Woodworking shop plans are the blueprints to your next amazing project, whether you’re a seasoned craftsman or just starting out. They provide a roadmap for success, ensuring your project comes together smoothly and looks fantastic. These plans come in various levels of complexity, catering to beginners, intermediate builders, and even advanced woodworkers. Imagine the satisfaction of building a sturdy workbench, a beautiful coffee table, or even a custom bookshelf – all from carefully crafted plans.

This guide explores the world of woodworking shop plans, from understanding their essential elements to finding the perfect ones for your needs. We’ll delve into the different types of plans available, discuss safety considerations, and provide tips for using them effectively. Whether you’re a seasoned woodworker or a curious beginner, this guide will equip you with the knowledge and confidence to bring your woodworking dreams to life.

Introduction to Woodworking Shop Plans

Woodworking shop plans are essential for any woodworker, whether you’re a beginner or a seasoned professional. They provide a roadmap for your project, ensuring that you have all the necessary materials, tools, and knowledge to create a successful outcome.

These plans offer detailed instructions, diagrams, and measurements that guide you through every step of the building process, from cutting and shaping wood to assembling and finishing the piece.

Types of Woodworking Shop Plans

Woodworking shop plans are available in various formats and cater to different skill levels. Understanding the types of plans can help you choose the right ones for your needs.

- Beginner plans are designed for individuals with limited woodworking experience. They typically feature simple projects with clear instructions and step-by-step illustrations.

- Intermediate plans target woodworkers who have some experience and are ready to tackle more complex projects. These plans often involve more intricate designs and techniques.

- Advanced plans are meant for experienced woodworkers who are confident in their skills and want to take on challenging projects. These plans may require specialized tools and techniques.

Common Woodworking Projects Using Shop Plans

Woodworking shop plans can be used to build a wide variety of projects, from simple furniture to intricate decorative pieces. Here are some examples:

- Outdoor furniture: Plans are available for building benches, chairs, tables, and even swing sets.

- Indoor furniture: You can find plans for building coffee tables, nightstands, bookshelves, and more.

- Decorative items: Plans exist for creating picture frames, wall shelves, and decorative boxes.

- Storage solutions: Build custom cabinets, shelves, and organizers using shop plans.

Essential Elements of Woodworking Shop Plans

Woodworking shop plans are essential for creating successful projects. They provide a roadmap for your build, guiding you through each step and ensuring you have the necessary materials and tools. Understanding the key components of these plans is crucial for successful project completion.

Materials List

The materials list is the foundation of any woodworking shop plan. It Artikels every piece of wood, hardware, and other materials required for the project. This list helps you gather everything you need before starting, minimizing the risk of delays or unexpected expenses.

- Wood Types and Dimensions: The materials list specifies the types of wood, such as oak, pine, or plywood, along with their exact dimensions, including length, width, and thickness. This ensures you purchase the correct pieces for your project.

- Quantity: The list indicates the number of each type of wood needed. This helps you avoid overbuying or running out of materials mid-project.

- Hardware: The list includes all hardware, such as screws, nails, hinges, and drawer slides. This ensures you have all the necessary components for assembly.

- Other Materials: The list may also include other materials like glue, paint, stain, or finishing products.

Cutting Diagrams

Cutting diagrams provide visual instructions for cutting the wood pieces to the correct size and shape. These diagrams are essential for ensuring accurate cuts and proper assembly.

- Dimensions: The diagrams include precise dimensions for each cut, ensuring that all pieces fit together perfectly.

- Shape: The diagrams show the shape of each piece, including any curves, angles, or special features.

- Cutting Lines: Cutting lines are clearly marked on the diagrams, indicating where to make each cut.

- Labels: Pieces are often labeled with letters or numbers for easy identification and reference.

Assembly Instructions

Assembly instructions guide you through the process of putting the project together. They typically include step-by-step instructions with accompanying diagrams or illustrations.

- Sequence: The instructions specify the order in which to assemble the pieces, ensuring proper construction.

- Joints: Instructions detail the types of joints used, such as dado joints, mortise and tenon joints, or pocket holes, and how to create them.

- Fasteners: The instructions indicate the type and size of fasteners to use for each step, such as screws, nails, or glue.

