Woodworking plans benches are your gateway to crafting sturdy, functional, and personalized workspaces. These plans offer detailed blueprints and instructions, guiding you through every step of the construction process, from selecting the right wood to assembling the final piece. Whether you’re a seasoned woodworker or just starting out, having a well-designed workbench is essential for tackling a wide range of projects.

From traditional to modern styles, woodworking benches come in various shapes and sizes, each tailored to specific needs. Understanding the different types of benches, their components, and the tools required for construction will empower you to build a bench that perfectly suits your workshop and woodworking style. This guide will walk you through the essential steps of building a woodworking bench, from planning to finishing, ensuring you create a durable and reliable workspace that will last for years to come.

Introduction to Woodworking Benches

A woodworking bench is an essential tool for any woodworker, providing a stable and sturdy platform for working on projects. It is a versatile piece of equipment that has been used for centuries, evolving over time to meet the needs of woodworkers.

Woodworking benches have a rich history, dating back to ancient civilizations. Early benches were simple structures made of wood, often with a single vise. Over time, the design of benches became more sophisticated, with features such as multiple vises, tool trays, and work surfaces designed for specific tasks.

Key Features and Functionalities

Woodworking benches are designed to provide a stable and secure platform for working on wood. They typically feature a sturdy base, a flat work surface, and a vise or multiple vises.

Here are some of the key features and functionalities of a woodworking bench:

- Work Surface: The work surface is the primary area for working on projects. It should be flat, smooth, and durable, capable of withstanding the weight of tools and materials. The size and shape of the work surface will vary depending on the type of woodworking being done.

- Vise: A vise is a clamping device that holds the workpiece securely in place. Woodworking benches typically have at least one vise, often located on the front edge of the bench. The vise allows the woodworker to hold the workpiece firmly while cutting, shaping, or assembling it.

- Tool Trays: Tool trays are often incorporated into the design of woodworking benches, providing a convenient way to store and organize tools. These trays can be located on the side of the bench, under the work surface, or even integrated into the bench top.

- Storage: Woodworking benches often include storage compartments or shelves for storing tools, materials, and other supplies. This can help keep the work area organized and efficient.

- Leg Design: The leg design of a woodworking bench is important for stability and durability. The legs should be strong and well-supported, capable of handling the weight of the bench and the work being done on it.

Types of Woodworking Benches

Woodworking benches come in a variety of shapes and sizes, each designed for a specific purpose. The type of bench you choose will depend on the types of woodworking projects you plan to undertake, the space you have available, and your budget.

Traditional Woodworking Benches

Traditional woodworking benches are typically made from solid wood, such as oak or maple. They feature a sturdy top with a vise that can be used to secure your workpiece. Traditional benches are known for their durability and stability. They are also versatile and can be used for a wide range of woodworking tasks.

- Advantages: Traditional woodworking benches are durable, stable, and versatile. They are also relatively inexpensive to build.

- Disadvantages: Traditional benches can be heavy and bulky. They may also require more space than other types of benches.

Modern Woodworking Benches

Modern woodworking benches are often made from metal or a combination of metal and wood. They are typically lighter and more compact than traditional benches. Modern benches often feature adjustable features, such as height and vise positions.

- Advantages: Modern woodworking benches are lightweight, compact, and adjustable. They are also often more affordable than traditional benches.

- Disadvantages: Modern benches may not be as durable as traditional benches. They may also lack the versatility of traditional benches.

Specialized Woodworking Benches

Specialized woodworking benches are designed for specific tasks. For example, there are benches designed for woodworking with hand tools, benches designed for woodworking with power tools, and benches designed for woodworking with specific types of wood.

- Advantages: Specialized benches are designed for specific tasks, which makes them more efficient and effective.

- Disadvantages: Specialized benches can be expensive. They may also be less versatile than traditional or modern benches.

Examples of Popular Bench Styles

Here are some examples of popular woodworking bench styles:

- The Roubo Bench: This traditional bench is known for its durability and versatility. It features a thick, sturdy top and a vise that can be used to secure workpieces of various sizes.

- The Workbench: This modern bench is designed for both hand and power tools. It features a lightweight aluminum frame and a durable work surface. It is also adjustable in height and vise position.

