Resources

Building PVC furniture can be a fun and rewarding experience. It allows you to create unique and functional pieces that fit your style and needs. To get started, you’ll need inspiration and access to resources that can guide you through the process.

To spark your creativity, explore websites and online communities dedicated to PVC furniture building. These platforms offer a wealth of ideas, tutorials, and support from experienced builders.

Online Resources for PVC Furniture Plans

These online resources provide a starting point for finding PVC furniture plans, tutorials, and inspiration:

- Instructables: Instructables is a popular website that hosts a vast collection of DIY projects, including many PVC furniture plans. You can find step-by-step guides, photos, and user discussions on various PVC furniture designs.

- Pinterest: Pinterest is a visual search engine that allows you to discover ideas and inspiration. Search for “PVC furniture” or specific project types to find images, plans, and tutorials from various sources.

- YouTube: YouTube is a great platform for learning through video tutorials. Search for “PVC furniture DIY” or specific project types to find demonstrations, tips, and techniques from experienced builders.

- PVC Furniture Forums: Online forums dedicated to PVC furniture building offer a platform for sharing ideas, asking questions, and connecting with other enthusiasts. You can find forums by searching online or through social media groups.

Examples of Inspiring PVC Furniture Projects

Here are some examples of inspiring PVC furniture projects that demonstrate the versatility and creativity of this material:

- PVC Patio Furniture: This category includes chairs, tables, and loungers designed for outdoor use. PVC’s durability and weather resistance make it an ideal material for outdoor furniture.

- PVC Shelving Units: PVC pipes can be used to create sturdy and customizable shelving units for various purposes, such as bookshelves, storage shelves, and display shelves.

- PVC Play Structures: PVC’s lightweight and adaptable nature makes it perfect for building play structures for children. You can create slides, climbing frames, and other fun structures that encourage outdoor play.

- PVC Garden Trellises: PVC pipes can be used to create attractive and functional trellises for climbing plants in your garden. They provide support and structure for vines, flowers, and vegetables.

Final Review

Building PVC furniture is a rewarding experience that allows you to create custom pieces tailored to your needs and style. With the right plan, tools, and a little patience, you can transform basic PVC pipes into functional and stylish furniture that will last for years to come. So, get inspired, gather your materials, and embark on your own PVC furniture building journey. The possibilities are endless!

Clarifying Questions

What are the main benefits of using PVC for furniture?

PVC offers several advantages for furniture building, including its durability, weather resistance, affordability, and ease of workability. It’s also lightweight and easy to cut and join.

Where can I find free PVC furniture plans?

You can find a wide range of free PVC furniture plans online, on websites like Pinterest, Instructables, and various DIY blogs. Many online communities dedicated to PVC furniture building also share their plans and tutorials.

What type of PVC is best for furniture?

Schedule 40 PVC pipe is commonly used for furniture construction due to its strength and durability. However, you can also find PVC pipe specifically designed for furniture building, which may offer enhanced features like UV resistance.