Woodworking plans tables offer a gateway to crafting stunning, personalized furniture pieces. Whether you’re a seasoned woodworker or just starting out, these detailed blueprints provide a roadmap to success, guiding you through every step of the process. From classic dining tables to charming coffee tables and elegant end tables, woodworking plans empower you to build furniture that reflects your unique style and skill level.

The beauty of woodworking plans lies in their ability to demystify the construction process. They provide precise measurements, cutting diagrams, and assembly instructions, ensuring accuracy and minimizing the risk of costly mistakes. This level of detail allows you to create furniture that is not only functional but also a testament to your craftsmanship.

Essential Woodworking Tools and Techniques: Woodworking Plans Tables

Building a table requires a combination of tools and techniques that allow you to accurately cut, shape, and join pieces of wood. Understanding the basics of woodworking tools and techniques will help you build a sturdy and beautiful table.

Essential Woodworking Tools

A well-equipped workshop will have a range of tools, both hand and power, to facilitate various tasks. Here’s a table outlining essential tools for table building:

| Tool Name | Purpose | Example Brands/Models |

|---|---|---|

| Measuring Tape | Accurate measurement of wood pieces. | Stanley FatMax, Lufkin, Milwaukee |

| Combination Square | Checking for squareness and marking precise angles. | Starrett, Swanson, Empire |

| Hand Saw | Cutting wood to length and shape. | Stanley, DeWalt, Irwin |

| Circular Saw | Making precise cuts, crosscuts, and rip cuts. | DeWalt, Makita, Bosch |

| Jig Saw | Cutting intricate shapes and curves. | Bosch, Ryobi, Skil |

| Router | Shaping edges, creating grooves, and making decorative details. | DeWalt, Makita, Festool |

| Drill | Drilling holes for fasteners and creating pilot holes. | DeWalt, Bosch, Ryobi |

| Clamps | Securing wood pieces together for assembly and gluing. | Bessey, Irwin, Jorgensen |

| Sandpaper | Smoothing surfaces and removing imperfections. | 3M, Norton, Klingspor |

| Wood Glue | Joining wood pieces permanently. | Titebond, Elmer’s, Gorilla Glue |

| Finish (e.g., Stain, Polyurethane) | Protecting and enhancing the appearance of the wood. | Minwax, Varathane, Rust-Oleum |

Common Woodworking Techniques

Woodworking techniques are the methods used to manipulate wood and create desired shapes, joints, and finishes.

- Cutting: Cutting wood involves using various tools like saws, routers, and jigsaws to create precise cuts and shapes.

- Crosscut: Cutting across the grain of the wood.

- Rip Cut: Cutting along the grain of the wood.

- Mitering: Cutting an angle at the end of a piece of wood for joining at a specific angle.

- Dado Cut: A groove cut across the width of a piece of wood.

- Rabbet Cut: A groove cut along the edge of a piece of wood.

- Joining: Joining wood pieces together involves creating strong and durable connections.

- Butt Joint: A simple joint where two pieces of wood are butted together end-to-end.

- Lap Joint: A joint where one piece of wood overlaps another.

- Mortise and Tenon Joint: A strong joint where a rectangular hole (mortise) is cut in one piece of wood and a corresponding projection (tenon) is cut on the other piece.

- Dovetail Joint: A strong and decorative joint that interlocks two pieces of wood using angled cuts.

- Finishing: Finishing involves applying a protective and aesthetic layer to the wood.

- Sanding: Smoothing the surface of the wood to remove imperfections and prepare it for finishing.

- Staining: Adding color to the wood while preserving its natural grain.

- Sealing: Protecting the wood from moisture and other elements.

- Polishing: Enhancing the shine and smoothness of the wood.

- Hardwoods come from deciduous trees, which lose their leaves in the fall. They generally have a more complex grain pattern and are often denser and harder than softwoods. Examples include oak, maple, cherry, walnut, and mahogany.

- Softwoods come from coniferous trees, which bear cones and retain their needles year-round. They typically have a simpler grain pattern and are softer and less dense than hardwoods. Examples include pine, fir, cedar, and spruce.