- The Sawbench: This specialized bench is designed for woodworking with a saw. It features a large, flat work surface and a saw guide that helps to ensure accurate cuts.

Essential Components of a Woodworking Bench

A woodworking bench is more than just a surface to work on; it’s a vital tool that provides stability, support, and functionality for your projects. Its components are designed to enhance your woodworking experience and make your tasks easier and more efficient.

The essential components of a woodworking bench include the top, base, vise, and accessories. Each element plays a crucial role in providing the necessary support and functionality for your woodworking endeavors.

Bench Top

The bench top is the primary working surface of the bench. It should be sturdy, flat, and resistant to wear and tear. Common materials for bench tops include:

- Hardwoods like maple, cherry, or oak, known for their durability and resistance to denting.

- Softwoods like pine or fir, which are less expensive but may require more maintenance.

- Engineered wood products like plywood or MDF, which offer a cost-effective alternative.

The thickness of the bench top is also important, with thicker tops providing greater stability and resistance to warping. A well-constructed bench top should be smooth and free of any imperfections that could hinder your work.

Bench Base

The base provides the structural support for the bench top. It should be strong and stable to prevent the bench from wobbling or collapsing under the weight of your projects and tools. Common base designs include:

- Traditional legs: These are typically made from hardwood and are often joined with mortise-and-tenon joints or similar joinery techniques. Traditional legs offer a classic look and provide good stability.

- Metal legs: Metal legs are often used for benches designed for heavy-duty use. They are typically made from steel or aluminum and can be welded or bolted together. Metal legs are strong and durable, but they can be more expensive than traditional legs.

- Trestle base: A trestle base uses two vertical supports with a horizontal beam connecting them. Trestle bases are often used for benches that need to be easily moved. They can be made from wood or metal.

The base should be designed to provide ample legroom and allow for easy access to the underside of the bench for storage or tool organization.

Bench Vise

A bench vise is a crucial component of a woodworking bench, providing a secure clamping mechanism for holding and working on your projects. The vise is typically mounted to the bench top and consists of two jaws that can be tightened together to grip your workpiece.

There are various types of bench vises, each designed for specific purposes. Choosing the right vise depends on the type of woodworking you do and the size of the projects you typically work on.

Types of Bench Vises

- Quick-release vise: This type of vise uses a lever or handle to quickly open and close the jaws. Quick-release vises are often preferred for tasks that require frequent adjustments. They are typically less expensive than other types of vises.

- Screw vise: This type of vise uses a screw to tighten the jaws. Screw vises are known for their strength and precision. They can provide a very strong clamping force, making them ideal for heavy-duty work. However, they can be more difficult to adjust than quick-release vises.

- Parallel vise: This type of vise uses a system of parallel bars to keep the jaws aligned. Parallel vises are often used for tasks that require precise clamping, such as woodworking joinery. They are typically more expensive than other types of vises.

- Tail vise: This type of vise is mounted to the end of the bench top and can be used to hold long workpieces. Tail vises are often used for tasks like planing or sanding long boards. They are typically more expensive than other types of vises.

- Woodworker’s vise: This type of vise is designed specifically for woodworking. It typically has a large jaw opening and a strong clamping force. Woodworker’s vises are often preferred for tasks that require a secure grip, such as cutting or shaping wood.

When choosing a vise, consider the following factors:

- Jaw opening: This refers to the distance between the jaws when they are fully open. Choose a vise with a jaw opening that is large enough to accommodate the size of your projects.

- Clamping force: This refers to the amount of force that the vise can exert on your workpiece. Choose a vise with a clamping force that is strong enough for the tasks you plan to do.

- Ease of use: Some vises are easier to adjust than others. Choose a vise that is comfortable and easy to use for your specific needs.

- Durability: Choose a vise that is made from durable materials and is well-constructed. A well-made vise will last for many years.

Accessories

In addition to the essential components of the bench top, base, and vise, many other accessories can enhance the functionality and usefulness of a woodworking bench. These accessories include:

- Dog holes: These are holes drilled into the bench top that allow you to use bench dogs to hold your workpieces in place. Bench dogs are small, movable blocks that fit into the dog holes and can be used to support and secure your workpieces.

