Woodworking hardware is the unsung hero of every project, seamlessly blending form and function to bring your creations to life. From simple hinges and drawer slides to intricate decorative accents, this diverse range of components elevates woodworking from craft to art.

Whether you’re a seasoned craftsman or a budding DIY enthusiast, understanding woodworking hardware is crucial. It’s not just about aesthetics; it’s about choosing the right components for durability, functionality, and safety. This guide explores the world of woodworking hardware, covering everything from its fundamental role to the latest trends and innovations.

Introduction to Woodworking Hardware

Woodworking hardware is the essential component that brings functionality and aesthetic appeal to your woodworking projects. From simple hinges to intricate drawer slides, this hardware plays a crucial role in making your creations not only beautiful but also practical.

Types of Woodworking Hardware

Woodworking hardware encompasses a vast array of components, each serving a specific purpose in enhancing the functionality and appearance of your projects.

- Hinges: Hinges are the fundamental hardware for doors, lids, and other movable parts, allowing them to swing open and close smoothly. There are various types of hinges available, including butt hinges, concealed hinges, and piano hinges, each offering distinct advantages depending on the project’s requirements.

- Drawer Slides: Drawer slides ensure smooth and effortless operation of drawers. They come in various styles, such as side-mount, under-mount, and full-extension slides, each providing different levels of extension and weight capacity.

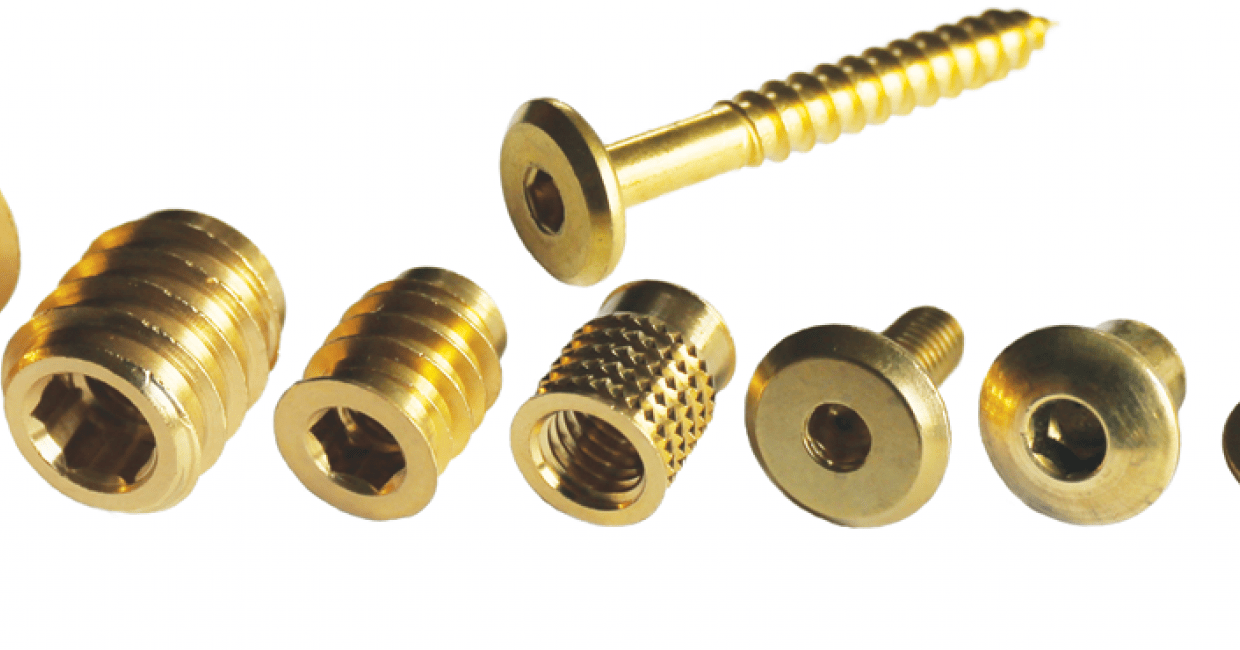

- Fasteners: Fasteners, such as screws, nails, and bolts, are essential for assembling and securing woodworking components. They come in a wide range of materials, sizes, and finishes, allowing you to choose the best option for your specific needs.