- Tips and Tricks: Some instructions may include helpful tips or tricks for achieving a professional finish or overcoming potential challenges.

Additional Information

Woodworking shop plans may also include additional information to help you understand and complete the project successfully.

- Tool List: Some plans provide a list of tools required for the project, helping you gather everything before you start.

- Finishing Instructions: Plans may include instructions for finishing the project, such as sanding, staining, or painting.

- Safety Precautions: Plans often include safety precautions to help you work safely and avoid injuries.

- Troubleshooting Tips: Some plans may offer troubleshooting tips for common problems that may arise during construction.

Interpreting Woodworking Shop Plans

- Read Carefully: Before starting, carefully read through the entire plan to understand the project scope and the steps involved.

- Study Diagrams: Pay close attention to the cutting diagrams to ensure you understand the shapes and dimensions of each piece.

- Label Pieces: Label each piece of wood according to the cutting diagram for easy identification.

- Double-Check Measurements: Always double-check your measurements before making any cuts to ensure accuracy.

- Follow Instructions: Follow the assembly instructions carefully, taking each step in order.

- Seek Help: If you encounter any difficulties, don’t hesitate to seek help from experienced woodworkers or online resources.

Finding and Choosing Woodworking Shop Plans

You’ve decided to build your dream woodworking shop, and you’re ready to start planning. Now, you need to find the right woodworking shop plans to bring your vision to life.

Choosing the right plans is essential because they will guide you through every step of the process, from laying the foundation to installing the final fixtures. Let’s explore the various sources for finding woodworking shop plans and how to choose the best ones for your needs.

Sources for Woodworking Shop Plans

There are several great places to find woodworking shop plans. Each source has its own advantages and disadvantages, so it’s essential to weigh your options carefully.

- Online Retailers: Many online retailers offer a wide selection of woodworking shop plans, including both digital downloads and physical copies. Some popular retailers include Amazon, Etsy, and Woodcraft.

- Woodworking Magazines: Several woodworking magazines feature shop plans in their publications. These plans are often more detailed and specific to the magazine’s target audience. Popular woodworking magazines include Popular Woodworking, Fine Woodworking, and Woodworking Magazine.

- Libraries: Public libraries often have a collection of woodworking books that include shop plans. You can also find online resources through library databases, such as the Library of Congress or WorldCat.

- Woodworking Websites: Many woodworking websites offer free or paid plans for shop projects. These websites often feature user-submitted plans, so you can find a variety of options based on skill level and budget.

Advantages and Disadvantages of Different Sources

| Source | Advantages | Disadvantages |

|---|---|---|

| Online Retailers | Wide selection, convenience, easy to compare prices | May not be as detailed, potential for copyright issues |

| Woodworking Magazines | Detailed plans, specific to target audience, often include building tips and techniques | May require subscription, limited selection, plans may be outdated |

| Libraries | Free access, wide variety of books, often include detailed plans | May require membership, limited selection, plans may be outdated |

| Woodworking Websites | Free or paid plans, variety of options, often include user reviews | Quality can vary, potential for copyright issues, may require membership |

Choosing the Best Woodworking Shop Plans

When selecting woodworking shop plans, consider these factors:

- Your Skill Level: Choose plans that match your woodworking experience. If you’re a beginner, start with simple plans and gradually work your way up to more complex projects.

- Your Budget: Consider the cost of materials and tools when choosing plans. Some plans may require specialized equipment or expensive materials, which can significantly impact your budget.

