Woodworking plans glider – the phrase evokes images of leisurely afternoons spent swaying gently on a handcrafted masterpiece. Building your own glider isn’t just about creating a piece of furniture; it’s about crafting a sanctuary of relaxation, a testament to your woodworking skills, and a unique addition to your outdoor space.

This guide delves into the world of glider woodworking plans, covering everything from choosing the right design to mastering the construction process. Whether you’re a seasoned woodworker or a curious beginner, we’ll provide the knowledge and resources you need to build a glider that’s both beautiful and functional.

Introduction to Glider Woodworking Plans

There’s something undeniably charming about a glider. It evokes a sense of tranquility, a gentle rocking motion that invites relaxation and contemplation. Perhaps it’s the nostalgic feeling of being gently swayed as a child, or the simple pleasure of swaying back and forth while enjoying a cup of coffee on a warm summer day. Whatever the reason, the allure of a glider is undeniable, and building one yourself from woodworking plans can be a rewarding and fulfilling experience.

Woodworking plans for gliders offer a wealth of benefits. They provide detailed instructions, precise measurements, and clear diagrams, ensuring a successful build even for beginners. With the right plans, you can create a glider that perfectly suits your style, space, and needs.

Types of Gliders

Woodworking plans offer a wide range of glider styles to choose from, catering to various preferences and needs.

- Porch Swing Gliders: These gliders are designed for outdoor use, typically featuring a wide, comfortable seat and a sturdy frame to withstand the elements. They are ideal for relaxing on the porch, enjoying the fresh air, and soaking up the sunshine.

- Rocking Gliders: Combining the gentle rocking motion of a glider with the soothing rhythm of a rocking chair, these gliders offer a unique and calming experience. They are often found in living rooms, bedrooms, or sunrooms, providing a comfortable spot to unwind after a long day.

- Indoor Gliders: These gliders are specifically designed for indoor use, often featuring sleek and stylish designs that complement a variety of home decor styles. They can be placed in any room, adding a touch of elegance and comfort.

- Children’s Gliders: Smaller and lighter than adult gliders, these models are perfect for children’s playrooms or bedrooms. They offer a fun and safe way for kids to enjoy the gentle rocking motion.

Choosing the Right Glider Plans

Building a glider is a rewarding project, but choosing the right plans is crucial for a successful outcome. Consider factors like your woodworking skills, the desired size and style of the glider, and the materials you want to use.

Types of Glider Plans

The availability of glider plans varies widely, ranging from free plans available online to paid plans offered by professional designers. Here’s a breakdown of different plan types:

- Free Plans: These plans are often available on websites dedicated to woodworking or DIY projects. They can be a great starting point for beginners, but they may lack detailed instructions or professional design.

- Paid Plans: Paid plans are typically more comprehensive and detailed, often offering professional-quality designs, detailed material lists, cut lists, and assembly instructions.

- Beginner-Friendly Plans: These plans are designed for those new to woodworking and often include simplified instructions and clear diagrams.

- Advanced Plans: These plans are geared towards experienced woodworkers and may involve more complex designs, intricate joinery, and specialized tools.

Plan Specifications

Understanding the plan’s specifications is essential before you start building. Here are some key elements to review:

- Materials List: This list Artikels the specific types and quantities of wood, hardware, and other materials needed for the project.

- Cut List: The cut list provides detailed dimensions and cuts for each piece of wood, ensuring accuracy and consistency.

- Assembly Instructions: Clear and detailed instructions are crucial for successful assembly, guiding you through each step of the process.

- Diagrams and Drawings: Plans often include diagrams and drawings to visualize the design and assembly process.

Materials and Tools for Glider Construction: Woodworking Plans Glider

Building a glider requires careful selection of materials and tools to ensure a sturdy and comfortable final product. The right materials and tools will make the process smoother and lead to a high-quality glider.

Common Materials for Glider Construction

The materials used in glider construction vary depending on the design and desired level of complexity. However, some common materials are essential for most glider projects.

Want to build a rocking glider for your porch? Woodworking plans for a glider can be a fun project. If you’re looking for some inspiration, check out cool woodworking plans for all sorts of projects. Once you’ve got your design, you can start planning out your glider and get those tools ready!

- Wood: Hardwoods like oak, maple, cherry, or walnut are commonly used for glider construction. These woods are durable, strong, and offer a beautiful finish. Softwoods like pine or cedar can be used for less demanding parts of the glider.