- Engineered woods are created by combining wood fibers, veneers, or wood particles with adhesives. They offer various advantages, such as stability, affordability, and resistance to warping. Examples include plywood, MDF (medium-density fiberboard), and particleboard.

- Hardness: Measured by the Janka scale, hardness indicates the wood’s resistance to dents and scratches. Hardwoods generally rank higher on the Janka scale than softwoods. A harder wood is better suited for high-traffic areas or surfaces that experience frequent use.

- For example, oak is a popular choice for tabletops due to its durability and resistance to wear and tear.

- Grain Pattern: The arrangement of wood fibers creates the grain pattern, which can vary significantly between species. Grain patterns add visual interest and contribute to the wood’s aesthetic appeal.

- For instance, cherry wood has a beautiful reddish-brown hue and a straight, even grain, while walnut wood features distinctive swirls and knots.

- Workability: This refers to how easily the wood can be cut, shaped, and sanded. Some woods are more challenging to work with than others due to their density, grain pattern, or tendency to splinter.

- Softwoods, like pine, are generally easier to work with than hardwoods, while hardwoods like maple can be more demanding.

- Durability: The durability of wood refers to its resistance to decay, insect infestation, and moisture damage. Some wood species are naturally more durable than others.

- For example, teak is known for its exceptional durability and resistance to rot, making it ideal for outdoor furniture.

- Aesthetics: The appearance of wood is a significant factor in table construction. Wood species offer a wide range of colors, grain patterns, and finishes, allowing for diverse aesthetic expressions.

- For instance, mahogany’s rich reddish-brown color and intricate grain patterns add elegance to table designs.

- Cost: The cost of wood varies widely depending on the species, availability, and quality. Hardwoods are generally more expensive than softwoods, while engineered woods offer a more affordable option.

- For example, pine is a budget-friendly option for table construction, while exotic hardwoods like ebony can be very expensive.

- Hardwoods:

- Oak: Durable, strong, and readily available. Offers a wide range of colors and grain patterns.

- Maple: Hard, dense, and known for its beautiful, even grain. Popular for tabletops and legs.

- Cherry: Beautiful reddish-brown color with a straight grain. Often used for tabletops and decorative elements.

- Walnut: Distinctive swirls and knots create a unique and elegant appearance. Popular for tabletops and legs.

- Mahogany: Rich reddish-brown color with a beautiful grain pattern. Often used for tabletops and legs.

- Softwoods:

- Pine: Affordable, lightweight, and easy to work with. Often used for table legs and frames.

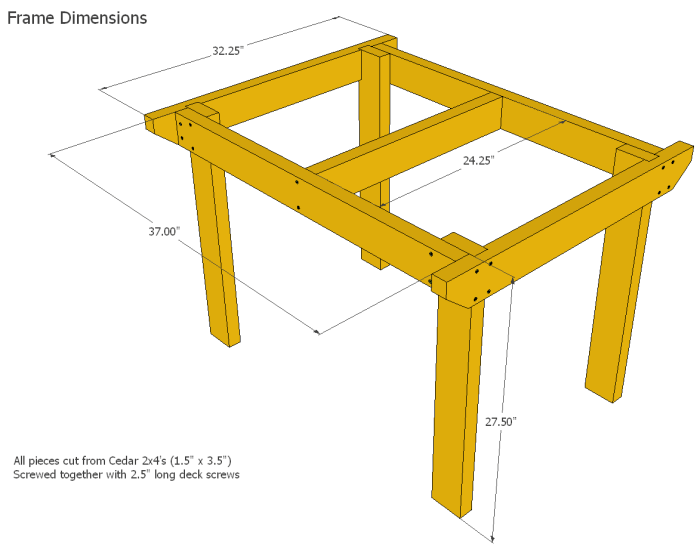

- Cedar: Aromatic, naturally insect-resistant, and known for its durability. Popular for outdoor tables.

- Spruce: Lightweight and strong, often used for table legs and frames.

- Engineered Woods:

- Plywood: Stable, durable, and less prone to warping than solid wood. Often used for tabletops and frames.

