Woodworking shop projects sets the stage for this enthralling narrative, offering readers a glimpse into a world where creativity meets craftsmanship. This comprehensive guide delves into the fascinating realm of woodworking, covering everything from essential tools and techniques to inspiring design concepts and community resources. Whether you’re a seasoned woodworker or a curious beginner, this journey will ignite your passion for transforming wood into stunning creations.

We’ll explore the fundamentals of setting up a woodworking shop, covering essential tools, safety practices, and a diverse range of wood types. From there, we’ll embark on a progressive path, starting with beginner-friendly projects that build confidence and progress to intermediate and advanced projects that challenge your skills and expand your creative horizons. Along the way, we’ll delve into the artistry of woodworking design, emphasizing aesthetics, functionality, and the importance of ergonomic considerations.

Woodworking Shop Essentials

A well-equipped woodworking shop is a haven for creativity and craftsmanship. Having the right tools and equipment is essential for tackling various woodworking projects, from simple repairs to intricate furniture pieces.

Essential Tools and Equipment

A well-stocked woodworking shop should include a variety of hand tools and power tools to handle different tasks.

- Hand Tools: Hand tools form the foundation of woodworking, offering precise control and versatility. Essential hand tools include:

- Measuring Tools: Measuring tapes, rulers, calipers, and combination squares are essential for accurate measurements.

- Marking Tools: Pencils, marking gauges, and dividers help transfer measurements and create precise lines.

- Cutting Tools: Saws, chisels, planes, and knives are used for shaping and cutting wood.

- Clamps and Vises: Clamps secure workpieces during cutting and assembly, while vises provide a stable platform for precise work.

- Drilling Tools: Hand drills and drill presses are used for creating holes in wood.

- Sanding Tools: Sandpaper, sanding blocks, and orbital sanders are essential for smoothing and finishing wood surfaces.

- Power Tools: Power tools enhance efficiency and speed in woodworking. Essential power tools include:

- Circular Saw: A versatile tool for cutting wood to length and making rip cuts.

- Table Saw: Provides accurate and precise cuts, particularly for ripping lumber to width.

- Jointer: Used for flattening and smoothing rough-cut lumber.

- Planer: Reduces the thickness of lumber and creates a uniform surface.

- Router: A versatile tool for shaping edges, creating grooves, and carving designs.

- Band Saw: Used for intricate curves and shaping wood.

- Scroll Saw: A specialized saw for intricate cutting and scrollwork.

- Belt Sander: Provides aggressive sanding for removing large amounts of material.

- Disc Sander: Used for shaping and smoothing wood surfaces.

- Drill Press: Provides accurate and precise drilling, especially for creating multiple holes in the same location.

Safety Gear and Practices

Safety should be a top priority in a woodworking shop.

- Eye Protection: Safety glasses or goggles are essential to protect eyes from flying debris.

- Hearing Protection: Earplugs or earmuffs are crucial to prevent hearing damage from loud machinery.

- Respiratory Protection: Dust masks or respirators are necessary to protect against sawdust and wood dust.

- Hand Protection: Gloves should be worn when handling sharp tools or working with abrasive materials.

- Foot Protection: Sturdy work boots with steel toes are recommended to protect feet from falling objects or sharp tools.

- Proper Clothing: Loose-fitting clothing should be avoided, and long hair should be tied back to prevent entanglement in machinery.

Types of Wood

Wood is a natural material with a wide range of properties, making it suitable for various woodworking projects.

| Wood Type | Characteristics | Applications |

|---|---|---|

| Oak | Hard, strong, durable, with beautiful grain patterns. | Furniture, flooring, cabinets, boat building. |

| Maple | Hard, strong, with a fine, even grain. | Furniture, flooring, cabinets, musical instruments. |

| Cherry | Hard, strong, with a reddish-brown color that darkens with age. | Furniture, cabinets, trim work. |

| Walnut | Hard, strong, with a rich brown color and distinctive grain patterns. | Furniture, cabinets, gunstocks. |

| Pine | Soft, lightweight, inexpensive, with a distinctive knotty grain. | Construction, framing, furniture, crafts. |

| Cedar | Lightweight, aromatic, naturally insect-resistant. | Outdoor furniture, siding, decking, crafts. |

| Redwood | Resistant to rot and decay, with a distinctive reddish-brown color. | Outdoor furniture, siding, decking, fencing. |

| Mahogany | Hard, strong, with a beautiful reddish-brown color and distinctive grain patterns. | Furniture, cabinets, boat building. |

| Birch | Hard, strong, with a fine, even grain. | Furniture, cabinets, plywood, veneers. |

Beginner Woodworking Projects

Starting your woodworking journey can be exciting and rewarding. Simple projects are a great way to learn the basics and gain confidence. This section will guide you through designing and building a beginner-friendly project, providing detailed steps, a materials list, and essential techniques.