- Plywood: Plywood is a versatile material that can be used for the seat, back, and other structural components. It offers good strength-to-weight ratio and is readily available in various thicknesses.

- Hardware: This includes screws, bolts, nuts, washers, hinges, and other fasteners. Select high-quality hardware that is appropriate for the weight and stresses the glider will experience.

- Finishing Materials: This includes wood stains, paints, varnishes, and sealants. These materials protect the wood from damage and enhance its appearance. Choose finishing materials that are durable and compatible with the wood type.

- Foam and Fabric: For added comfort, you can use foam padding and fabric upholstery for the seat and back of the glider.

Essential Tools for Glider Construction

A range of tools are necessary for building a glider, from basic hand tools to power tools. Here are some essential tools for a successful project:

- Saws: A circular saw, jigsaw, and hand saw are essential for cutting wood to size. A miter saw can be helpful for making precise cuts.

- Drills: A cordless drill with various drill bits is necessary for drilling pilot holes and attaching hardware. A drill press can provide greater accuracy for drilling holes.

- Sanding Tools: A random orbit sander, belt sander, and hand sanding blocks are useful for smoothing surfaces and preparing them for finishing.

- Clamps: Various clamps are essential for holding wood pieces together during assembly and for gluing joints.

- Measuring Tools: A tape measure, ruler, and combination square are essential for accurate measurements.

- Other Tools: A hammer, screwdrivers, chisels, and a level are also necessary for various tasks during construction.

Sourcing High-Quality Materials and Tools, Woodworking plans glider

The quality of materials and tools used in glider construction directly affects the final product’s durability and longevity. Here are some tips for sourcing high-quality materials and tools:

- Local Lumberyards: Visit local lumberyards to inspect wood quality and get expert advice on selecting appropriate species for your project. They can also provide information on the wood’s drying process and stability.

- Online Retailers: Many online retailers offer a wide range of woodworking materials and tools. Check customer reviews and compare prices before purchasing.

- Specialty Tool Stores: Visit specialty tool stores for expert advice on choosing high-quality tools. They can help you find tools suitable for your skill level and project requirements.

- Used Tool Markets: If you’re on a budget, consider purchasing used tools from reputable sources. Inspect the tools carefully for signs of wear and tear before purchasing.

Step-by-Step Glider Construction Guide

Now that you have your plans and materials ready, let’s get started on building your glider. This step-by-step guide will walk you through the process, from cutting the wood to finishing the project. Remember to take your time and enjoy the process.

Cutting the Wood

Cutting the wood accurately is essential for a well-built glider. The plans will provide you with detailed dimensions for each piece of wood. Use a sharp saw, such as a circular saw or table saw, to make precise cuts. Ensure that you use a straight edge or measuring tape to guide your cuts. You can use a miter saw for making precise angle cuts.

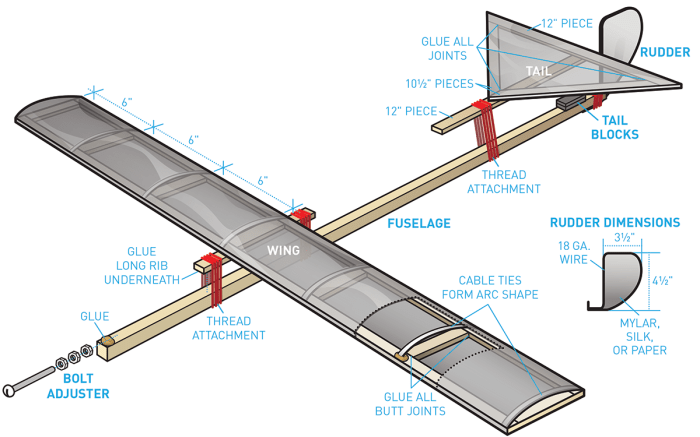

Assembling the Glider

After cutting the wood, you will need to assemble the glider. The plans will provide you with instructions and diagrams on how to join the pieces together. Common joinery methods used in glider construction include:

- Pocket holes: Pocket holes are drilled into the end of one piece of wood and are connected to another piece of wood using pocket hole screws. They provide a strong and hidden joint.