- Holdfasts: These are metal clamps that are used to secure workpieces to the bench top. Holdfasts are often used for tasks that require a firm grip, such as planing or carving.

- Tool holders: These are devices that can be mounted to the bench top or sides to store and organize your tools. Tool holders can help keep your workspace tidy and organized.

- Storage shelves: These can be added to the underside of the bench or to the sides to provide additional storage space for tools, materials, and projects.

Choosing the right accessories for your bench depends on your individual needs and preferences. However, even a few well-chosen accessories can significantly improve your woodworking experience.

Building a sturdy bench is a great woodworking project for beginners. You can find tons of plans online, but if you want some inspiration and detailed instructions, check out woodworking magazine. They have a huge archive of articles and plans, including some awesome bench designs.

Once you’ve got your plan, gather your tools and materials, and get ready to build something beautiful and functional.

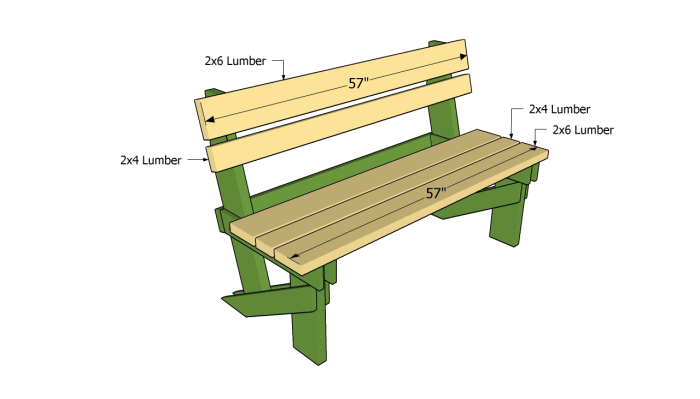

Materials and Construction

Choosing the right materials and construction techniques is crucial for building a durable and functional woodworking bench. The materials you choose will affect the bench’s strength, stability, and longevity.

Hardwoods like maple, cherry, or oak are often preferred for bench tops and bases due to their durability and resistance to wear and tear. However, these woods can be expensive. Softwoods like pine or fir are less expensive but may require more maintenance. Engineered wood products like plywood or MDF can be cost-effective alternatives, but they may not be as durable as hardwoods. For the base, metal legs can provide excellent strength and stability, especially for benches designed for heavy-duty use. However, they can be more expensive than traditional wooden legs.

The construction techniques you use will also affect the bench’s strength and stability. Strong joinery techniques, such as mortise-and-tenon joints, are essential for creating a durable and stable bench. Using glue and screws in conjunction with joinery can further enhance the strength of the bench.

If you are building a bench from scratch, take the time to carefully plan your design and choose the right materials and construction techniques. A well-constructed bench will provide you with many years of reliable service.

Building a Woodworking Bench from Plans

Building a woodworking bench from plans offers a structured and organized approach, ensuring you create a sturdy and functional workspace. Plans provide detailed instructions, material lists, and diagrams, making the construction process straightforward and less prone to errors.

Reliable Sources for Woodworking Bench Plans

Finding reliable sources for woodworking bench plans is essential for successful construction.

- Online Woodworking Communities and Forums: Websites like Lumberjocks, Woodworking Talk, and Reddit’s woodworking subreddit offer a wealth of free and paid plans, often shared by experienced woodworkers. These communities provide a platform for exchanging knowledge and sharing project ideas, fostering a collaborative environment.

- Woodworking Magazines and Books: Publications like Fine Woodworking, Popular Woodworking, and Woodsmith magazine often feature detailed woodworking bench plans. These resources provide in-depth instructions and insights from professional woodworkers.

- Commercial Woodworking Plan Providers: Companies like Woodcraft, Rockler, and Woodworking for Mere Mortals offer a wide range of woodworking bench plans, both free and paid. These providers typically offer high-quality plans with detailed instructions and support.

Popular Woodworking Bench Plans

Numerous popular woodworking bench plans are available, catering to various needs and skill levels.

- The Roubo Bench: This classic bench design, inspired by the 18th-century French cabinetmaker André Roubo, is known for its robust construction and versatility. It features a sturdy workbench top, a vise, and a tail vise, making it suitable for a wide range of woodworking tasks. Roubo bench plans are readily available online and in woodworking books.