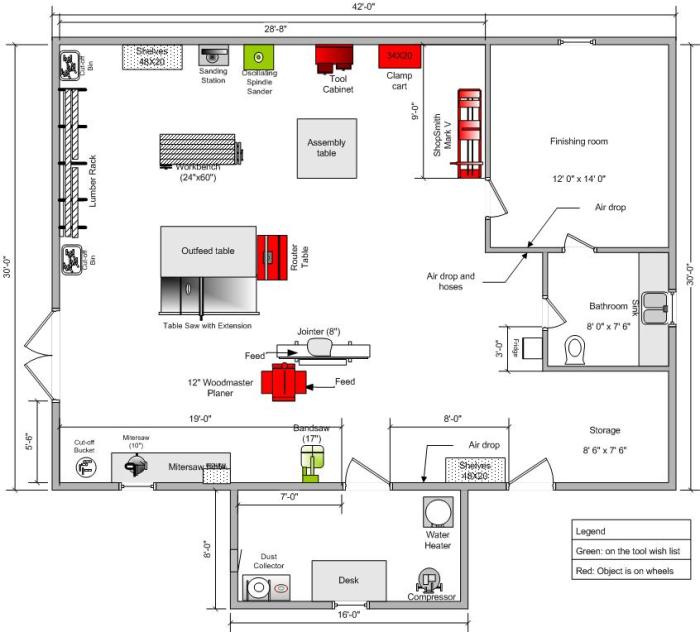

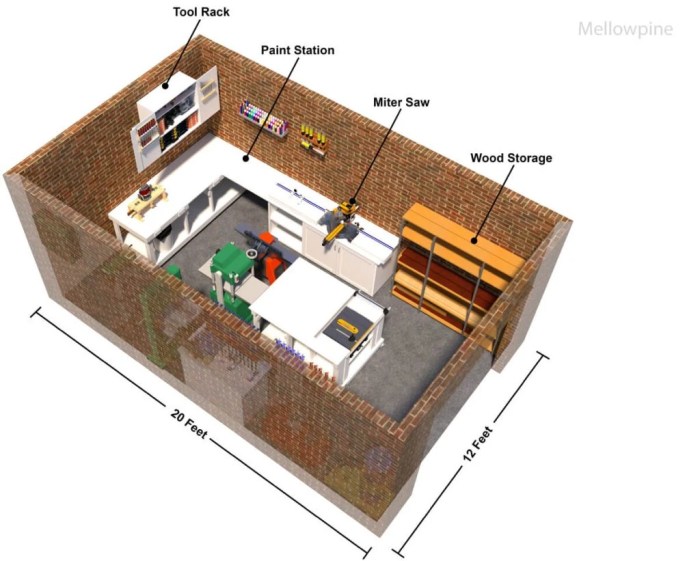

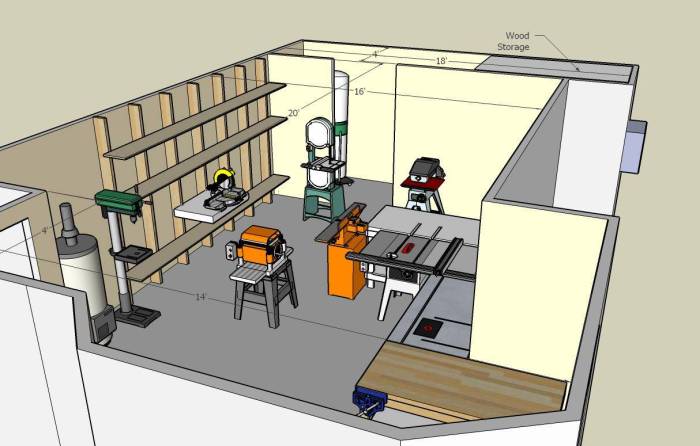

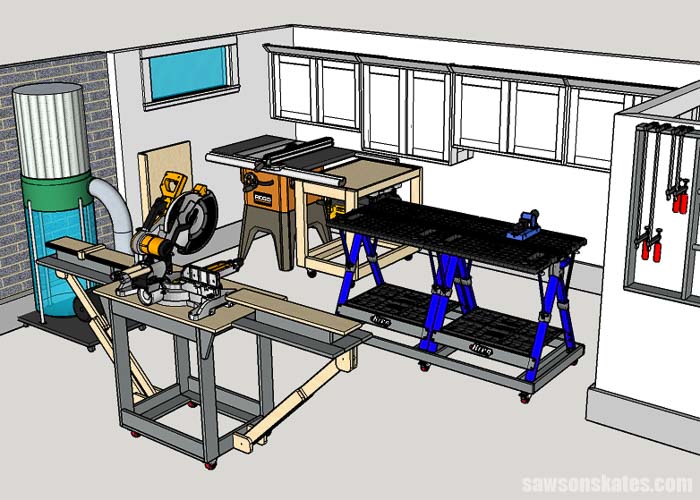

- Available Space: Make sure the plans fit within your available space. Consider the overall dimensions of the shop, including the size of the workbench, storage areas, and any other equipment you plan to install.