- MDF (Medium-Density Fiberboard): Smooth, consistent surface, and affordable. Often used for tabletops and drawer fronts.

- Particleboard: Affordable, but less durable than plywood or MDF. Often used for table legs and frames.

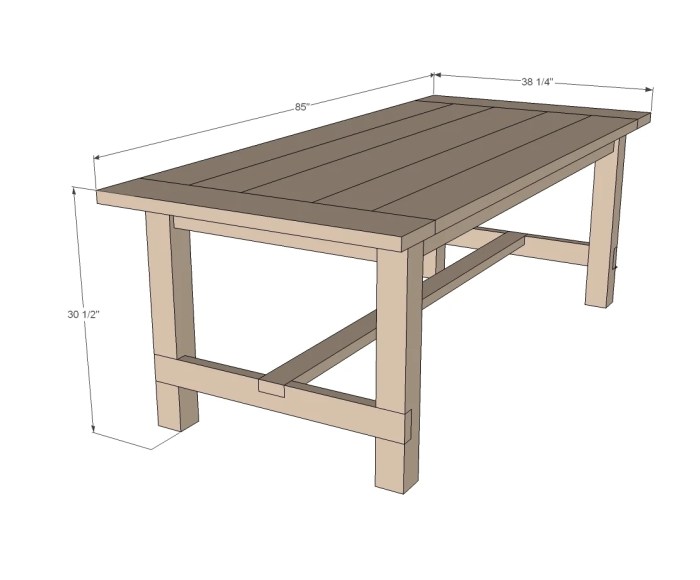

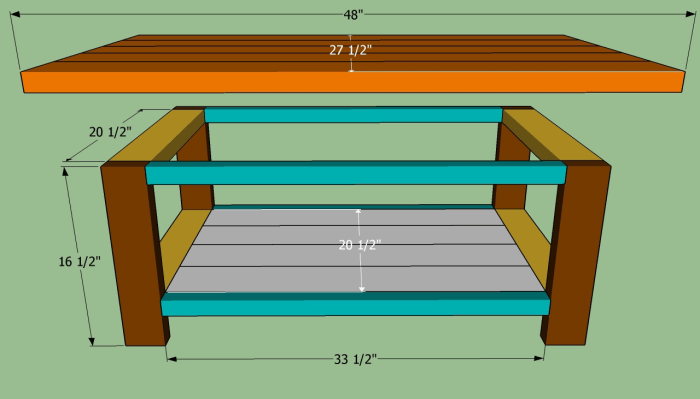

- Dimensions: The dimensions of your table will depend on its intended use and the space it will occupy. Consider the length, width, and height of the table. For example, a dining table should be large enough to comfortably seat all of your guests, while a coffee table should be smaller and lower to the ground.

- Shape: The shape of your table can significantly impact its look and functionality. Common table shapes include rectangular, square, round, oval, and even irregular shapes. Rectangular tables are practical for dining, while round tables encourage conversation and create a more intimate atmosphere.

- Style: The style of your table should complement your home’s décor and personal taste. Consider traditional, modern, rustic, or contemporary styles. A traditional table might feature intricate carvings and a dark wood finish, while a modern table might have a sleek design and a minimalist aesthetic.

- Functionality: Consider how you plan to use your table and design it accordingly. For example, a dining table might need to accommodate a large number of people, while a coffee table might need to have storage space for books and remotes.

- Purpose: What will the table be used for? This will determine the size, shape, and style of the table. A dining table needs to be large enough to seat all of your guests comfortably, while a coffee table needs to be small and low to the ground.

- Space: How much space do you have available? Measure the area where the table will be placed to ensure it fits properly. Also, consider the traffic flow around the table. For example, a large dining table in a small room might make it difficult to move around.

- Style: What style do you want the table to have? The style should complement the existing décor of the room. For example, a modern table might look out of place in a traditional dining room.

- Budget: How much are you willing to spend on the table? The cost of materials, tools, and labor will all factor into the overall budget.

- Sketch: A simple sketch can be made on paper or using a drawing program. Start by drawing the basic shape of the table and then add details such as the legs, top, and any other features. Use a ruler and pencil to ensure that your sketch is accurate.