- The Workbench from “The Anarchist’s Design Book”: This bench design, popularized by Christopher Schwarz, emphasizes simplicity and efficiency. It features a strong and stable base, a benchtop with a built-in vise, and a simple but effective construction method. This plan is often favored by woodworkers seeking a durable and functional bench without unnecessary complexity.

- The “Sawbench” Design: This design, developed by Tage Frid, is specifically tailored for woodworking tasks involving saws. It features a long and narrow benchtop, a sturdy base, and a dedicated sawbench vise, making it ideal for accurate and precise sawing operations.

Choosing the Right Wood for a Woodworking Bench

A woodworking bench is a significant investment, and choosing the right wood for its construction is crucial for its longevity and performance. The wood you select will impact its durability, stability, and overall usability.

Various wood species possess unique properties that make them suitable for different woodworking applications. Some woods are known for their strength and hardness, while others are prized for their workability and aesthetic appeal. Understanding these characteristics is essential for selecting the best wood for your bench.

Wood Properties for Woodworking Benches

The following table compares the properties of several common wood species used for building woodworking benches.

| Wood Species | Hardness (Janka Scale) | Durability | Workability | Cost |

|---|---|---|---|---|

| Hard Maple | 1450 | Very Durable | Moderately Difficult | High |

| Red Oak | 1290 | Durable | Moderately Difficult | Moderate |

| Cherry | 995 | Durable | Easy | High |

| Walnut | 1010 | Durable | Easy | Very High |

| Pine | 560 | Not Durable | Very Easy | Low |

| Douglas Fir | 690 | Durable | Moderately Difficult | Moderate |

The Janka scale measures the resistance of wood to indentation. A higher Janka rating indicates a harder wood, making it more resistant to dents and scratches.

Considering Intended Use and Budget

When selecting wood for your bench, consider the intended use and your budget. If you plan to use your bench for heavy-duty woodworking tasks, a harder wood like maple or oak is a better choice. For lighter tasks or if you are on a tighter budget, softer woods like pine or fir can be suitable.

Tools and Techniques for Building a Woodworking Bench

Building a woodworking bench is a rewarding project that involves various tools and techniques. This section delves into the essential tools you’ll need and the common woodworking techniques used in bench construction, including cutting, joining, and finishing.

Essential Tools

Having the right tools is crucial for building a sturdy and functional woodworking bench. The following list Artikels the essential tools needed:

- Measuring Tools: Accurate measurements are the foundation of any woodworking project. A tape measure, ruler, and combination square are essential for precise measurements.

- Cutting Tools: Cutting wood to size is a fundamental step in bench construction. A circular saw, table saw, or hand saw can be used for cutting lumber. A jigsaw or scroll saw is useful for intricate cuts.

- Joining Tools: Woodworking benches require strong and durable joints. A drill, drill bits, and a countersinking tool are essential for creating pilot holes and countersinking screws. Clamps are indispensable for holding pieces together while gluing or screwing them.

- Finishing Tools: A sander, sanding paper, and a finishing brush or sprayer are used to smooth the surface and apply a protective finish to the bench.

Common Woodworking Techniques

Woodworking techniques are essential for building a durable and aesthetically pleasing bench. Some common techniques include:

- Cutting: Cutting wood to size is a fundamental step. Using a circular saw, table saw, or hand saw allows for precise and clean cuts.

- Joining: Joining wood pieces together is crucial for creating a sturdy bench. Common joining methods include:

- Butt Joints: The simplest joint, where two pieces of wood are butted together.

- Dado Joints: A groove is cut into one piece of wood, and a corresponding tongue is cut into the other piece, creating a strong and secure joint.

- Mortise and Tenon Joints: A tenon is cut on one piece of wood and fits into a mortise cut into the other piece, creating a strong and durable joint.

- Dovetail Joints: A complex joint with interlocking pieces, creating a very strong and visually appealing joint.

- Finishing: Finishing the bench involves smoothing the surface and applying a protective coating. Sanding is crucial for achieving a smooth surface. Various finishes can be applied, such as paint, stain, or varnish, depending on the desired aesthetic and protection level.