Choosing a Beginner Project

Choosing the right project is crucial for a successful start. A simple project like a small wooden box or a cutting board offers a manageable scope and allows you to practice basic techniques. These projects are relatively quick to complete, giving you a sense of accomplishment early on.

Designing a Simple Wooden Box

This project will guide you through building a small wooden box. This project will allow you to practice cutting, sanding, and finishing techniques, essential skills for any woodworker.

Materials List

- Wood: 1/2-inch thick plywood or hardwood boards (pine, oak, maple)

- Wood glue

- Screws (1-inch or 1.5-inch)

- Sandpaper (80, 120, 220 grit)

- Wood finish (stain, varnish, or paint)

- Measuring tape

- Pencil

- Saw (hand saw, circular saw, or jigsaw)

- Clamps

- Drill with drill bits

- Screwdriver

Cutting the Wood

- Measure and mark the wood according to the dimensions of your box.

- Use a saw to cut the wood to the desired length and width. Ensure the cuts are straight and precise.

Assembling the Box

- Apply wood glue to the edges of the box pieces.

- Clamp the pieces together, ensuring they are aligned correctly.

- Pre-drill holes for screws to prevent splitting the wood.

- Screw the pieces together to secure the box.

Sanding and Finishing

- Sand the box with 80-grit sandpaper to smooth out any rough edges.

- Progress to 120-grit and then 220-grit sandpaper for a smoother finish.

- Apply your chosen wood finish according to the manufacturer’s instructions.

Basic Woodworking Techniques

Cutting

Cutting wood accurately and safely is essential for any woodworking project.

- Hand Saw: A hand saw is a versatile tool for cutting wood. It requires practice to achieve straight and precise cuts.

- Circular Saw: A circular saw provides a more efficient way to cut wood, especially for straight lines. Use a guide rail for accurate cuts.

- Jigsaw: A jigsaw is ideal for cutting curves and intricate shapes in wood.

Sanding

Sanding smooths out rough surfaces and prepares the wood for finishing.

- Sandpaper: Sandpaper comes in various grits, with lower grits (e.g., 80 grit) for rough sanding and higher grits (e.g., 220 grit) for finer sanding.

- Sanding Block: A sanding block provides a flat and even surface for sanding, ensuring a consistent finish.

Finishing

Finishing protects the wood and enhances its appearance.

- Stains: Stains penetrate the wood, adding color and highlighting the grain.

- Varnishes: Varnishes create a protective layer that seals the wood and provides a glossy finish.

- Paints: Paints provide a solid color coating, covering the natural wood grain.

Selecting Wood and Tools

Wood Selection

The type of wood you choose will influence the project’s appearance and durability.

- Hardwoods: Hardwoods like oak, maple, and cherry are durable and offer a beautiful grain pattern. They are often more expensive than softwoods.

- Softwoods: Softwoods like pine and fir are less expensive and easier to work with. They are suitable for beginner projects.

- Plywood: Plywood is a versatile material made of thin layers of wood veneer. It is relatively inexpensive and stable, making it suitable for various projects.

Tool Selection

The tools you need will depend on the project’s complexity and your budget.

- Essential Tools: A saw, hammer, screwdriver, measuring tape, pencil, and sandpaper are essential for most woodworking projects.

- Optional Tools: A drill, router, and planer can expand your woodworking capabilities but are not essential for beginner projects.

Intermediate Woodworking Projects: Woodworking Shop Projects

Stepping up from basic woodworking projects, intermediate projects offer a chance to explore more complex techniques and create more intricate pieces. These projects often involve a combination of skills and require a greater understanding of woodworking principles.

Intermediate Woodworking Projects

A range of intermediate woodworking projects can challenge and refine your skills. Here are a few ideas, arranged in increasing order of complexity:

- Simple Storage Boxes: These projects introduce you to joinery techniques like dadoes, rabbets, and miter joints. You can experiment with different wood types and finishes to create unique boxes for storing small items.