- Handles and Knobs: Handles and knobs add functionality and aesthetic appeal to doors, drawers, and cabinets. They are available in various materials, styles, and finishes, allowing you to personalize your projects.

- Latches and Locks: Latches and locks provide security and privacy for doors, cabinets, and other enclosed spaces. They come in various types, including deadbolt locks, lever handles, and magnetic catches, each offering distinct levels of security.

- Casters and Wheels: Casters and wheels allow furniture and other woodworking projects to move easily and smoothly. They come in various sizes, materials, and load capacities, depending on the intended use and weight capacity.

- Cabinet Hardware: Cabinet hardware encompasses a wide range of components specifically designed for cabinets, including door hinges, drawer slides, handles, knobs, and shelf supports. This hardware ensures functionality, organization, and aesthetic appeal for your cabinetry projects.

- Furniture Hardware: Furniture hardware includes a wide range of components used in furniture construction, including legs, glides, brackets, and upholstery hardware. This hardware provides structural support, stability, and aesthetic appeal to your furniture projects.

Types of Woodworking Hardware

Woodworking hardware refers to the various components and fittings used to assemble, secure, and enhance woodworking projects. These components play a crucial role in functionality, aesthetics, and overall project stability.

Types of Woodworking Hardware

Woodworking hardware encompasses a wide range of components, each designed for specific applications. Here’s a breakdown of some common types:

| Hardware Type | Description | Applications | Examples |

|---|---|---|---|

| Hinges | These are metal or plastic components used to connect two surfaces, allowing one to swing or fold. | Doors, cabinets, lids, and other movable elements. | Butt hinges, piano hinges, concealed hinges, and offset hinges. |

| Knobs and Handles | These are used for opening and closing doors, drawers, and cabinets. | Doors, drawers, cabinets, and other movable elements. | Cabinet knobs, door handles, drawer pulls, and furniture handles. |

| Fasteners | These are used to join or secure two or more pieces of wood. | Joining wood components, securing furniture, and attaching hardware. | Screws, nails, staples, bolts, and nuts. |

| Slides | These are metal components used to allow smooth movement of drawers, shelves, and other sliding elements. | Drawers, shelves, sliding doors, and other movable elements. | Full-extension slides, soft-close slides, undermount slides, and side-mount slides. |

| Latches and Locks | These are used to secure doors, drawers, and other movable elements. | Doors, drawers, cabinets, and other movable elements. | Deadbolts, lever handles, magnetic latches, and hasp and staple latches. |

| Casters and Wheels | These are used to make furniture and other objects movable. | Furniture, carts, and other movable objects. | Swivel casters, rigid casters, and heavy-duty casters. |

| Cabinet Hardware | These are specific components designed for cabinets and other storage units. | Cabinets, shelves, drawers, and other storage elements. | Cabinet hinges, drawer slides, cabinet knobs, and cabinet pulls. |

| Furniture Hardware | These are components specifically designed for furniture. | Furniture, chairs, tables, and other furniture elements. | Furniture legs, casters, furniture hinges, and furniture knobs. |

| Door Hardware | These are components specifically designed for doors. | Doors, gates, and other door elements. | Door hinges, door handles, door knobs, and door locks. |

Materials Used in Woodworking Hardware

Woodworking hardware is typically made from various materials, each with its own advantages and disadvantages.

- Metal: Metals, such as steel, brass, aluminum, and iron, are widely used for their strength, durability, and resistance to wear and tear. Steel is a popular choice for hinges, fasteners, and slides due to its high strength and affordability. Brass is often used for decorative hardware due to its attractive finish and resistance to corrosion. Aluminum is lightweight and corrosion-resistant, making it suitable for furniture and other applications where weight is a concern. Iron is a durable and affordable option for basic hardware.