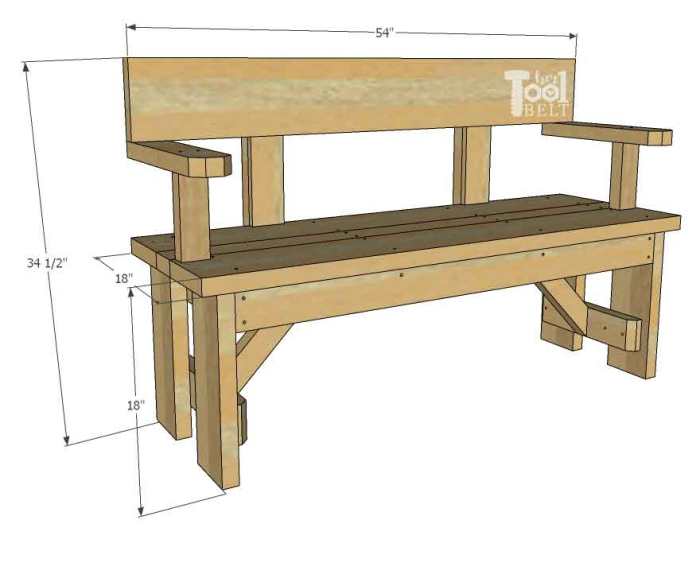

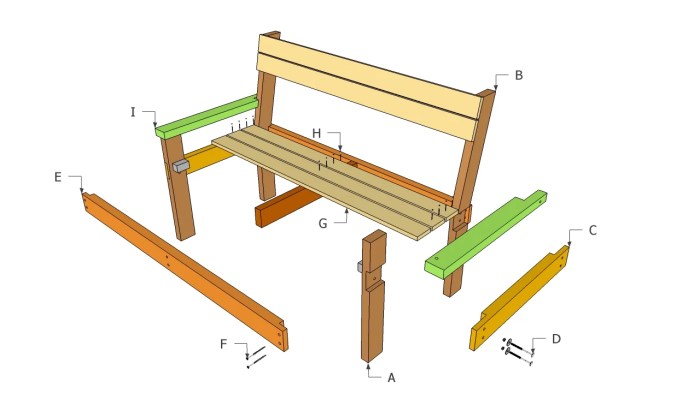

Building a Basic Woodworking Bench

Here’s a step-by-step guide for building a basic woodworking bench:

- Design and Plan: Determine the size and features of your bench. Draw a plan to scale, including dimensions and materials.

- Cut Lumber: Using your plan, cut the lumber to the required dimensions.

- Assemble the Legs: Cut and join the legs to form the bench’s base. Use strong joints like mortise and tenon or dado joints.

- Assemble the Top: Cut and join the top pieces of the bench. Consider using a dado joint to create a flush surface.

- Attach the Top to the Legs: Securely attach the top to the legs using screws, bolts, or dowels.

- Add Braces: Include braces for added stability and strength.

- Sanding and Finishing: Smooth the surface of the bench with sandpaper. Apply a finish of your choice, such as paint, stain, or varnish.

Safety Precautions for Woodworking Benches

Woodworking benches are essential tools for any woodworker, but they can also be dangerous if not used properly. It’s crucial to prioritize safety when building and using a woodworking bench to prevent injuries and ensure a safe and enjoyable woodworking experience. This section will Artikel important safety precautions, the importance of using proper safety gear, and tips for setting up a safe and organized woodworking workspace.

Using Proper Safety Gear

Wearing the appropriate safety gear is essential when working with woodworking tools and machinery.

- Eye Protection: Always wear safety glasses or goggles to protect your eyes from flying debris, wood chips, and dust. Consider using a face shield for added protection, especially when working with power tools.

- Hearing Protection: Use earplugs or earmuffs when operating noisy equipment like power saws or sanders. Prolonged exposure to loud noise can cause hearing damage.

- Gloves: Wear gloves to protect your hands from splinters, sharp edges, and rough surfaces. Choose gloves that offer a good grip and dexterity.

- Dust Mask: Wood dust can be harmful to your respiratory system. Wear a dust mask, preferably an N95 respirator, when sanding, cutting, or working with wood that generates dust.