- Mortise and tenon: Mortise and tenon joints are a traditional joinery method that involves cutting a rectangular hole (mortise) in one piece of wood and a corresponding projection (tenon) on another piece. This method provides a strong and durable joint.

- Dowels: Dowels are small wooden pins that are used to connect two pieces of wood. They are inserted into pre-drilled holes and provide a strong and simple joint.

- Glue: Wood glue is an essential component in most joinery methods. Apply glue to the mating surfaces of the pieces you are joining.

Sanding the Glider

Sanding is an important step in achieving a smooth and even finish. Start with a coarse-grit sandpaper and gradually progress to finer grits. This will remove any rough edges and imperfections. Sand all surfaces of the glider, paying attention to corners and edges.

Finishing the Glider

The final step is to finish the glider. This involves applying a protective coating, such as paint, stain, or varnish. Paint provides a durable and colorful finish. Stain enhances the natural beauty of the wood, while varnish provides a clear protective layer.

- Paint: Choose a paint that is suitable for outdoor use and is resistant to moisture and UV rays.

- Stain: Apply stain evenly to the wood using a brush or cloth. Allow the stain to dry completely before applying a top coat.

- Varnish: Varnish is a clear protective coating that provides a glossy or satin finish. Apply varnish in thin coats, allowing each coat to dry completely before applying the next.

Safety Considerations in Glider Building

Building a glider requires using power tools and handling sharp objects. It is essential to prioritize safety to prevent injuries and ensure a successful project. By taking the necessary precautions, you can enjoy the woodworking process without putting yourself at risk.

Protective Gear

Wearing appropriate protective gear is crucial during the woodworking process. This gear acts as a barrier between you and potential hazards, minimizing the risk of injuries.

- Eye Protection: Always wear safety glasses or goggles to protect your eyes from flying debris, sawdust, and wood chips. This is especially important when using power tools like saws, sanders, and routers. Consider using a face shield for additional protection from larger particles.

- Hearing Protection: Power tools can generate significant noise that can damage your hearing over time. Use earplugs or earmuffs to reduce noise levels and protect your hearing. Remember that prolonged exposure to loud noises can cause permanent hearing loss.

- Respiratory Protection: Woodworking produces dust and fumes that can irritate your respiratory system. Use a dust mask or respirator to filter out these particles and prevent them from entering your lungs. Choose a mask or respirator that is appropriate for the type of wood you are working with. For example, a respirator with a particulate filter is suitable for general woodworking, while a respirator with a gas cartridge is necessary when working with certain types of wood, such as plywood, which may contain formaldehyde.

- Gloves: Wearing gloves protects your hands from splinters, cuts, and other injuries. Choose gloves that provide a good grip and are comfortable to wear. Consider using cut-resistant gloves when handling sharp tools like chisels and knives.

- Work Boots: Sturdy work boots with steel toes protect your feet from falling objects and provide a stable base for standing. Look for boots with slip-resistant soles to prevent falls on slippery surfaces.

Tool Safety

Using tools safely is paramount in woodworking. Each tool has its own set of potential hazards, so it is crucial to understand and follow safety guidelines for each one.

- Power Tools: Power tools require extra caution due to their potential for serious injury. Always use tools according to the manufacturer’s instructions. Inspect tools regularly for damage and ensure they are properly maintained. Never operate a tool with a damaged cord or plug. Always disconnect power tools before making adjustments or cleaning them. Use clamps or workbenches to secure the workpiece to prevent kickback. Avoid wearing loose clothing or jewelry that could get caught in moving parts. Never use a power tool if you are tired or under the influence of drugs or alcohol. For example, when using a table saw, ensure the blade is properly adjusted, and use a push stick to guide the wood safely. Always keep your fingers away from the blade path and never reach over the blade.

- Hand Tools: While hand tools may seem less dangerous than power tools, they can still cause injuries if used incorrectly. Always use sharp tools and keep them clean and in good working order. Use a cutting board to protect your work surface and prevent damage to your tools. Never use a tool for a purpose it was not intended for. For example, when using a chisel, always use a mallet or hammer to strike it, never your hand. Hold the chisel securely and keep your fingers away from the cutting edge.

Workspace Safety

A safe and organized workspace is essential for efficient and accident-free woodworking.

- Clear Work Area: Keep your workspace free of clutter and debris. This will help you avoid tripping hazards and ensure you have enough room to work safely. Regularly clean up sawdust and other debris to prevent fires and maintain a safe environment.