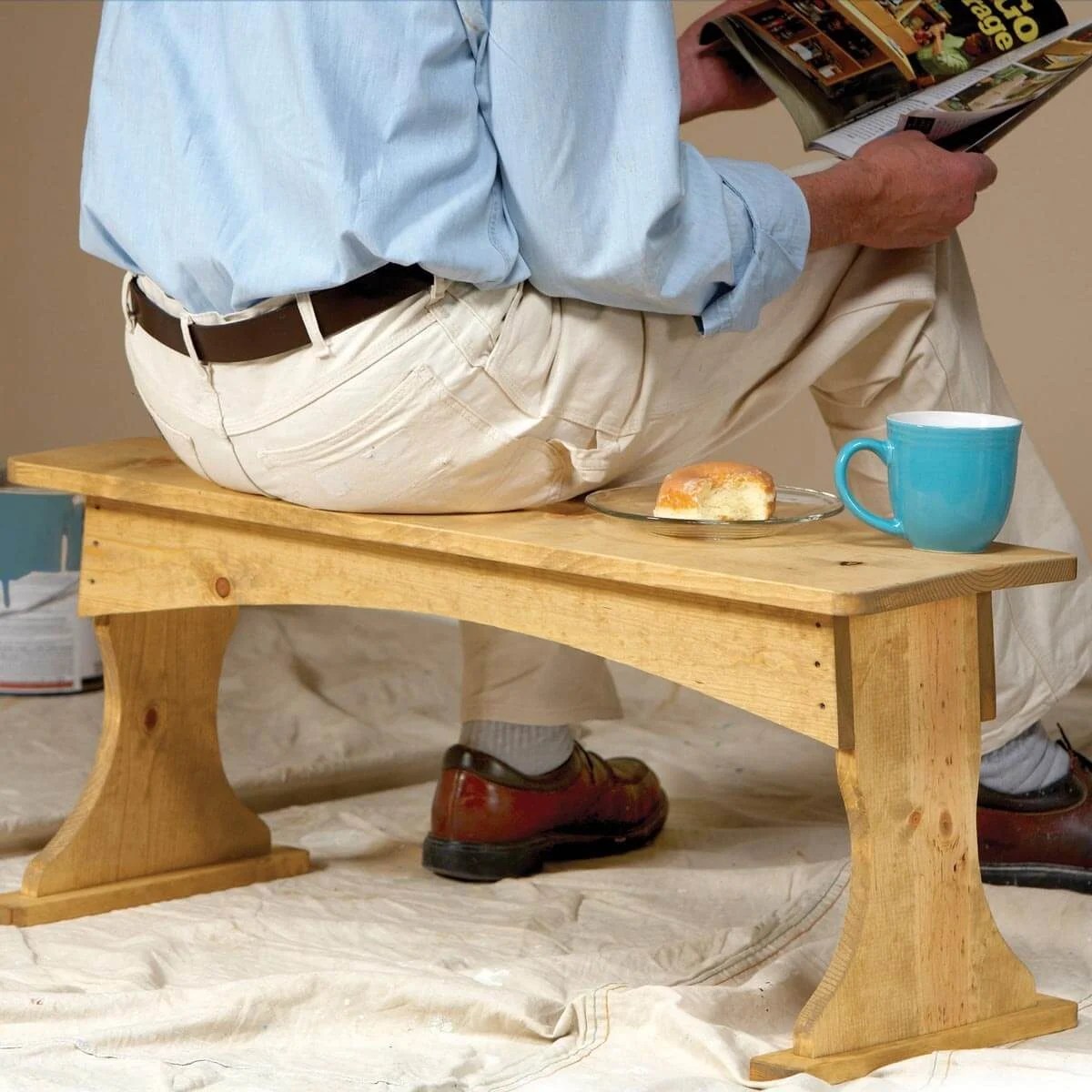

- Small Furniture: Building a small table, chair, or bench requires planning and precise cuts. You’ll learn to work with larger pieces of wood and incorporate more intricate joinery.

- Decorative Items: Creating decorative items like picture frames, wall shelves, or cutting boards allows you to experiment with different wood patterns and finishes. You can also explore techniques like inlay or marquetry.

- Outdoor Projects: Building a birdhouse, planter box, or small outdoor furniture involves working with weather-resistant materials and considering design for outdoor use.

Advanced Woodworking Techniques

Advanced woodworking techniques add complexity and sophistication to your projects.

- Joinery: Joinery techniques like mortise and tenon, dovetail, and box joints create strong and aesthetically pleasing connections between wood pieces. These joints are often used in furniture making and other intricate projects.

- Carving: Wood carving involves shaping and detailing wood using hand tools like chisels and gouges. It can be used to create decorative elements, sculptures, or functional objects like spoons and bowls.

- Turning: Wood turning uses a lathe to shape and create round objects like bowls, vases, and spindles. It requires precision and control to achieve smooth, symmetrical forms.