- Your Needs: Think about the specific features you want in your woodworking shop. Do you need a dedicated space for finishing, a large dust collection system, or a specific type of lighting?

- Reviews and Ratings: Read reviews and ratings from other woodworkers who have used the plans. This can help you assess the quality and complexity of the plans.

Using Woodworking Shop Plans Effectively

Woodworking shop plans are more than just blueprints; they’re your roadmap to success. They provide a detailed framework for building your project, guiding you through each step. But, using these plans effectively requires understanding their purpose and knowing how to navigate them.

A Step-by-Step Process for Using Woodworking Shop Plans

Using woodworking shop plans effectively involves a methodical approach, ensuring accuracy and smooth project execution. The following steps provide a structured framework for utilizing plans:

- Review the Plan: Begin by carefully studying the plan, understanding its components and their purpose. This includes analyzing the materials list, cutting diagrams, assembly instructions, and any additional information provided.

- Gather Materials: Based on the materials list, gather all the necessary materials. Ensure that you have the correct quantities and types of wood, hardware, and finishing supplies.

- Prepare the Workspace: Set up your workspace with adequate lighting, ventilation, and a clean and organized layout. Ensure you have the necessary tools readily available, including saws, drills, sanders, clamps, and measuring tools.

- Cut the Wood: Using the cutting diagrams provided in the plan, carefully cut the wood to the specified dimensions. It’s crucial to double-check measurements before making each cut to avoid mistakes.

- Assemble the Project: Follow the assembly instructions step-by-step, ensuring that each joint is properly aligned and secured. Use appropriate fasteners, glue, and clamps as indicated in the plan.

- Sand and Finish: Once the project is assembled, sand it to remove any rough edges and imperfections. Apply the desired finish, such as paint, stain, or varnish, following the instructions provided in the plan or your preferred finishing technique.

Adapting Woodworking Shop Plans

While woodworking shop plans provide a solid foundation, you might need to adapt them to suit your specific needs or preferences. This involves:

- Material Substitution: If a specific wood type is unavailable or you prefer to use a different material, make sure the substitute has similar properties, such as strength and grain structure. Adjust the plan accordingly to account for any changes in dimensions or weight.

- Dimension Adjustments: You might need to adjust the dimensions of the project to fit your space or personal taste. However, ensure that any modifications maintain the structural integrity of the piece.

- Design Modifications: Feel free to add your personal touch by incorporating design elements that complement your style. This could involve changing the shape of a component, adding decorative details, or altering the overall design.

Using Woodworking Shop Plans with Other Resources

Woodworking shop plans are not meant to be used in isolation. You can enhance your understanding and skills by combining them with other resources:

- Online Tutorials: Explore online tutorials for specific techniques or joinery methods that are not fully explained in the plan. These resources can provide visual demonstrations and step-by-step instructions, enriching your learning experience.

- Woodworking Books: Consult woodworking books for detailed information on materials, tools, and techniques. These books often provide valuable insights and practical tips that can complement your woodworking journey.

- Woodworking Forums: Engage with other woodworkers online to seek advice, share experiences, and troubleshoot any challenges you encounter while building your project.

Safety Considerations for Woodworking Shop Plans

Woodworking is a rewarding hobby, but it can also be dangerous if safety is not a top priority. Understanding the potential hazards and implementing appropriate safety measures is crucial for enjoying woodworking without risking injury. Woodworking shop plans can play a vital role in promoting a safe working environment by providing detailed instructions and guidance on setting up a shop, using tools, and executing projects.

Identifying Potential Hazards

Woodworking projects involve a variety of tools and materials that can pose potential hazards if not handled properly.

- Sharp tools: Saws, chisels, planes, and knives can cause severe cuts and lacerations.

- Rotating machinery: Table saws, jointers, and planers can cause severe injuries if fingers or hands come into contact with the rotating blades.

- Dust and fumes: Woodworking dust can be harmful to the respiratory system, and certain wood types may release toxic fumes.