- Plastic: Plastic is becoming increasingly popular in woodworking hardware due to its lightweight, affordable, and corrosion-resistant properties. Plastic is often used for knobs, handles, and some types of hinges and slides. However, plastic hardware may not be as durable as metal hardware, especially in high-wear applications.

- Wood: Wood is sometimes used for decorative hardware, such as knobs and pulls. Wooden hardware can add a natural and rustic touch to projects. However, wood is not as durable as metal or plastic and can be susceptible to moisture damage.

Choosing the Right Woodworking Hardware

Choosing the right woodworking hardware is essential for creating durable and functional projects. The right hardware can make a significant difference in the overall quality, appearance, and longevity of your work. It’s not just about aesthetics; selecting the correct hardware ensures your project functions as intended.

Factors to Consider

It’s crucial to consider several factors when choosing woodworking hardware for specific projects. This includes the type of wood you are working with, the intended use of the project, and the desired aesthetic. Understanding these factors will help you make informed decisions.

- Type of Wood: Different types of wood have varying densities and strengths. Hardwoods, like oak and maple, require heavier-duty hardware than softwoods, like pine or fir. This ensures the hardware can withstand the stress of the wood.

- Intended Use: The intended use of your project dictates the type of hardware required. For example, a cabinet door hinge will need to be strong enough to support the weight of the door, while a drawer slide should be smooth and easy to operate.

- Desired Aesthetic: The aesthetic of your project should be considered when choosing hardware. There are many styles of hardware available, ranging from traditional to modern. Selecting hardware that complements the overall design will enhance the project’s visual appeal.

Selecting Hardware Based on Material, Size, Style, and Functionality

Once you’ve considered the factors above, you can narrow down your choices based on material, size, style, and functionality.

- Material: Woodworking hardware is typically made from metal, plastic, or wood. Metal hardware, like steel or brass, is durable and long-lasting. Plastic hardware is often less expensive but may not be as strong. Wood hardware, like dowels or pegs, is often used for traditional projects.

- Size: The size of the hardware you choose should be appropriate for the project. For example, a small hinge may not be strong enough to support a large door. Similarly, a large drawer slide may be too bulky for a small drawer.

- Style: The style of the hardware should complement the overall design of the project. There are many different styles of hardware available, from simple and minimalist to ornate and decorative.

- Functionality: The functionality of the hardware is crucial. For example, a drawer slide should be smooth and easy to operate. A door hinge should be strong and durable enough to support the weight of the door.

Decision-Making Process, Woodworking hardware

To ensure you choose the right hardware, follow this decision-making process:

- Identify the project: Determine the type of project you’re working on, such as a cabinet, table, or chair.

- Define the hardware’s purpose: Identify the specific function of the hardware, such as hinges for doors, slides for drawers, or fasteners for joining pieces.

- Consider the material: Choose a material that suits the project’s durability and aesthetic requirements, such as metal, plastic, or wood.

- Determine the size and style: Select hardware that complements the project’s size and style.

- Assess functionality: Ensure the hardware is functional and easy to use, considering the intended use and weight of the project.

- Compare options: Research different hardware options and compare their features, prices, and reviews.

- Make the final decision: Choose the hardware that best meets the project’s needs and your budget.