- Adequate Lighting: Ensure your workspace has adequate lighting to prevent eye strain and allow you to see clearly. Use overhead lighting and task lighting to illuminate your work area. Poor lighting can increase the risk of accidents.

- Secure Workbench: Use a sturdy workbench that is stable and secure. This will provide a solid base for your work and prevent tools from falling or tipping over. Ensure your workbench has a vise or clamps to hold your workpieces securely in place.

- Fire Extinguisher: Keep a fire extinguisher readily available in your workspace. Woodworking dust is flammable, and a fire can start quickly. Know how to use a fire extinguisher and practice your skills regularly. Install smoke detectors in your workspace to provide early warning of a fire.

- First Aid Kit: Have a first aid kit readily available in your workspace. This should include bandages, antiseptic wipes, and pain relievers. Know how to provide basic first aid in case of an injury.

Finishing and Refinishing a Glider

The final step in building a glider is applying a finish. A good finish protects the wood, enhances its appearance, and adds durability. There are many different finishing techniques, each with its own advantages and disadvantages.

Sanding

Sanding is essential for preparing the wood for any finish. It creates a smooth surface and removes any imperfections. Start with coarse-grit sandpaper to remove rough spots, and gradually progress to finer grits for a smooth finish. Use a sanding block or orbital sander for even results. Sanding with the grain of the wood will produce the best results. You can also use sanding sealer to fill in pores and create a smoother surface.

Staining

Staining adds color and depth to the wood. There are many different types of stains available, including oil-based, water-based, and gel stains. Oil-based stains are known for their deep penetration and rich color, while water-based stains are easier to clean up. Gel stains are thicker and provide more coverage. Apply stain with a brush, cloth, or sponge, and let it dry completely before applying a topcoat.

Painting

Painting is a great way to cover the wood and give it a new look. You can use any type of paint, but latex paints are a good choice for outdoor furniture. Apply paint with a brush, roller, or spray gun. Make sure to apply thin coats and allow each coat to dry completely before applying the next.

Sealing

Sealing protects the wood from moisture, UV rays, and other elements. There are many different types of sealers available, including polyurethane, varnish, and lacquer. Polyurethane is a durable and long-lasting sealant that provides good protection from moisture and UV rays. Varnish is a clear sealant that enhances the natural beauty of the wood. Lacquer is a fast-drying sealant that is often used for furniture. Apply sealer with a brush, roller, or spray gun. Make sure to apply thin coats and allow each coat to dry completely before applying the next.

Finishing Tips

- Always wear a respirator when sanding, staining, painting, or sealing. Wood dust and fumes can be harmful to your health.

- Work in a well-ventilated area. This will help to prevent fumes from building up.

- Protect your work surface with drop cloths or plastic sheeting.

- Clean up any spills immediately. Some finishes can be difficult to remove once they have dried.

- Let the finish dry completely before using the glider. This will help to prevent damage to the finish.

Maintaining and Refinishing a Glider

Proper maintenance will help to keep your glider looking its best for years to come. Here are a few tips:

- Clean the glider regularly with a damp cloth. Avoid using harsh chemicals or abrasive cleaners.

- Protect the glider from the elements. Store it indoors or cover it with a tarp when not in use.

- Refinish the glider as needed. This will help to restore its appearance and protect the wood.

Glider Design Ideas and Variations

Once you’ve chosen your glider plans, it’s time to get creative! There are endless possibilities for customizing your glider to perfectly match your style and needs. This section will explore different design elements, unique glider designs, and encourage you to personalize your project.

Backrests and Armrests

The backrest and armrests are essential for comfort and support. Consider these options:

- Height: A taller backrest provides more head and neck support, while a shorter backrest offers a more open feel.

- Shape: Curved backrests provide ergonomic support, while straight backrests offer a more classic look.

- Width: Wider armrests provide more space for resting your arms, while narrower armrests offer a more compact design.

- Materials: Armrests can be made from wood, metal, or upholstered in fabric for added comfort and style.

Cushions

Cushions are an integral part of a glider’s comfort and style.

- Size and Shape: Cushions come in various sizes and shapes to fit different glider designs. You can choose from square, rectangular, or curved cushions to complement your backrest and armrests.