- Heavy objects: Moving heavy pieces of wood or equipment can lead to strains, sprains, or back injuries.

- Electrical hazards: Improperly wired tools or damaged cords can cause electrical shocks or fires.

Safety Measures in Woodworking Shop Plans

Woodworking shop plans can incorporate various safety measures to minimize risks and create a safer working environment.

- Tool safety instructions: Plans should include detailed instructions on how to use each tool safely, including proper setup, operation, and maintenance.

- Protective equipment recommendations: Plans should emphasize the importance of wearing appropriate personal protective equipment (PPE), such as safety glasses, hearing protection, dust masks, and gloves.

- Shop layout and organization: Plans should Artikel a well-organized and safe shop layout, with adequate lighting, clear walkways, and designated storage areas for tools and materials.

- Fire safety guidelines: Plans should address fire safety by including recommendations for fire extinguishers, smoke detectors, and proper disposal of flammable materials.

- Emergency procedures: Plans should include emergency procedures for handling accidents or injuries, such as first aid instructions and contact information for emergency services.

Safety Recommendations for Using Woodworking Tools and Equipment

Here are some general safety recommendations for using woodworking tools and equipment:

- Always wear appropriate PPE: This includes safety glasses, hearing protection, dust masks, and gloves, depending on the task.

- Use tools only for their intended purpose: Avoid using tools for tasks they are not designed for, as this can lead to accidents.

- Keep tools sharp and in good working condition: Dull tools are more likely to slip and cause injuries. Regular maintenance and sharpening are essential.

- Use push sticks and feather boards: These devices help to keep your hands away from the cutting edge of tools like table saws and jointers.

- Use a dust collection system: This helps to reduce the amount of dust in the air, which can be harmful to your health.

- Work in a well-lit area: Adequate lighting helps to prevent accidents by improving visibility.

- Never work alone: Always have someone nearby who can assist in case of an emergency.

- Be aware of your surroundings: Pay attention to your surroundings and be aware of potential hazards.

- Take breaks when needed: Fatigue can lead to accidents. Take breaks to rest and avoid working when you are tired.

- Follow all safety instructions provided in the woodworking shop plans: The plans are designed to guide you towards safe practices, so follow them diligently.

Examples of Woodworking Shop Plans

This section will provide a table showcasing woodworking shop plans, categorized by project type, source, difficulty level, and key features. This will give you a clear idea of the diverse plans available and help you choose the right one for your needs.

Examples of Woodworking Shop Plans

Woodworking shop plans come in a variety of types, each tailored to specific projects and skill levels. Here is a table showcasing some examples:

| Project Type | Plan Source | Difficulty Level | Key Features |

|---|---|---|---|

| Workbench | Woodworking.org | Beginner | Solid construction, adjustable height, multiple work surfaces |

| Small Storage Cabinet | Popular Woodworking | Beginner | Easy to assemble, compact design, versatile storage options |

| Outdoor Picnic Table | Ana White | Intermediate | Durable construction, weather-resistant finish, comfortable seating |

| Custom Bookshelf | Woodworking.org | Intermediate | Tailored to specific space, adjustable shelves, elegant design |

Advanced Techniques for Using Woodworking Shop Plans

Woodworking shop plans can be taken to the next level with the help of technology and a few strategic approaches. These advanced techniques not only enhance the accuracy and efficiency of your projects but also open up possibilities for greater creativity and design flexibility.

Using Computer-Aided Design (CAD) Software

CAD software offers a powerful tool for creating and modifying woodworking shop plans. It allows for precise measurements, detailed drawings, and the ability to easily manipulate designs. Here are some key benefits of using CAD software:

* Increased Accuracy: CAD software eliminates the potential for human error in measurements and calculations. It enables you to create precise drawings that can be easily scaled and modified.

* Enhanced Visualization: CAD software allows you to create 3D models of your woodworking projects, providing a realistic preview of the final product. This helps you visualize the design and identify any potential issues before starting construction.

* Improved Efficiency: CAD software automates many of the repetitive tasks involved in creating woodworking shop plans, such as drawing lines, creating shapes, and calculating dimensions. This saves time and effort, allowing you to focus on the creative aspects of your projects.