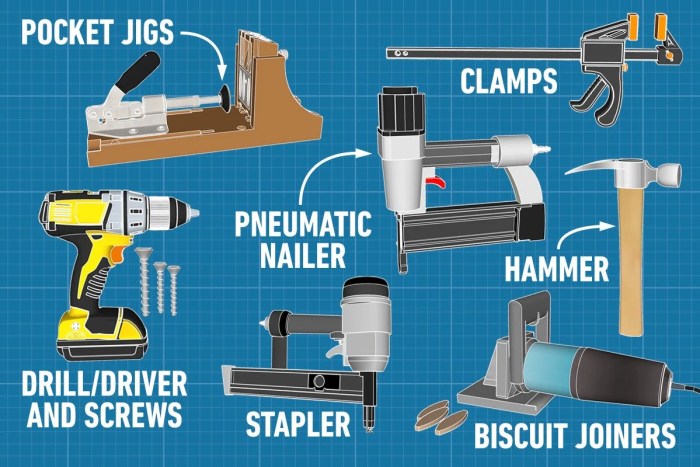

Installation and Use of Woodworking Hardware

Installing woodworking hardware is a crucial step in completing any woodworking project. Proper installation ensures that your hardware functions correctly and lasts for years to come. It also enhances the overall aesthetics and durability of your project.

Installing Hinges

Hinges are used to attach doors, lids, and other movable parts to cabinets, boxes, and other structures. They are available in various styles, sizes, and materials, each suited for specific applications. Here’s a breakdown of installing different types of hinges:

Installing Butt Hinges

Butt hinges are the most common type of hinge used in woodworking. They are simple, durable, and relatively inexpensive. To install butt hinges, follow these steps:

- Mark the hinge location: Use a pencil to mark the hinge location on both the door and the frame. Ensure the marks are aligned perfectly.

- Drill pilot holes: Drill pilot holes for the hinge screws. The holes should be slightly smaller than the screw diameter. This prevents the wood from splitting.

- Attach the hinge leaves: Place one hinge leaf on the door and the other on the frame, aligning them with the marked locations. Secure the hinges using the screws.

- Adjust the hinge: Once the hinges are installed, adjust them to ensure the door opens and closes smoothly.

Installing European Hinges

European hinges, also known as concealed hinges, are designed to be hidden from view when the door is closed. They are often used in modern cabinets and furniture. Here’s how to install European hinges:

- Mark the hinge location: Use a template or measuring tool to mark the hinge location on the door and the cabinet.

- Drill pilot holes: Drill pilot holes for the hinge screws. The holes should be slightly smaller than the screw diameter.

- Install the hinge plate: Attach the hinge plate to the cabinet using the screws.

- Install the hinge cup: Align the hinge cup with the marked location on the door and press it into the wood. Use a countersinking tool to create a recess for the hinge cup.

- Attach the door: Align the door with the hinge plate and secure it with the hinge cup.

Installing Piano Hinges

Piano hinges are long, continuous hinges that are commonly used for attaching lids, doors, and other movable parts to large structures. They are known for their strength and durability. Here’s how to install piano hinges:

- Mark the hinge location: Measure and mark the hinge location on both the door and the frame. Ensure the marks are aligned perfectly.

- Drill pilot holes: Drill pilot holes for the hinge screws. The holes should be slightly smaller than the screw diameter.

- Attach the hinge: Place the hinge on the door and the frame, aligning it with the marked locations. Secure the hinge using the screws.

- Adjust the hinge: Once the hinge is installed, adjust it to ensure the door opens and closes smoothly.

Installing Drawer Slides

Drawer slides are essential for smooth and reliable drawer operation. They come in various styles, including side-mount, under-mount, and full-extension slides.

Installing Side-Mount Drawer Slides

Side-mount drawer slides are attached to the sides of the drawer and the cabinet. They are a common choice for drawers with limited depth. Here’s how to install side-mount drawer slides:

- Measure and mark: Measure the drawer opening and mark the slide locations on the drawer sides and the cabinet sides.

- Attach the slides: Secure the slides to the drawer sides and the cabinet sides using the provided screws. Ensure the slides are aligned correctly.

- Install the drawer: Align the drawer with the slides and slide it into place.

Installing Under-Mount Drawer Slides

Under-mount drawer slides are attached to the bottom of the drawer and the cabinet. They provide a clean, modern look and allow for full-extension functionality. Here’s how to install under-mount drawer slides:

- Measure and mark: Measure the drawer opening and mark the slide locations on the bottom of the drawer and the cabinet.