Creating a Detailed Woodworking Plan

A detailed woodworking plan is essential for success. It Artikels the dimensions, materials, and assembly steps of your project.

- Dimensions: Precisely measure and record all dimensions of your project. Use a scale drawing or computer-aided design (CAD) software to visualize the design.

- Materials: Select appropriate wood species and sizes based on the project’s requirements. Consider the wood’s properties like hardness, grain, and durability.

- Assembly Steps: Break down the project into manageable steps. Include detailed instructions for cutting, joining, and finishing. Consider the order of operations and any necessary tools or equipment.

Advanced Woodworking Projects

Stepping into the realm of advanced woodworking projects is like entering a new level of craftsmanship. These projects often demand specialized skills, meticulous attention to detail, and a toolbox full of advanced tools. They’re not just about building something functional; they’re about creating pieces that showcase your mastery of the craft and leave a lasting impression.

Furniture Making

Furniture making is a highly sought-after skill in woodworking. It involves creating pieces that are both functional and aesthetically pleasing, demanding a deep understanding of joinery, wood selection, and finishing techniques.

- Types of Furniture: Furniture projects range from simple chairs and tables to elaborate cabinets and dressers. The complexity of the project depends on the design, materials, and construction techniques used.

- Joinery Techniques: Advanced joinery techniques, such as mortise and tenon, dovetail, and box joints, are essential for building sturdy and durable furniture. These techniques require precision and accuracy to ensure a strong and lasting bond between the pieces of wood.

- Wood Selection: The choice of wood plays a crucial role in the final look and durability of furniture. Hardwoods like oak, maple, and cherry are popular choices for furniture making due to their strength, beauty, and durability.

- Finishing Techniques: Finishing techniques like sanding, staining, and varnishing enhance the appearance and protect the wood. Advanced furniture makers may use specialized finishes to achieve unique effects, such as hand-rubbed oil finishes or lacquer.

Custom Cabinetry

Custom cabinetry is another area where advanced woodworking skills shine. It involves designing and building cabinets that perfectly fit a specific space and meet the client’s unique requirements.

- Design and Planning: The first step in custom cabinetry is to carefully design the cabinets to meet the client’s needs and the available space. This involves taking measurements, considering the layout, and choosing the appropriate materials.

- Construction Techniques: Custom cabinets often incorporate complex joinery techniques and specialized tools to ensure precise fit and durability. This may involve using a router table for intricate cuts, a dado stack for shelf construction, and a table saw for accurate panel cutting.

- Finishing and Installation: Once the cabinets are built, they are carefully finished to match the desired aesthetic and protect the wood. The final step involves installing the cabinets in the designated space, ensuring a perfect fit and alignment.

Woodworking Styles and Techniques

Different woodworking styles and techniques are used in advanced projects, each with its own unique characteristics and aesthetic appeal.

- Traditional Woodworking: Traditional woodworking techniques, often passed down through generations, emphasize hand tools and meticulous craftsmanship. These techniques often involve using hand planes, chisels, and saws to create intricate details and joinery.

- Modern Woodworking: Modern woodworking often incorporates power tools and computer-aided design (CAD) software to create precise and efficient designs. Modern techniques may also involve using innovative materials and finishes.

- Rustic Woodworking: Rustic woodworking emphasizes the natural beauty of wood, often incorporating rough-hewn timbers and reclaimed wood. Rustic projects may feature distressed finishes and unique imperfections that add character and charm.

Building a Challenging Woodworking Project: A Step-by-Step Guide, Woodworking shop projects

Building a challenging woodworking project requires meticulous planning, precise execution, and a deep understanding of woodworking principles. Here’s a step-by-step guide to help you tackle a complex project:

- Design and Planning: Begin by carefully designing your project, considering the overall dimensions, materials, and construction techniques. Create detailed drawings or sketches to visualize the final product and ensure all components fit together correctly.

- Materials Selection: Choose the right wood for your project, considering its strength, grain pattern, and workability. Ensure the wood is properly seasoned and free of defects.

- Cutting and Shaping: Cut and shape the wood according to your design, using a combination of hand tools and power tools. Pay close attention to accuracy and precision to ensure a tight fit and a professional finish.

- Joinery: Create strong and durable joints using appropriate techniques for your project. This may involve mortise and tenon joints, dovetail joints, or other specialized joinery methods.

- Assembly: Assemble the project, carefully aligning and securing the components using glue, screws, or dowels. Ensure the project is square and level throughout the assembly process.