- Respiratory Protection: In addition to a dust mask, consider using a respirator when working with certain types of wood, such as hardwoods, which can release harmful chemicals.

Setting Up a Safe and Organized Workspace, Woodworking plans benches

A well-organized and safe workspace is crucial for preventing accidents and ensuring efficient workflow.

- Clear Workspace: Keep your workspace clear of clutter and obstacles. Remove any unnecessary items, tools, or materials that could cause tripping hazards.

- Proper Lighting: Ensure adequate lighting in your workspace. Good lighting helps you see clearly, reducing the risk of accidents.

- Secure Tools: Store your tools properly and securely to prevent them from falling or being mishandled. Consider using tool organizers, pegboards, or tool chests.

- Fire Extinguisher: Have a fire extinguisher readily available in case of a fire. Ensure you know how to use it properly.

- First Aid Kit: Keep a well-stocked first aid kit on hand for treating minor injuries.

Maintenance and Care of a Woodworking Bench

Just like any valuable tool, your woodworking bench needs regular care to keep it in top condition. A well-maintained bench will provide years of reliable service and remain safe to use. Here’s how to ensure your bench stays in top shape.

Cleaning and Protecting the Bench

Regular cleaning helps prevent dirt, dust, and grime from accumulating on the bench’s surface. These substances can dull the finish and make it difficult to work on the bench.

- Start by removing any debris or sawdust with a brush or vacuum cleaner.

- Then, wipe the surface with a damp cloth. Avoid using harsh chemicals or abrasive cleaners, as they can damage the finish.

- After cleaning, apply a wood conditioner or sealant to protect the wood from moisture and wear. This will help maintain the bench’s appearance and extend its lifespan.

Repairing Common Damage

Even with regular maintenance, your bench might experience some damage over time. Here are some common repairs:

- Scratches and Dents: For minor scratches, use a wood filler to match the bench’s color. For deeper dents, you can use a wood putty or epoxy.

- Loose Joints: If a joint becomes loose, tighten the screws or bolts. If the wood has split, you can use wood glue and clamps to re-join the pieces.

- Cracked or Broken Legs: If a leg is cracked or broken, you can use a wood glue and clamps to re-join the pieces. If the damage is severe, you may need to replace the leg entirely.

Woodworking Bench Accessories and Upgrades

A well-equipped woodworking bench is more than just a sturdy surface; it’s a system designed to hold, support, and manipulate your workpieces with precision. Accessories play a crucial role in enhancing the functionality of your bench, allowing you to tackle a wider range of projects with greater efficiency and safety.

Bench Dogs

Bench dogs are essential accessories for woodworking benches, providing secure clamping points for workpieces. They are typically made of metal or hardwood and come in various sizes and configurations to accommodate different tasks. Bench dogs are inserted into holes drilled into the benchtop, creating a solid anchor for clamping.

Choosing and Installing Bench Dogs

- Material: Choose bench dogs made from durable materials like steel or hardwood, ensuring they can withstand the stresses of woodworking.

- Size: Consider the size of the workpieces you’ll be using. Larger projects may require larger bench dogs for greater stability.

- Configuration: Bench dogs come in various configurations, such as single-ended, double-ended, or with built-in stops. Choose the configuration that best suits your needs.

- Installation: Drill holes in the benchtop according to the manufacturer’s instructions. Ensure the holes are positioned strategically for optimal clamping.

Holdfasts

Holdfasts are another vital accessory for woodworking benches, providing a secure way to clamp workpieces to the benchtop. They are typically made of metal and consist of a hook that is driven into a pre-drilled hole in the benchtop.

Choosing and Installing Holdfasts

- Size: Holdfasts come in various sizes to accommodate different thicknesses of workpieces. Choose the size that provides a secure grip without damaging the wood.

- Material: Opt for holdfasts made from durable metal like steel or iron, ensuring they can withstand the stresses of woodworking.

- Installation: Drill holes in the benchtop according to the manufacturer’s instructions. Ensure the holes are positioned strategically for optimal clamping.

Planing Stops

Planing stops are useful accessories that help to prevent your workpiece from sliding while planing or sanding. They are typically made of metal or hardwood and are clamped to the benchtop, creating a barrier for your workpiece.