- Attach the slides: Secure the slides to the bottom of the drawer and the cabinet using the provided screws. Ensure the slides are aligned correctly.

- Install the drawer: Align the drawer with the slides and slide it into place.

Installing Full-Extension Drawer Slides

Full-extension drawer slides allow the drawer to extend completely, providing easy access to the contents. They are often used in kitchens and bathrooms. Here’s how to install full-extension drawer slides:

- Measure and mark: Measure the drawer opening and mark the slide locations on the drawer sides and the cabinet sides.

- Attach the slides: Secure the slides to the drawer sides and the cabinet sides using the provided screws. Ensure the slides are aligned correctly.

- Install the drawer: Align the drawer with the slides and slide it into place.

Installing Cabinet Knobs and Pulls

Cabinet knobs and pulls are decorative hardware used to open drawers and doors. They are available in a wide range of styles, sizes, and materials. Here’s how to install cabinet knobs and pulls:

- Mark the knob or pull location: Use a pencil to mark the knob or pull location on the drawer or door. Ensure the marks are centered and aligned.

- Drill pilot holes: Drill pilot holes for the knob or pull screws. The holes should be slightly smaller than the screw diameter.

- Attach the knob or pull: Align the knob or pull with the marked location and secure it using the screws.

Installing Woodworking Hardware Tips

Here are some additional tips for installing woodworking hardware:

- Use the right tools: Using the correct tools for the job will make the installation process easier and more accurate.

- Pre-drill pilot holes: Pre-drilling pilot holes will prevent the wood from splitting when driving screws.

- Use the right screws: Use screws that are the correct length and diameter for the application.

- Tighten screws securely: Ensure that the screws are tightened securely to prevent the hardware from loosening over time.

- Test the hardware: After installation, test the hardware to ensure it is working properly.

Woodworking Hardware Trends and Innovations

The world of woodworking hardware is constantly evolving, with new materials, designs, and functionalities emerging to meet the demands of both professional and hobbyist woodworkers. This section explores the latest trends in woodworking hardware, innovative solutions for specific applications, and potential future advancements in this field.

Sustainable and Eco-Friendly Hardware

As sustainability gains increasing importance, the woodworking hardware industry is responding with eco-conscious options.

- Recycled Materials: Many manufacturers are using recycled materials like aluminum and steel to produce hardware components. This reduces the environmental impact of production and promotes a circular economy.

- Bio-Based Materials: Innovative materials derived from renewable sources, such as bamboo and hemp, are being incorporated into hardware designs. These materials offer a sustainable alternative to traditional plastics and metals.

- Energy-Efficient Manufacturing: Companies are implementing energy-efficient practices in their manufacturing processes, reducing their carbon footprint and promoting sustainable production.

Smart Hardware and Automation

The integration of technology into woodworking hardware is opening up new possibilities for precision, efficiency, and customization.

- Smart Hinges: Hinges with built-in sensors can monitor door opening and closing, providing data for analytics and automation. They can also trigger actions like lighting or security systems.

- Automated Drawer Systems: Drawer systems with integrated motors and controls allow for smooth, quiet operation and customizable settings for opening and closing speed.

- 3D Printing for Hardware: 3D printing technology enables the creation of customized hardware solutions tailored to specific woodworking projects. This opens up possibilities for unique designs and intricate details.

Innovative Solutions for Specific Applications

- Concealed Hardware: Hidden hinges, drawer slides, and other hardware elements create a sleek and minimalist aesthetic, emphasizing the beauty of the wood itself.

- Lightweight Hardware: Lightweight hardware solutions are gaining popularity for furniture and other applications where weight is a factor. This is particularly important for portable furniture and structures.

- High-Performance Hardware: For demanding applications like outdoor furniture and heavy-duty cabinets, hardware designed for durability, weather resistance, and high load capacity is essential.