- Fillings: Common cushion fillings include foam, down, and fiberfill. Choose a filling that provides the desired level of firmness and support.

- Fabric: The fabric for your cushions can be chosen to match your glider’s style and your home decor. Consider durability, stain resistance, and comfort when selecting a fabric.

Unique Glider Designs

Here are some unique design ideas to inspire your glider project:

- Curved Backs: Curved backrests provide excellent ergonomic support and create a flowing, elegant look.

- Intricate Carvings: Add a touch of artistry with intricate carvings on the backrest, armrests, or base of your glider. This can be a beautiful way to showcase your woodworking skills and create a unique piece.

- Custom Finishes: Explore different wood stains, paints, and finishes to achieve the desired look for your glider. You can create a rustic, modern, or elegant finish depending on your preferences.

Resources for Glider Woodworking

Building a glider is a rewarding project, and finding the right resources can make the process smoother and more enjoyable. From detailed plans to expert advice, there’s a wealth of information available to help you craft a beautiful and functional glider.

Online Resources for Glider Plans

There are numerous online resources offering glider plans, covering a wide range of styles and complexities.

- Woodworking Plans Websites: Websites like Woodworking for Mere Mortals, Ana White, and The Wood Whisperer offer a variety of free and paid plans for gliders. These websites often include detailed instructions, cut lists, and material recommendations.

- Online Marketplaces: Platforms like Etsy and eBay offer a wide selection of downloadable glider plans from independent designers and woodworking enthusiasts. You can find both basic and elaborate designs, catering to different skill levels.

- Specialty Glider Plan Providers: Some websites specialize exclusively in glider plans, offering a curated selection of designs and resources. These websites often provide additional support and guidance for builders.

Materials and Tools for Glider Construction

Finding the right materials and tools is crucial for successful glider construction.

- Lumber: Select high-quality hardwood lumber, such as oak, maple, or cherry, for durability and aesthetics. Softwoods like pine can be used for less demanding parts.

- Hardware: Essential hardware includes screws, bolts, nuts, washers, and dowels. Choose high-quality hardware for strength and longevity.

- Woodworking Tools: Basic woodworking tools like a saw, drill, sander, and measuring tools are essential. Depending on the complexity of the plan, you may need additional tools like a router, table saw, or jointer.

- Finishing Supplies: Choose appropriate wood finishes, such as paint, stain, or varnish, based on the desired look and protection level.

Woodworking Communities and Forums

Connecting with other woodworking enthusiasts can provide invaluable support and inspiration.

- Online Forums: Websites like Lumberjocks, Woodworking Talk, and Reddit’s r/Woodworking offer active communities where you can ask questions, share your projects, and learn from experienced woodworkers.

- Local Woodworking Clubs: Joining a local woodworking club provides opportunities to meet fellow enthusiasts, attend workshops, and access shared resources.

Books, Articles, and Videos on Glider Construction

There are numerous books, articles, and videos available to enhance your woodworking skills and guide you through glider construction.

- Books: Books like “The Complete Illustrated Guide to Woodworking” by Bob Vila and “The Woodworker’s Bible” by Taunton Press provide comprehensive information on woodworking techniques and projects, including glider construction.

- Articles: Websites like Popular Woodworking and Fine Woodworking offer in-depth articles on various woodworking topics, including glider construction techniques and design ideas.

- Videos: Online platforms like YouTube and Skillshare offer numerous woodworking tutorials and project walkthroughs, including glider construction guides.

Closure

From selecting the perfect plans to applying the final finishing touches, building a glider from scratch is a rewarding journey. With careful planning, patience, and a dash of creativity, you can transform your woodworking dreams into a reality that will bring joy for years to come. So, gather your tools, embrace the process, and enjoy the satisfaction of creating a custom glider that’s uniquely yours.

Top FAQs

What type of wood is best for building a glider?

Hardwoods like oak, maple, and cherry are known for their durability and strength, making them excellent choices for glider construction. However, softer woods like pine or cedar can be used for less demanding projects.

How long does it take to build a glider from plans?

The time required to build a glider varies depending on the complexity of the plans, your skill level, and the time you dedicate to the project. Expect to spend several hours to a few days on construction.

What safety precautions should I take when building a glider?

Always wear safety glasses, ear protection, and a dust mask when working with wood. Use sharp tools carefully and follow the manufacturer’s instructions for all power tools.