Choosing and Installing Planing Stops

- Material: Choose planing stops made from durable materials like steel or hardwood, ensuring they can withstand the stresses of woodworking.

- Size: Consider the size of the workpieces you’ll be using. Choose planing stops that provide adequate support without obstructing the work area.

- Installation: Clamp the planing stops securely to the benchtop, ensuring they are positioned strategically for optimal support.

Other Useful Accessories

In addition to bench dogs, holdfasts, and planing stops, other accessories can enhance the functionality of your woodworking bench:

- Vise: A vise is a crucial accessory for woodworking benches, providing a secure way to hold and manipulate workpieces. It is essential for tasks such as cutting, shaping, and drilling.

- Tool Tray: A tool tray attached to the benchtop provides a convenient place to store tools, keeping them within easy reach and organized.

- Outfeed Table: An outfeed table placed next to the bench provides a stable surface for supporting long workpieces as they are pushed through power tools.

- Dust Collection System: A dust collection system attached to the bench helps to keep the work area clean and safe by removing sawdust and debris.

Inspiration and Design Ideas for Woodworking Benches

A woodworking bench is more than just a piece of furniture; it’s a crucial element in your workshop, a foundation for your projects, and a reflection of your personal style. The design of your bench should be tailored to your needs and preferences, taking into account the types of projects you’ll be working on and the space you have available.

Bench Styles and Designs

There are many different styles of woodworking benches, each with its own unique features and benefits. Consider the following styles when planning your bench:

- Traditional Bench: This classic design features a sturdy, solid top with a vise and often includes a leg vise. It’s ideal for a wide range of woodworking tasks.

- Modern Bench: Modern benches often prioritize simplicity and functionality. They may have a minimalist design with a focus on clean lines and lightweight construction.

- Portable Bench: These benches are designed for mobility and can be easily transported to different locations. They’re great for outdoor projects or for those with limited space.

- Specialty Bench: There are also benches designed for specific tasks, such as metalworking, jewelry making, or carving. These benches often have features that are tailored to the specific requirements of the task.

Designing a Bench for Specific Tasks

A well-designed bench should be tailored to the types of projects you’ll be working on. For example, a bench for woodworking may have a wider top and a more robust vise, while a bench for metalworking may have a heavy-duty base and a different type of vise.

- Woodworking: A woodworking bench should have a wide, flat top to provide ample work surface. A sturdy vise is essential for holding workpieces securely. Consider including a leg vise for clamping large pieces.

- Metalworking: A metalworking bench needs to be strong and stable to withstand the forces of hammering and bending metal. A heavy-duty base and a vise that can handle metal are essential. A dedicated anvil or a metalworking vise is often included.

- General Crafts: A bench for general crafts can be more versatile. It may have a smaller footprint and a less robust vise. Consider features like shelves or drawers for storing tools and materials.

Personal Preferences and Needs

The most important aspect of designing a woodworking bench is to consider your own personal preferences and needs. Ask yourself the following questions:

- What types of projects will you be working on?

- What size and shape bench is best for your workspace?

- What features are essential for you, such as a vise, tool holders, or storage?

- What materials and style do you prefer?

By carefully considering your needs and preferences, you can design a woodworking bench that is both functional and aesthetically pleasing.

Final Summary

With the right woodworking plans, tools, and a little dedication, you can build a woodworking bench that will enhance your craft and inspire countless projects. Remember to prioritize safety, choose high-quality materials, and don’t be afraid to experiment with different designs. Building a woodworking bench is a rewarding journey that combines skill, creativity, and a touch of craftsmanship, leaving you with a piece of furniture that reflects your passion for woodworking.

FAQs: Woodworking Plans Benches

What are the benefits of using woodworking plans for building a bench?

Using woodworking plans provides detailed instructions, precise measurements, and clear visualizations, ensuring a successful outcome and minimizing errors.

What are some essential tools for building a woodworking bench?

Essential tools include a saw, drill, sander, measuring tape, clamps, and a variety of hand tools.

What safety precautions should I take when building a woodworking bench?

Always wear eye protection, gloves, and a dust mask. Use proper lifting techniques, and ensure your workspace is well-ventilated.