- Digital Model: A digital model can be created using a computer-aided design (CAD) program. CAD programs allow you to create detailed 3D models of your table. This will help you visualize the finished product from all angles and make any necessary adjustments to the design.

- Use a sharp saw blade for clean, precise cuts.

- Clamp the wood securely to your work surface to prevent movement during cutting.

- Always wear safety glasses and a dust mask when cutting wood.

- If you are using a power saw, make sure that you are familiar with its operation and safety procedures.

- Start by assembling the table top. This may involve joining multiple pieces of wood together using glue and screws.

- Next, assemble the table legs. Again, this may involve joining multiple pieces of wood together using glue and screws.

- Finally, attach the table top to the legs. This is typically done using screws, bolts, or dowels.

- Sand the table. Start with a coarse grit sandpaper to remove any rough edges and smooth out the surface. Gradually progress to finer grits until the table is smooth and even.

- Apply a finish. There are many different types of wood finishes available, so choose one that suits your needs and preferences. Some popular finishes include oil, varnish, and polyurethane.

- Let the finish dry completely. This may take several hours or even days, depending on the type of finish you use.

- The table top is not level. This can be caused by uneven wood or improper assembly. To fix this, use a level to check the table top and adjust the legs accordingly. You can also use shims to level the table top.

- The table wobbles. This is often caused by loose joints or uneven legs. To fix this, tighten the screws or bolts that hold the table together. You can also use shims to level the legs.

- The finish is uneven. This can be caused by applying the finish too thickly or not sanding the table properly. To fix this, you can sand the table again and reapply the finish.

- Water-based stains are easy to apply and clean up, but they tend to raise the grain of the wood, requiring sanding before applying a topcoat.

- Oil-based stains penetrate deeper into the wood, providing a richer color and better protection. They are slower to dry and require mineral spirits for cleanup.

- Gel stains are thicker than water-based or oil-based stains and are ideal for achieving a more even color on porous woods like pine or oak. They also help to minimize blotching.

- Polyurethane is a durable and water-resistant finish that comes in both oil-based and water-based formulas. It provides excellent protection against scratches and spills, making it ideal for high-traffic areas.

- Lacquer is a hard, fast-drying finish that provides a high-gloss shine. It is often used on furniture and musical instruments.

- Varnish is a durable and versatile finish that offers a range of gloss levels. It can be used on both indoor and outdoor furniture.

- Wax is a natural finish that provides a soft, warm sheen. It is not as durable as other finishes but is easy to apply and maintain.

- Oil finishes, such as tung oil or Danish oil, penetrate deeply into the wood, enhancing its natural beauty. They are less durable than other finishes but offer a warm, natural look.

- Prepare the surface properly by sanding it smooth and removing any dust or debris. This will ensure that the finish adheres properly.

- Apply the finish in thin, even coats. Too much finish can lead to runs and drips.

- Allow each coat to dry completely before applying the next. This will prevent the finish from becoming cloudy or uneven.

- Sand lightly between coats to smooth out any imperfections and create a smooth, even finish.

- Use a high-quality brush or sprayer to apply the finish. This will help to ensure that the finish is applied evenly and without streaks.

- Use coasters and placemats to prevent scratches and stains.

- Clean spills immediately to prevent them from soaking into the wood.

- Avoid placing hot objects directly on the table. Use trivets or hot pads to protect the surface.

- Dust regularly to prevent the buildup of dust and dirt.

Understanding Wood Species and Properties

Choosing the right wood for your table project is crucial. Different wood species have distinct characteristics that influence the final outcome of your project. Understanding these properties will help you select the best wood for your needs and ensure a successful build.

Hardwoods, Softwoods, and Engineered Woods

The terms “hardwood” and “softwood” are somewhat misleading, as they don’t always reflect the actual hardness of the wood. They refer to the type of tree from which the wood is derived.

Characteristics of Wood Species

Wood species exhibit unique properties that make them suitable for specific applications.

Wood Species for Table Construction

Here are some popular wood species commonly used for table construction:

Designing Your Own Table

Creating a custom table gives you the freedom to design a piece that perfectly fits your needs and style. From choosing the perfect dimensions and shape to selecting the right wood and finish, the possibilities are endless.