Future Advancements in Woodworking Hardware

The future of woodworking hardware is likely to be characterized by even greater integration of technology, sustainable materials, and personalized solutions.

- Advanced Materials: New materials with enhanced properties, such as strength, durability, and flexibility, will be developed and incorporated into hardware designs.

- Artificial Intelligence (AI): AI-powered hardware will offer self-learning capabilities, adapting to user preferences and optimizing performance over time.

- Augmented Reality (AR): AR technology will be used to visualize and interact with hardware in real-time, enhancing the design and installation process.

Woodworking Hardware Safety and Maintenance

Woodworking hardware can be dangerous if not handled and used correctly. Proper maintenance can help extend the lifespan of your hardware and prevent accidents.

Safety Guidelines for Handling and Using Woodworking Hardware

Always wear safety glasses when working with woodworking hardware, as flying debris can cause eye injuries. Use a work surface that is stable and secure to prevent hardware from falling and causing injury. Be sure to keep your workspace clean and organized to avoid tripping hazards. Always follow the manufacturer’s instructions for using and installing woodworking hardware. If you are unsure of how to use a piece of hardware, consult a professional.

Maintenance Practices for Woodworking Hardware

- Hinges: Regularly lubricate hinges with a light oil or grease to prevent squeaking and rust. Clean hinges with a soft cloth and mild detergent to remove dirt and debris.

- Knobs and Handles: Clean knobs and handles with a soft cloth and mild detergent. Avoid using abrasive cleaners or harsh chemicals that can damage the finish. For wooden knobs and handles, consider applying a wood polish to maintain their appearance.

- Slides: Clean slides with a soft cloth and mild detergent. Lubricate slides with a light oil or grease to prevent friction and wear. If slides are making noise, check for any debris or misalignment and adjust as needed.

- Fasteners: Check screws and nails regularly for signs of loosening or damage. Tighten loose fasteners to prevent them from coming loose and causing damage. Replace damaged fasteners with new ones of the same size and type.

Preventing Hardware Wear and Tear

- Use the Right Hardware: Choose hardware that is appropriate for the weight and use of the project. Overloading hardware can lead to premature wear and tear.

- Proper Installation: Install hardware correctly according to the manufacturer’s instructions. Incorrect installation can lead to damage and failure.

- Regular Inspection: Inspect hardware regularly for signs of wear and tear. Replace damaged or worn hardware as needed.

- Proper Storage: Store hardware in a dry, clean place to prevent rust and corrosion. Keep hardware organized and labeled to make it easy to find what you need.

Closing Summary

As you delve deeper into the world of woodworking hardware, remember that each component plays a vital role in the overall success of your project. From the sturdiness of hinges to the smooth glide of drawer slides, every piece contributes to the functionality and longevity of your creations. Embrace the versatility of woodworking hardware, and let it inspire you to build lasting pieces that stand the test of time.

Questions and Answers

What are some common woodworking hardware materials?

Woodworking hardware is typically made from durable materials like metal (steel, brass, aluminum), plastic, and sometimes wood itself. The choice of material depends on the hardware’s function, desired aesthetic, and project requirements.

How do I choose the right hardware for my project?

Consider factors like the size and weight of the project, the desired style, functionality, and the material of the wood you’re working with. Consult with a hardware specialist or research online resources for guidance.

Where can I find woodworking hardware?

Woodworking hardware is readily available at home improvement stores, specialty woodworking shops, and online retailers. You can also find unique and custom hardware from specialized suppliers.

Woodworking hardware is the backbone of any project, from simple shelves to intricate furniture. Choosing the right hinges, drawer slides, and fasteners can make a huge difference in the final look and functionality of your piece. To find inspiration for your next woodworking project, check out this website for woodwork projects that will spark your creativity.

Once you have a design in mind, you can start gathering the appropriate hardware to bring your vision to life.