* Easy Modification: With CAD software, it’s easy to make changes to your woodworking shop plans, allowing you to experiment with different designs and optimize your project for functionality and aesthetics.

- Popular CAD software options for woodworking include: SketchUp, AutoCAD, and SolidWorks. Each program offers a unique set of features and capabilities, so it’s important to choose one that best suits your needs and skill level.

- Using CAD software effectively requires some initial learning and practice. There are numerous online tutorials and resources available to help you get started.

- Consider the specific features and capabilities of different CAD software programs. Some programs are more suited for simple projects, while others offer advanced features for complex designs.

Utilizing 3D Printing for Prototyping

3D printing has revolutionized the prototyping process, allowing woodworkers to create physical models of their designs before committing to the actual construction. Here’s how 3D printing can benefit woodworking shop plans:

* Testing and Refinement: 3D printing allows you to create prototypes of your woodworking designs, enabling you to test the fit, functionality, and overall aesthetics before proceeding with the final project. This helps identify any design flaws or areas that need improvement.

* Visualizing Complex Designs: 3D printing can be particularly helpful for visualizing intricate designs or complex joinery techniques. The physical model provides a tangible representation of the design, making it easier to understand and identify potential issues.

* Experimenting with Materials: 3D printing allows you to experiment with different materials and finishes before making a final decision. This helps ensure that the chosen materials will work well for your project and meet your aesthetic preferences.

* Creating Custom Fixtures: 3D printing can be used to create custom jigs, fixtures, and templates for woodworking projects. This allows you to tailor your tools and equipment to the specific requirements of your design, improving accuracy and efficiency.

- There are various 3D printing technologies available, each with its own advantages and limitations. Fused deposition modeling (FDM) is a common and affordable option for prototyping woodworking designs.

- 3D printing services are widely available, offering an alternative to purchasing your own 3D printer. These services allow you to upload your design files and receive a printed prototype.

- Consider the size and complexity of your woodworking project when choosing a 3D printing service. Some services have limitations on the size and materials they can print.

Optimizing Woodworking Shop Plans for Efficiency and Accuracy

To maximize the effectiveness of your woodworking shop plans, it’s crucial to optimize them for efficiency and accuracy. Here are some tips to achieve this:

- Break down complex projects into smaller, manageable steps. This makes it easier to plan each stage of the project and ensures that you have a clear understanding of the overall process.

- Use a consistent system for labeling and organizing your woodworking shop plans. This helps you quickly find the information you need and avoid confusion.

- Include detailed cut lists and material lists in your woodworking shop plans. This helps you ensure that you have all the necessary materials before starting the project and eliminates the need for last-minute trips to the lumberyard.

- Utilize templates and jigs to improve accuracy and consistency. These tools help you create precise cuts and ensure that all the components of your project fit together perfectly.

- Consider using a digital cutting tool, such as a CNC router or laser cutter. These tools offer high levels of precision and speed, making them ideal for complex woodworking projects.

Conclusive Thoughts

With the right woodworking shop plans and a touch of creativity, you can transform your ideas into stunning reality. Remember, woodworking is a journey of discovery, and every project, no matter how big or small, is an opportunity to learn, grow, and build something truly unique. So, pick up your tools, choose your plans, and let the woodworking adventure begin!

Q&A

What are the benefits of using woodworking shop plans?

Using plans ensures accuracy, saves time, reduces waste, and helps you avoid common mistakes. They also provide detailed instructions and diagrams, making the process easier to follow.

Where can I find free woodworking shop plans?

Many websites offer free woodworking plans, including Ana White, Woodworking for Mere Mortals, and Instructables. Libraries and woodworking magazines are also great resources.

How do I choose the right woodworking shop plans for my project?

Consider your skill level, the complexity of the project, and the available materials. Look for plans with clear instructions, detailed diagrams, and a materials list.

Woodworking shop plans can be a great way to organize your space and make the most of your tools. But sometimes, you just want to get outside and work with wood in the fresh air. If that’s the case, you might want to check out some outdoor woodworking plans that can help you build everything from a simple picnic table to a complex gazebo.

Once you’ve got your outdoor space set up, you can use your shop plans to build more intricate projects that you can enjoy in your new woodworking haven.