- Finishing: Sand the project smooth, applying multiple grits of sandpaper to remove any imperfections. Apply a finish, such as stain, varnish, or paint, to protect the wood and enhance its appearance.

Woodworking Techniques and Finishes

Woodworking is a craft that involves shaping and assembling wood to create functional and decorative objects. Mastering various techniques and finishes is crucial for achieving professional-quality results.

Hand Tool Techniques

Hand tools are essential for woodworking, offering precision and control.

- Chisels are used for shaping and removing wood. They come in various sizes and shapes, each suited for specific tasks.

- Planes are used for smoothing and flattening wood surfaces. They are available in different sizes and blade angles.

- Saws are used for cutting wood. Hand saws are versatile, allowing for precise cuts in various directions.

- Mallet is used for striking chisels and other tools, providing controlled force.

- Clamps are used to hold wood pieces together securely during assembly.

Power Tool Applications

Power tools significantly enhance efficiency and precision in woodworking.

- Circular Saw is a versatile tool used for making straight cuts and ripping wood.

- Jigsaw is used for making intricate curves and shapes.

- Router is used for shaping edges, creating grooves, and performing various other tasks.

- Belt Sander is used for smoothing and shaping large surfaces.

- Drill Press is used for drilling holes with precision.

Wood Finishes

Wood finishes enhance the appearance and durability of wood.

| Finish | Properties | Applications | Methods of Application |

|---|---|---|---|

| Oil-Based Polyurethane | Durable, water-resistant, UV-resistant | Floors, furniture, cabinets | Brush, roller, spray |

| Water-Based Polyurethane | Durable, water-resistant, low VOCs | Floors, furniture, cabinets | Brush, roller, spray |

| Lacquer | Hard, durable, fast-drying | Furniture, musical instruments | Spray |

| Shellac | Natural, durable, easy to repair | Furniture, floors, antiques | Brush, spray |

| Varnish | Durable, water-resistant, UV-resistant | Floors, furniture, cabinets | Brush, roller, spray |

Sanding

Sanding is a crucial step in preparing wood for finishing.

- Sanding removes imperfections, such as scratches and tool marks, creating a smooth surface.

- Use progressively finer grits, starting with a coarse grit to remove larger imperfections and ending with a fine grit for a smooth finish.

- Sand with the grain to avoid scratches and create a uniform finish.

- Sanding dust can be harmful, so wear a respirator and eye protection.

Staining

Staining adds color and depth to wood.

- Water-based stains are easy to clean up and dry quickly.

- Oil-based stains penetrate deeper into the wood, resulting in a richer color.

- Apply stains evenly, using a brush, rag, or sprayer.

- Wipe off excess stain to prevent uneven color and blotching.

Varnishing

Varnishing protects wood from moisture, scratches, and UV damage.

- Apply varnish in thin coats, allowing each coat to dry completely before applying the next.

- Use a brush, roller, or sprayer, depending on the project and desired finish.

- Avoid dust and debris during the drying process.

- Sand lightly between coats to create a smooth, even finish.

Tips for Professional-Quality Finishes

- Prepare the wood surface thoroughly by sanding and cleaning to remove dust and debris.

- Use high-quality finishes, as they will provide better protection and durability.

- Apply finishes in a well-ventilated area, away from direct sunlight and dust.

- Practice on scrap wood to get a feel for the finish and application technique.

- Be patient, as finishing takes time and multiple coats.

Ending Remarks

By embracing the rich tapestry of woodworking techniques, design principles, and community resources, you’ll unlock the potential to create extraordinary woodworking projects that reflect your unique style and craftsmanship. So, grab your tools, gather your inspiration, and join us on this exciting journey into the world of woodworking shop projects!

Questions Often Asked

What are some common woodworking mistakes beginners make?

Common mistakes include rushing the process, not using proper safety gear, and not measuring accurately. It’s important to take your time, prioritize safety, and double-check your measurements to avoid costly errors.

How can I find woodworking plans for my projects?

There are many online resources for woodworking plans, including websites, blogs, and even YouTube channels. You can also find plans in woodworking magazines and books.

What are the best wood finishes for different projects?

The best wood finish depends on the type of wood, the project’s purpose, and your desired aesthetic. Popular finishes include oil-based polyurethanes, water-based polyurethanes, and waxes.

Woodworking shop projects are a great way to unleash your creativity and build something unique. If you’re looking for inspiration, check out some cool woodworking projects to get your ideas flowing. Once you’ve got a project in mind, you can start planning your woodworking shop layout and gathering the tools and materials you’ll need.