Key Elements of Table Design

The key elements of table design include dimensions, shape, style, and functionality.

Designing a Table for a Specific Purpose and Space

To design a table that suits a specific purpose and space, consider the following:

Creating a Simple Sketch or Digital Model

Before you start building your table, it’s helpful to create a sketch or digital model. This will help you visualize the finished product and make any necessary adjustments to the design.

Building the Table

Now that you have your plans, tools, and materials, it’s time to bring your table design to life. Building a table from scratch is a rewarding experience, and with careful planning and execution, you can create a piece that will last for generations. This step-by-step guide will walk you through the process, from cutting the wood to applying the finishing touches.

Cutting the Wood

This is the first and arguably most crucial step. It’s essential to cut the wood accurately and precisely to ensure that your table will fit together properly.

Before you start cutting, double-check your measurements and make sure that you have all the necessary tools. You’ll need a saw, a measuring tape, a pencil, and a straight edge.

For accurate cuts, use a saw guide or a miter saw.

Always make your cuts slightly longer than the required dimensions. You can always trim the wood down later, but you can’t add wood back if you cut it too short.

Here are some additional tips for cutting the wood:

Assembling the Table

Now that your wood is cut, you can start assembling the table. The assembly process will vary depending on the design of your table, but the general steps are as follows:

Finishing the Table

Once the table is assembled, it’s time to give it a finishing touch. This will help protect the wood from damage and enhance its appearance.

Troubleshooting

Building a table can be challenging, and there are bound to be some bumps along the way. Here are some common problems that you may encounter and how to fix them:

Finishing Touches

The final step in your woodworking project is applying a finish. This step not only enhances the table’s appearance but also protects it from scratches, stains, and moisture. There are various finishes available, each with its unique properties and application methods. Choosing the right finish depends on the desired look, the wood species, and the level of protection required.

Staining Techniques, Woodworking plans tables

Staining is a process that adds color and depth to wood, enhancing its natural grain patterns. Different staining techniques can be used to achieve various effects.

Wood Finishes

Once you’ve stained the wood, you’ll need to apply a protective finish. These finishes come in various forms, each offering different levels of protection and aesthetics.

Choosing the Right Finish

Choosing the right finish depends on the desired look, the level of protection required, and the wood species. For example, a high-gloss polyurethane finish would be suitable for a dining table that needs to be durable and easy to clean. A wax finish would be a better choice for a coffee table that is used less frequently and needs a more natural look.

Achieving a Professional Finish

Here are some tips for achieving a professional-looking finish:

Protecting Your Table from Wear and Tear

Once your table is finished, you’ll want to take steps to protect it from wear and tear.

Final Wrap-Up

With the right plans, tools, and a bit of dedication, you can transform a simple set of instructions into a beautiful and functional piece of furniture. Whether you’re building a table for your home or as a gift for someone special, woodworking plans provide the foundation for creating lasting memories and cherished pieces that will be enjoyed for years to come. So, dive into the world of woodworking plans tables and embark on a journey of creative expression and rewarding craftsmanship.

Top FAQs

What are the different types of woodworking plans tables available?

You’ll find plans for various table styles, including dining tables, coffee tables, end tables, console tables, and more. Some plans even offer variations in size, shape, and design to suit your specific needs.

What level of woodworking experience is needed for building tables from plans?

Woodworking plans cater to a range of skill levels. Beginners can find simple plans with clear instructions, while experienced woodworkers can explore more complex projects with advanced techniques.

Where can I find free woodworking plans for tables?

Many online resources offer free woodworking plans. You can search for them on websites like Ana White, Woodworking for Mere Mortals, and various woodworking forums.

Woodworking plans tables are a lifesaver for any project, especially when you’re just starting out. They help you visualize the finished product and make sure you have all the necessary materials and tools. If you’re looking for a comprehensive collection of woodworking plans, you can check out downloadable woodworking plans to get started.

Once you have your plans, you can use your woodworking plans table to keep track of your progress and make sure you’re on the right track.